Abstract

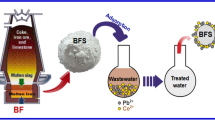

Steel slag is a major industrial waste in steel industries, and its dissolution behavior in water needs to be characterized in the larger context of its potential use as an agent for sequestering CO2. For this purpose, a small closed system batch reactor was used to conduct the dissolution of steel slags in an aqueous medium under various dissolution conditions. In this study, two different types of steel slags were procured from steel plants in India, having diverse structural features, mineralogical compositions, and particle sizes. The experiment was performed at different temperatures for 240 h of dissolution at atmospheric pressure. The dissolution rates of major and minor slag elements were quantified through liquid-phase elemental analysis using an inductively coupled plasma atomic emission spectroscopy at different time intervals. Advanced analytical techniques such as field emission gun-scanning electron microscope, energy-dispersive X-ray, BET, and XRD were also used to analyze mineralogical and structural changes in the slag particles. High dissolution of slags was observed irrespective of the particle size distribution, which suggests high carbonation potential. Concentrations of toxic heavy metals in the leachate were far below maximum acceptable limits. Thus, the present study investigates the dissolution behavior of different mineral ions of steel slag in aqueous media in light of its potential application in CO2 sequestration.

Similar content being viewed by others

References

Baciocchi R, Costa G, Polettini A et al (2009) Comparison of different reaction routes for carbonation of APC residues. Energy Procedia 1:4851–4858. doi:10.1016/j.egypro.2009.02.313

Bao W, Li H, Yi Z (2010) Selective leaching of steelmaking slag for indirect CO2 mineral sequestration. Ind Eng Chem Res 49:2055–2063. doi:10.1021/ie801850s

Bertos MF, Li X, Simons SJR et al (2004) Investigation of accelerated carbonation for the stabilisation of MSW incinerator ashes and the sequestration of CO2. Green Chem 6:428–436. doi:10.1039/b401872a

Bobicki ER, Liu Q, Xu Z, Zeng H (2012) Carbon capture and storage using alkaline industrial wastes. Prog Energy Combust Sci 38:302–320. doi:10.1016/j.pecs.2011.11.002

Bonenfant D, Kharoune L, Sauve S et al (2008) CO2 sequestration potential of steel slags at ambient pressure and temperature. Ind Eng Chem Res 47:7610–7616. doi:10.1021/ie701721j

Bonfils B, Julcour-Lebigue C, Guyot F et al (2012) Comprehensive analysis of direct aqueous mineral carbonation using dissolution enhancing organic additives. Int J Greenh Gas Control 9:334–346. doi:10.1016/j.ijggc.2012.05.009

Butt DP, Lackner KS, Wendt CH et al (1996) Kinetics of thermal dehydroxylation and carbonation of magnesium hydroxide. J Am Ceram Soc 79:1892–1898. doi:10.1111/j.1151-2916.1996.tb08010.x

Chang EE, Chiu AC, Pan SY et al (2013) Carbonation of basic oxygen furnace slag with metalworking wastewater in a slurry reactor. Int J Greenh Gas Control 12:382–389. doi:10.1016/j.ijggc.2012.11.026

Costa G, Polettini A, Pomi R, Stramazzo A (2016) Leaching modelling of slurry-phase carbonated steel slag. J Hazard Mater 302:415–425. doi:10.1016/j.jhazmat.2015.10.005

CPCB (2006) Assessment of utilisation of industrial solid wastes in cement manufacturing. Central Pollution Control Board, Ministry of Environment & Forests, Govt. of India

Daval D, Martinez I, Corvisier J et al (2009) Carbonation of Ca-bearing silicates, the case of wollastonite: experimental investigations and kinetic modeling. Chem Geol 262:262–277. doi:10.1016/j.chemgeo.2009.01.022

De Windt L, Chaurand P, Rose J (2011) Kinetics of steel slag leaching: batch tests and modeling. Waste Manag 31:225–235. doi:10.1016/j.wasman.2010.05.018

Diener S, Andreas L, Herrmann I et al (2010) Accelerated carbonation of steel slags in a landfill cover construction. Waste Manag 30:132–139. doi:10.1016/j.wasman.2009.08.007

Eloneva S, Said A, Fogelholm CJ, Zevenhoven R (2012) Preliminary assessment of a method utilizing carbon dioxide and steelmaking slags to produce precipitated calcium carbonate. Appl Energy 90:329–334. doi:10.1016/j.apenergy.2011.05.045

Ghacham AB, Pasquier LC, Cecchi E et al (2016) CO2 sequestration by mineral carbonation of steel slags under ambient temperature: parameters influence and optimization. Environ Sci Pollut Res. doi:10.1007/s11356-016-6926-4

Gunning PJ, Hills CD, Carey PJ (2010) Accelerated carbonation treatment of industrial wastes. Waste Manag 30:1081–1090. doi:10.1016/j.wasman.2010.01.005

Hong KJ, Tokunaga S (2000) Extraction of heavy metals from MSW incinerator fly ashes by chelating agents. J Hazard Mater 41:57–73. doi:10.1016/S0304-3894(00)00171-0

Huijgen WJJ, Comans RNJ (2005) Mineral CO2 sequestration by carbonation of industrial residues. Energy Research Centre of the Netherlands (ECN). Petten, The Netherlands

Huijgen WJJ, Comans RNJ (2003) Carbon dioxide sequestration by mineral carbonation, literature review. Energy Research Centre of the Netherlands (ECN). Petten, The Netherlands

Huijgen WJJ, Witkamp GJ, Comans RNJ (2006) Mechanisms of aqueous wollastonite carbonation as a possible CO2 sequestration process. Chem Eng Sci 61:4242–4251. doi:10.1016/j.ces.2006.01.048

Huijgen WJJ, Witkamp G-J, Comans RNJ (2005) Mineral CO2 sequestration by steel slag carbonation. Environ Sci Technol 39:9676–9682. doi:10.1021/es050795f

Huntzinger DN, Eatmon TD (2009) A life-cycle assessment of Portland cement manufacturing: comparing the traditional process with alternative technologies. J Clean Prod 17:668–675. doi:10.1016/j.jclepro.2008.04.007

IPCC (2005) IPCC special report on carbon dioxide capture and storage. Cambridge University Press, Cambridge

Johnson CA, Brandenberger S, Baccini P (1995) Acid neutralizing capacity of municipal waste incinerator bottom ash. Environ Sci Technol 29:142–147. doi:10.1021/es00001a018

Kasuura H, Inoue T, Hiraoka M, Sakai S (1996) Full-scale plant study on fly ash treatment by the acid extraction process. Waste Manag 16:491–499. doi:10.1016/S0956-053X(96)00091-8

Koljonen T, Siikavirta H, Zevenhoven R, Savolainen I (2004) CO2 capture, storage and reuse potential in Finland. Energy 29:1521–1527. doi:10.1016/j.energy.2004.03.056

Lackner KS, Butt DP, Wendt CH (1997) Progress on binding CO2 in mineral substrates. Energy Convers Manag 38:S259–S264. doi:10.1016/S0196-8904(96)00279-8

Lekakh SN, Rawlins CH, Robertson DGC et al (2008) Kinetics of aqueous leaching and carbonization of steelmaking slag. Metall Mater Trans B Process Metall Mater Process Sci 39:125–134. doi:10.1007/s11663-007-9112-8

Li Z, Zhao S, Zhao X, He T (2012) Leaching characteristics of steel slag components and their application in cementitious property prediction. J Hazard Mater 199–200:448–452. doi:10.1016/j.jhazmat.2011.07.069

Morone M, Costa G, Georgakopoulos E et al (2016) Granulation–carbonation treatment of alkali activated steel slag for secondary aggregates production. Waste and Biomass Valorization. doi:10.1007/s12649-016-9781-0

O’Connor W, Dahlin D, Rush G et al (2005) Aqueous mineral carbonation, mineral availability, pretreatment, reaction parametrics, and process studies. National Energy Technology Laboratory, Office of Fossil Energy, US

O’Connor WK, Dahlin DC, Nilsen DN et al (2000) Carbon dioxide sequestration by direct mineral carbonation with carbonic acid. Proc 25th Int Tech Conf Coal Util Fuel Syst 0–15

Olajire AA (2013) A review of mineral carbonation technology in sequestration of CO2. J Pet Sci Eng 109:364–392. doi:10.1016/j.petrol.2013.03.013

Pan SY, Chang EE, Chiang PC (2012) CO2 capture by accelerated carbonation of alkaline wastes: a review on its principles and applications. Aerosol Air Qual Res 12:770–791. doi:10.4209/aaqr.2012.06.0149

Pan SY, Chiang PC, Chen YH et al (2013) Systematic approach to determination of maximum achievable capture capacity via leaching and carbonation processes for alkaline steelmaking wastes in a rotating packed bed. Environ Sci Technol 47:13677–13685. doi:10.1021/es403323x

Park AHA, Fan LS (2004) CO2 mineral sequestration: physically activated dissolution of serpentine and pH swing process. Chem Eng Sci 59:5241–5247. doi:10.1016/j.ces.2004.09.008

Proctor DM, Fehling KA, Shay EC et al (2000) Physical and chemical properties of blast furnace, basic oxygen furnace and electric arc furnace steel industry slag. Environ Sci Technol 34:1576–1582

Quina MJ, Bordado JC, Quinta-Ferreira RM (2008) Treatment and use of air pollution control residues from MSW incineration: an overview. Waste Manag 28:2097–2121. doi:10.1016/j.wasman.2007.08.030

Revathy TDR, Palanivelu K, Ramachandran A (2015) Direct mineral carbonation of steelmaking slag for CO2 sequestration at room temperature. Environ Sci Pollut Res 23:7349–7359. doi:10.1007/s11356-015-5893-5

Sahu RC, Patel RK, Ray BC (2010) Neutralization of red mud using CO2 sequestration cycle. J Hazard Mater 179:28–34. doi:10.1016/j.jhazmat.2010.02.052

Sanna A, Uibu M, Caramanna G et al (2014) A review of mineral carbonation technologies to sequester CO2. Chem Soc Rev 43:8049–8080. doi:10.1039/c4cs00035h

Santos RM, Ling D, Sarvaramini A et al (2012) Stabilization of basic oxygen furnace slag by hot-stage carbonation treatment. Chem Eng J 203:239–250. doi:10.1016/j.cej.2012.06.155

Sipilä J, Teir S, Zevenhoven R (2008) Carbon dioxide sequestration by mineral carbonation literature review update 2005–2007. Faculty of Technology, Heat Engineering Laboratory, Abo Akademi University, Finland

Sorlini S, Sanzeni A, Rondi L (2012) Reuse of steel slag in bituminous paving mixtures. J Hazard Mater 209–210:84–91. doi:10.1016/j.jhazmat.2011.12.066

Squires K, Wolf GH (2006) Carbon sequestration via aqueous olivine mineral carbonation: role of passivating layer formation. Environ Sci Technol 40:4802–4808. doi:10.1021/es0523340

Teir S (2008) Fixation of carbon dioxide by producting carbonates from minerals and steelmakingslags. Doctoral Dissertation, Department of Energy Technology, Helsinki University of Technology, Finland

Teir S, Eloneva S, Fogelholm CJ, Zevenhoven R (2007) Dissolution of steelmaking slags in acetic acid for precipitated calcium carbonate production. Energy 32:528–539. doi:10.1016/j.energy.2006.06.023

van Oss HG (2015) Iron and steel slag. U.S. Geological Survey, Mineral Commodity Summaries, US

van Zomeren A, van der Laan SR, Kobesen HBA et al (2011) Changes in mineralogical and leaching properties of converter steel slag resulting from accelerated carbonation at low CO2 pressure. Waste Manag 31:2236–2244. doi:10.1016/j.wasman.2011.05.022

Xiao LS, Wang R, Chiang PC et al (2014) Comparative life cycle assessment (LCA) of accelerated carbonation processes using steelmaking slag for CO2 fixation. Aerosol Air Qual Res 14:892–904. doi:10.4209/aaqr.2013.04.0121

Yan J, Moreno L, Neretnieks I (1997) The long-term acid neutralizing capacity of steel slag. Stud Environ Sci 71:631–640. doi:10.1016/S0166-1116(97)80246-4

Yuen YT, Sharratt PN, Jie B (2016) Carbon dioxide mineralization process design and evaluation: concepts, case studies, and considerations. Environ Sci Pollut Res 1–22. doi: 10.1007/s11356-016-6512-9

Acknowledgements

This study is partially funded by a grant from Consortium for Clean Coal Utilization, Mcdonnell Academy, St. Louis, USA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Yadav, S., Mehra, A. Dissolution of steel slags in aqueous media. Environ Sci Pollut Res 24, 16305–16315 (2017). https://doi.org/10.1007/s11356-017-9036-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9036-z