Abstract

Due to the high increase in the consumption of building energy in the world, it is urgent to develop and use thermal insulation materials to limit the demand of energy. In this article, the possibility of producing thermal insulation plasters from common cementitious materials such as fly ash (FA), metakaolin (MK), and silica fume (SF) without employing any foaming agent or lightweight aggregate was investigated. Either cement or gypsum was used as a binder material. Eight different types of plaster based on different pozzolanic materials were investigated and compared with the traditional cement mortar plaster (TC). The compressive strength, bulk density, total porosity, thermal conductivity, and thermal resistance were measured. The results showed that it is possible to produce thermal insulation plasters based on pozzolanic materials without including foaming agent or lightweight aggregate. The obtained insulating plasters exhibited low density (888.75-1575.63 kg/m3), high porosity (39.5-57.75%), low thermal conductivity (0.30-0.48 W/mK) and suitable compressive strength. Using gypsum as a binder material was better than cement for insulation purposes. SF showed the highest insulation efficiency followed by FA and MK.

Similar content being viewed by others

Data Availability

Not applicable.

References

Abergel T, Dean B, Dulac J (2017) Towards a zero-emission, efficient, and resilient buildings and construction sector: Global Status Report 2017. UN Environment and International Energy Agency, Paris, p 22

Aditya L, Mahlia T, Rismanchi B, Ng H, Hasan M, Metselaar H, Muraza O, Aditiya H (2017) A review on insulation materials for energy conservation in buildings. Renew Sust Energ Rev 73:1352–1365

Ashrae A (1997) Handbook of Fundamentals, American Society of Heating. Refrigerating and Air Conditioning Engineers Inc, Atlanta

Balto Y, Edwin Raj R, Anne Chandra J & Vettivel S (2019) Experimental investigation of discarded additive material combination and composition to appropriate thermal insulating properties of the composite cement mortar. Eur J Environ Civil Eng 1-11.

Başpınar MS, Kahraman E (2011) Modifications in the properties of gypsum construction element via addition of expanded macroporous silica granules. Constr Build Mater 25(8):3327–3333

Bicer A (2019) Influence of tragacanth resin on the thermal and mechanical properties of fly ash-cement composites. J Adhes Sci Technol 33(10):1019–1032

Brooks AL, Shen Z, Zhou H (2020) Development of a high-temperature inorganic synthetic foam with recycled fly-ash cenospheres for thermal insulation brick manufacturing. J Clean Prod 246:118748

Ciudad A, Lacasta A, Haurie L, Formosa J, Chimenos J (2011) Improvement of passive fire protection in a gypsum panel by adding inorganic fillers: experiment and theory. Appl Therm Eng 31(17-18):3971–3978

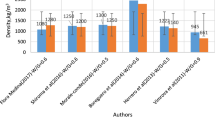

Demirboǧa R (2003) Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build 35(2):189–192

Demirboğa R (2007) Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build Environ 42(7):2467–2471

Du Y, Yang W, Ge Y, Wang S, Liu P (2021) Thermal conductivity of cement paste containing waste glass powder, metakaolin and limestone filler as supplementary cementitious material. J Clean Prod 287:125018

Duong HM, Ling NR, Thai QB, Le DK, Nguyen PT, Goh XY, Phan-Thien N (2021) A novel aerogel from thermal power plant waste for thermal and acoustic insulation applications. Waste Manag 124:1–7

Hodhod O, Rashad A, Abdel-Razek M, Ragab A (2009) Coating protection of loaded RC columns to resist elevated temperature. Fire Saf J 44(2):241–249

Hu R, Ma A, Wang Y (2018) Transient hot wire measures thermophysical properties of organic foam thermal insulation materials. Exp Thermal Fluid Sci 98:674–682

Hu X, Shi C, Li J, Wu Z (2021) Chloride migration in cement mortars with ultra-low water to binder ratio. Cem Concr Compos 118:103974

Jiang D, Lv S, Cui S, Sun S, Song X, He S, Zhang J, An P (2020) Effect of thermal insulation components on physical and mechanical properties of plant fibre composite thermal insulation mortar. J Mater Res Technol 9(6):12996–13013

Lamy-Mendes A, Pontinha ADR, Alves P, Santos P, Durães L (2021) Progress in silica aerogel-containing materials for buildings’ thermal insulation. Constr Build Mater 286:122815

Leiva C, Arenas C, Vilches L, Alonso-Fariñas B, Rodriguez-Galán M (2015) Development of fly ash boards with thermal, acoustic and fire insulation properties. Waste Manag 46:298–303

Li Q, Wei H, Zhang Y, Han L, Han S, Ding N (2020) The variations on thermal conductivity and structures of silty clay modified by waste fly ash and oil shale ash after freeze–thaw cycles. Constr Build Mater 260:119954

Liu T, Tan Z, Xu C, Chen H, Li Z (2020) Study on deep reinforcement learning techniques for building energy consumption forecasting. Energy Build 208:109675

Luo Y, Jiang Y, Feng J, Feng J (2019) Synthesis of white cement bonded porous fumed silica-based composite for thermal insulation with low thermal conductivity via a facile cast-in-place approach. Constr Build Mater 206:620–629

Mandili B, Taqi M, El Bouari A, Errouaiti M (2019) Experimental study of a new ecological building material for a thermal insulation based on waste paper and lime. Constr Build Mater 228:117097

Melo JP, Medina NF, Aguilar AS, Olivares FH (2017) Rheological and thermal properties of aerated sprayed mortar. Constr Build Mater 154:275–283

Morsy M, Alsayed S, Salloum Y (2012) Development of eco-friendly binder using metakaolin-fly ash–lime-anhydrous gypsum. Constr Build Mater 35:772–777

Morsy M, Rashad AM, Shoukry H, Mokhtar M (2019) Potential use of limestone in metakaolin-based geopolymer activated with H3PO4 for thermal insulation. Constr Build Mater 229:117088

Morsy M, Rashad AM, Shoukry H, Mokhtar M, El-Khodary S (2020) Development of lime-pozzolan green binder: the influence of anhydrous gypsum and high ambient temperature curing. J Build Eng 28:101026

Muñoz P, Morales M, Mendívil M, Juárez M, Muñoz L (2014) Using of waste pomace from winery industry to improve thermal insulation of fired clay bricks. Eco-friendly way of building construction. Constr Build Mater 71:181–187

Nejat P, Jomehzadeh F, Taheri MM, Gohari M, Majid MZA (2015) A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew Sust Energ Rev 43:843–862

Ng S, Jelle BP (2017) Incorporation of polymers into calcined clays as improved thermal insulating materials for construction. Adv Mater Sci Eng 2017:6478236

Phavongkham V, Wattanasiriwech S, Cheng T-W, Wattanasiriwech D (2020) Effects of surfactant on thermo-mechanical behavior of geopolymer foam paste made with sodium perborate foaming agent. Constr Build Mater 243:118282

Rashad AM (2013) Metakaolin as cementitious material: history, scours, production and composition–a comprehensive overview. Constr Build Mater 41:303–318

Rashad AM (2015a) A brief on high-volume Class F fly ash as cement replacement–a guide for civil engineer. Int J Sustain Built Environ 4(2):278–306

Rashad AM (2015b) An exploratory study on high-volume fly ash concrete incorporating silica fume subjected to thermal loads. J Clean Prod 87:735–744

Rashad AM (2015c) Metakaolin: fresh properties and optimum content for mechanical strength in traditional cementitious materials-a comprehensive overview. Rev Adv Mater Sci 40(1):15–44

Rashad AM (2016a) A synopsis about perlite as building material–a best practice guide for civil engineer. Constr Build Mater 121:338–353

Rashad AM (2016b) Vermiculite as a construction material–a short guide for civil engineer. Constr Build Mater 125:53–62

Rashad AM (2018) Lightweight expanded clay aggregate as a building material–an overview. Constr Build Mater 170:757–775

Rashad AM (2019a) Insulating and fire-resistant behaviour of metakaolin and fly ash geopolymer mortars. Proc Instit Civil Eng-Constr Mater 172(1):37–44

Rashad AM (2019b) A short manual on natural pumice as a lightweight aggregate. J Build Eng 25:100802

Rashad AM, Khalil MH (2013) A preliminary study of alkali-activated slag blended with silica fume under the effect of thermal loads and thermal shock cycles. Constr Build Mater 40:522–532

Rashad AM, Hassan AA, Zeedan SR (2016) An investigation on alkali-activated Egyptian metakaolin pastes blended with quartz powder subjected to elevated temperatures. Appl Clay Sci 132:366–376

Rashad AM, Ouda AS, Sadek DM (2018) Behavior of alkali-activated metakaolin pastes blended with quartz powder exposed to seawater attack. J Mater Civ Eng 30(8):04018159

Rashad AM, Khafaga SA, Gharieb M (2021) Valorization of fly ash as an additive for electric arc furnace slag geopolymer cement. Constr Build Mater 294:123570

Selvaranjan K, Navaratnam S, Gamage J, Thamboo J, Siddique R, Zhang J, Zhang G (2021) Thermal and environmental impact analysis of rice husk ash-based mortar as insulating wall plaster. Constr Build Mater 283:122744

Sivapullaiah PV, Moghal AAB (2011) Role of gypsum in the strength development of fly ashes with lime. J Mater Civ Eng 23(2):197–206

Stolz J, Boluk Y, Bindiganavile V (2019) Wood ash as a supplementary cementing material in foams for thermal and acoustic insulation. Constr Build Mater 215:104–113

Sun JY, Xu YD (2011) Study on the effect of waste gypsum on hardening paste structure and performances of lime-fly ash. (In Advanced Materials Research) Trans Tech Publ 213:31–34

Taha AS, Serry MA, El-Didamony H (1985) Hydration characteristics of metakaolin—lime—gypsum. Thermochim Acta 90:287–296

Wang H, Sun Y, Liu L, Ji R, Wang X (2018) Integrated utilization of fly ash and waste glass for synthesis of foam/dense bi-layered insulation ceramic tile. Energy Build 168:67–75

Wang Y, Shui Z, Gao X, Huang Y, Yu R, Ling G (2019) Chloride binding behaviors of metakaolin-lime hydrated blends: influence of gypsum and atmospheric carbonation. Constr Build Mater 201:380–390

Yang L, Peng Z, Huang Y, Wang L, Zheng L, Rao M, Li G, Jiang T (2021) Co-utilization of ferronickel slag and fly ash cenosphere for production of superior thermal insulation materials. Ceram Int 47(7):10019–10026

Zhang Y, Sun Q, Yang X (2018) Changes in color and thermal properties of fly ash cement mortar after heat treatment. Constr Build Mater 165:72–81

Zhang J, Pan G, Zheng X, Chen C (2021) Preparation and characterization of ultra-lightweight fly ash-based cement foams incorporating ethylene-vinyl acetate emulsion and waste-derived CSH seeds. Constr Build Mater 274:122027

Zhu M, Ji R, Li Z, Wang H, Liu L, Zhang Z (2016) Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr Build Mater 112:398–405

Author information

Authors and Affiliations

Contributions

Alaa M. Rashad: Experimental design, methodology, investigation, conceptualization, supervision, analysis, writing (original draft), and writing (review and editing).

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rashad, A.M. Possibility of producing thermal insulation materials from cementitious materials without foaming agent or lightweight aggregate. Environ Sci Pollut Res 29, 3784–3793 (2022). https://doi.org/10.1007/s11356-021-15873-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-15873-4