Abstract

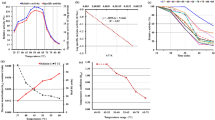

A tannase yielding bacterial strain was isolated from soil sample collected from the area situated nearby small-scale tannery. It was identified as Pseudomonas aeruginosa IIIB 8914. The bacterial strain produced extra-cellular tannase under sub-merged fermentation (Smf) using amla (Phyllanthus emblica), keekar (Acacia nilotica), jamoa (Eugenia cuspidate) and jamun (Syzygium cumini) leaves. Among different substrates, amla and keekar leaves resulted in maximal extra-cellular production of tannase. Various process parameters were studied to optimize the extra-cellular yield of tannase under Smf. Maximum yield of tannase i.e., 13.65 and 12.90 U/ml was obtained when Smf was carried out using amla and keekar leaves (2% w/v) respectively in minimal media supplemented with MgSO4·7H2O (amla)/HgCl2 (keekar), NH4NO3 and 0.2% Tween 80; inoculated with 2% cell suspension, and incubated at 37°C for 24 h. The bacterial strain produced about 2 times (13.65 U/ml) higher yield of tannase than the highest reported yield of tannase (6 U/ml). Our finding suggests that agro residues in the form of amla and keekar leaves can be one of the best and cost effective alternatives to the costly pure tannic acid for industrial production of microbial tannase.

Similar content being viewed by others

References

Aguilar CN, Augur C, Favela-Torre E, Viniega-González G (2001) Production of tannase by Aspergillus niger Aa-20 in submerged and solid state fermentation: influence of glucose and tannic acid. J Ind Microbiol Biotechnol 26(5):296–302

Aguilar CN, Rodríguez R, Gutiérrez-Sánchez G, Augur C, Favela-Torres E, Prado-Barragan LA, Ramírez-Coronel A, Contreras-Esquivel JC (2007) Microbial Tannases: advances and perspectives. Appl Microbiol Biotechnol 76(1):47–59

Ayed L, Hamdi M (2002) Culture conditions of tannase production by Lactobacillus plantaraum. Biotechnol Lett 24/21(3):1763–1765

Banerjee D, Pati BR (2007) Optimization of tannase production by Aureobasidium pullulans DBS 66. J Microbiol Biotechnol 17(6):1049–1053

Barthomeuf C, Regerat F, Pourrat H (1994) Production, purification and characterization of tannase from Aspergillus niger LCF8. J Ferment Technol 77:137–142

Battestin V, Macedo GA (2007) Effects of temperature, pH and additives on the activity of tannase produced by Paecilomyces variotii. Electron J Biotech 10(2):191–199

Bradoo S, Gupta R, Saxena RK (1997) Parametric optimization and biochemical regulation of extracellular tannase from Aspergillus japonicus. Proc Biochem 32(2):135–139

Das Mohapatra PK, Mondal KC, Pati BR (2006) Production of tannase through submerged fermentation of tannin-containing plant extracts by Bacillus licheniformis KBR6. Pol J Microbiol 55(4):297–301

Deschamps A, Otuk G, Lebeault J (1983) Production of tannase and degradation of chestnut tannin by bacteria. J Ferment Technol 61:55–59

Haggerman AE, Butler LG (1978) Protein precipitation method for determination of tannins. J Agric Food Chem 26:809–812

Kar B, Banerjee R, Bhattacharyya BC (2003) Effect of additives on the behavioral properties of tannin acyl hydrolase. Proc Biochem 38(9):1395–1401

Kasieczka BM, Kuk K, Kalinowska K, Turkiewicz M (2007) Purification and characterization of two cold-adapted extracellular tannin acyl hydrolases from an Antarctic strain Verticillium sp. P9. Appl Microbiol Biotechnol 77(1):77–89

Kim TU, Gu JY, Jeong JY, Bum SM, Shin YC (1995) Purification and characterization of a maltotetraose forming alkaline a-amylase from an alkalophilic Bacillus strain GM8901. Appl Environ Microbiol 61:3105–3112

Kumar RA, Gunasekaran P, Lakshmanan M (1999) Biodegradation of tannic acid by Citrobacter freundii isolated from a tannery effluent. J Basic Microbiol 39(3):161–168

Lekha PK, Lonsane BK (1997) Production and application of tannin acyl hydrolase: state of art. Adv Appl Microbiol 44:215–260

Lewis JA, Starkey RL (1969) Decomposition of plant tannins by some soil microorganisms. Soil Sci 107:235–241

Manjit, Yadav A, Aggarwal NK, Kumar K, Kumar A (2008) Tannase production by Aspergillus fumigatus MA under solid-state fermentation. World J Microbiol Biotechnol 24:3023–3030

Mondal KC, Pati BR (2000) Studies on the extracellular tannase from newly isolated Bacillus licheniformis KBR 6. J Basic Microbiol 40:223–232

Mondal KC, Banerjee R, Pati BR (2000) Tannase production by Bacillus licheniformis. Biotechnol Lett 20:767–769

Mondal KC, Banerjee D, Jana M, Pati BR (2001a) Colorimetric assay for determination of Tannin Acyl Hydrolase (E.C. 3.1.1.20) activity. Anal Biochem 295:168–171

Mondal KC, Banerjee D, Banerjee R, Pati BR (2001b) Production and characterization of tannase from Bacillus cereus KBR9. J Gen Appl Microbiol 47:263–267

Nishitani Y, Sasaki E, Fujisawa T, Osawa R (2004) Genotypic Analyses of Lactobacilli with a range of tannase activities isolated from human feces and fermented foods. Syst Appl Microbiol 27:109–117

O’Donovan L, Brooker JD (2001) Effect of hydrolysable and condensed tannins on growth, morphology and metabolism of Streptococcus gallolyticus (S. caprinus) and S. bovis. Microbiology 147:1025–1033

Osawa R, Kuroiso K, Goto S, Shimizu A (2000) Isolation of tannin-degrading Lactobacilli from humans and fermented foods. Appl Environ Microbiol 66:3093–3097

Ramirez-Coronel A, Viniegra-Gonzalez G, Darvill A, Augur C (2003) Characterization of a bifunctional tannase from Aspergillus niger. Microbiology 149(10):2941–2946

Rodriguez H, de Las Rivas B, Gomez-Cordoves C, Munoz R (2008) Characterization of tannase activity in cell-free extracts of Lactobacillus plantarum CECT 748T. Int J Food Microbiol 121(1):92–98

Sabu A, Augur C, Swati C, Pandey A (2006) Tannase production by Lactobacillus sp. ASR-S1 under solid-state fermentation. Proc Biochem 41:575–580

Van De Lagemaat J, Pyle DL (2005) Modeling the uptake and growth kinetics of Penicillium glabrum in a tannic acid-containing solid-state fermentation for tannase production. Proc Biochem 40(5):1773–1782

Acknowledgments

The senior research fellowship under Rajiv Gandhi National Fellowship scheme (University Grant Commission) sponsored by the Ministry of Social Justice & Empowerment and Ministry of Tribal Affairs, Govt. of India to the first author is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Selwal, M.K., Yadav, A., Selwal, K.K. et al. Optimization of cultural conditions for tannase production by Pseudomonas aeruginosa IIIB 8914 under submerged fermentation. World J Microbiol Biotechnol 26, 599–605 (2010). https://doi.org/10.1007/s11274-009-0209-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-009-0209-x