Abstract

Purpose

Cradle-to-gate life cycle inventories (LCIs) for the production of a series of common surfactants used in European detergents and personal care products have been voluntarily compiled by 14 major companies collaborating within ERASM (www.erasm.org). The study builds on a similar project executed by CEFIC-Franklin (1994) and summarised by Stalmans et al. (Tenside Surf Det 32:84–109, 1995). The data are targeted as an industry-agreed and representative market average for surfactants in Europe for the reference year 2011. The purpose of this paper is to describe how these dataset were generated, to provide some summary results and interpretation, and to indicate where the full datasets and additional technical documentation can be found.

Methods

The methodology followed was an attributional life cycle assessment (LCA) approach, compliant with LCA standards ISO 14040 (2006), ISO 14044 (2006), and ILCD entry level (2010). For each major unit process in the production of surfactants and precursors, a minimum of three companies (a ‘trio’) was identified. When no industry-specific data were available, either literature or recent and reliable process data were used. For worldwide traded precursor materials like palm oil, palm kernel oil, and coconut oil, an extensive literature-based LCI study was performed. Two independent external reviewers supported the project from the beginning through completion. In addition, the oil palm and coconut- and tallow-based renewable precursors were reviewed by a third independent expert.

Results and discussion

In the study, a good level of representativeness was achieved with 70 primary data collections in 12 companies. To illustrate the outcome of the work, two indicators/impacts were calculated and reported, i.e. primary energy demand (PED) and global warming potential (GWP). The LCIs allow the calculation of additional impact categories, but these were not analysed within the scope of this project.

The PED for most of the surfactants and their precursors is in the range of 52 to 77 GJ/tonne. Exceptions are the production of cocamide diethanolamine (CDEA) and C16–C18 triethanolamine esterquat (TEA-quat) with a PED of around 40 GJ/tonne, and 3-dimethylaminopropylamine (DMAPA) around 108 GJ/tonne. Petrochemical precursors show an intensive but established and optimised supply chain. Where comparison is possible, their PED does not differ much from the earlier CEFIC-Franklin (1994) data. There are indications that PED for surfactant production has decreased slightly over the last 20 years due to energy efficiency measures.

The GWP for the reportable precursors ranges from − 1989 kg CO2e/tonne for Coconut Oil Methyl Ester to 4894 kg CO2e/tonne for DMAPA. For the final surfactants, the range is from − 887 kg CO2e/tonne for CDEA to 2674 kg CO2e/tonne for C12–C15 AE3. There is a significant difference between the cradle-to-gate GWP of the renewable precursors palm oil/palm kernel oil (PO/PKO) and coconut oil (CNO). The CNO products have a calculated net negative cradle-to-gate GWP, while the PO/PKO products have a net positive GWP. The latter is mainly attributable to the land use change (LUC) factor and plantings on peat soils. Beef tallow also has a net negative GWP of − 1529 kg CO2e/tonne. This value is very sensitive to the allocation choice.

Conclusions

The industry average LCI data and linked metadata are made publically available as aggregated datasets in three different formats (EcoSpold v.2, ILCD, and GaBi 6 2013). They benefit from increased methodological standardisation and a more complete background process data versus the CEFIC-Franklin (1994) study, but are therefore only partially comparable. It is recommended that the surfactant LCI data are used and interpreted in a finished product cradle-to-grave context.

Similar content being viewed by others

1 Introduction

1.1 Study objectives and motivation

The Surfactant Life Cycle & Ecofootprinting (SLE) project was commissioned by ERASMFootnote 1 with the objective to update or establish cradle-to-gate life cycle inventories (LCIs) for a series of commercially important surfactants and their precursors/intermediates, based on current surfactant production technology (reference year 2011) and consistent high-quality background data. The new LCI data are intended to support the increasing use of life cycle assessment (LCA) in industry as well as in various policy initiatives.

The SLE project builds upon an earlier, pioneering LCI project which will be referenced further as the CEFIC-Franklin (1994) study. The full results and analysis of this study were published in two special issues of the journal Tenside Surfactants Detergents (2/95 and 5/95) under the heading of ‘European Life-Cycle Inventory for Detergent Surfactants Production’. The technical data reported therein refer to reference year 1992. A summary of the work was provided by Stalmans et al. (1995). Data from the CEFIC-Franklin (1994) study have been used extensively in industry LCA projects on cleaning products since 1995 and have also been adopted by several public Life Cycle Inventory databases (e.g. ecoinvent, GaBi 2013).

Societal, regulatory, and commercial interests in the issue of climate change and carbon footprinting have significantly increased in recent years. In addition, multi-indicator ‘Product Environmental Footprinting’ (PEF) calculation and communication initiatives for fast-moving consumer goods (FMCG) are being developed. The European detergent and surfactant industries are engaged in testing schemes such as the pilot project on Product Environmental Footprinting Category Rules (PEFCR), launched by the European Commission (PEF Guidance 2014; http://ec.europa.eu/environment/eussd/smgp/product_footprint.htm). Recognizing that the LCI data for the production of surfactants were getting outdated and were unlikely to meet existing stringent data quality and representativeness requirements, ERASM initiated the SLE project to ensure data continuity for the sector, as well as to cover some additional types of surfactants for which no LCI data were previously available. Fourteen major industrial companies active as surfactant producers and/or formulators have collaborated to collect unit process data from their plants, in order to produce representative LCIs for surfactant production. The project was technically led by the LCA consultant PE International (now thinkstep), who also acted as a neutral interface between the companies and ensured data handling confidentiality. Administrative and financial support was provided by ERASM, operating under CEFIC.Footnote 2 The practical feasibility and exact project scope were developed during a pilot project (ERASM SLE 2011).

1.2 Intended application and use of the data

The purpose of this paper is to present the context, approach, key results, and conclusions from the ERASM SLE project. It is not the intention to deliver with this paper full technical (process) details or the final datasets. These are made publically available via other channels (see Section 5).

The LCI datasets are released in a series of state-of-the-art data formats (i.e. ILCD, EcoSpold v2, GaBi) which can be imported into LCA software systems. The LCIs generated in this project are positioned as market-average benchmark LCI data for surfactants used on the European market for reference year 2011. The LCI calculations are compliant with the international LCA standards ISO 14040 (2006a) and ISO 14044 (2006b). In addition, the study follows the ILCD (2010) handbook and the decision context C2. The latter is used for the development of specific, average, or generic unit process or LCI datasets for use in different applications, and follows an accounting approach with no reference to any potential benefits outside the analysed system. The datasets are intended to provide a perspective on the environmental quality and impact of the production of the different surfactants. Appropriate caution and nuance is needed when comparing surfactants amongst each other, or when comparing to similar sources of data. In this study, results refer to a functional (or declared) unit of 1000 kg active substance (1 metric tonne). However, this does not imply that the different surfactants are actually used in real product systems in identical amounts, or can be freely substituted. Also, the SLE data were collected according to certain methodological principles or choices (see further), which may not be identical to other studies. This also applies to any comparison effort of the current data versus the CEFIC-Franklin (1994) work, especially since LCI and life cycle impact assessment (LCIA) methodologies have undergone a significant evolution and further standardisation.

1.3 Presentation of the results

The objective of the ERASM SLE project was to prepare surfactant LCI datasets of the best quality practically achievable. No emissions were actively excluded from the inventory, and to the knowledge of the authors, all emission flows were included. LCIA was not conducted for two main reasons: firstly, the science of the impact assessment methodology for a number of impact categories is still highly dynamic, which may cause the results to be quickly outdated; secondly, the surfactant data should preferably be used in the context of a full, cradle-to-grave, product system. For information and illustration purposes, only the total primary energy demand (PED) and global warming potential (GWP) indicators are presented in the paper. PED is shown as this was an indicator used in the original CEFIC-Franklin (1994) study. The GWP results are of interest to many stakeholders and are calculated using current methodologies. The SLE LCI datasets also contain the necessary information to calculate several other impact categories according to the user’s preferred impact method. Especially, the following impacts methods published in the handbook of LCA (Guinée et al. 2002) and known as the CML method were tested to be functional: depletion of non-renewable resources, global warming potential (climate change), eutrophication, acidification, and photochemical smog. Additionally, the LCI datasets enable an evaluation of human and ecotoxicity employing the USEtox (Rosenbaum et al. 2008) characterisation model. Other environmental indicators can be assessed with these LCIs, but results have to be treated more carefully than the above ones for the intended application. Social, economic, and other themes like noise, odour, and biodiversity impacts were not considered.

1.4 Peer review

ERASM, as an organisation, aims to release high-quality scientific information about surfactants and has no direct commercial interest in the results. The ERASM SLE study meets the ISO requirements for critical review. It was opted to work with an accompanying critical review process allowing the reviewers to influence the choices and methodologies along the project, thereby minimizing the need for rework or concerns at the final stages. The independent experts performing the review process were Prof. Dr. Walter Kloepffer (LCA Consultant & Review); Dr. Yannick Leguern and Dr. Charlotte Petiot (Bio-IS by Deloitte). They accompanied the project from start to finish. In addition, Dr. Jannick Schmidt (Aarhus University and 2.-0 Consultants) was engaged as expert to specifically review the work on the renewable precursors palm oil, palm kernel oil, and coconut oil, in addition to the land use change (LUC) methodologies.

2 Methodology

2.1 Goal and scope

The main goals of the study were to update the existing LCI datasets (CEFIC-Franklin 1994) for the production of major surfactants and their main precursors/intermediates, as well as to generate new inventories for a selection of market-relevant surfactants not yet covered. A total of 32 LCIs (15 surfactants and 17 precursors) were generated as depicted in (Fig. 1). Where possible, a time-trend analysis was performed in order to assess process efficiency progress in industry. In addition, individual companies generated LCI datasets for their own production sites based on their data submitted to the consultant.

Overview of substances included in the study. The grey boxes indicate the most relevant substances with data taken from the GaBi Professional database 6.115, service pack 22. The substances in the red boxes are based on data of a literature research covering recent production technology. These LCI models combine GaBi data as background information and literature data in the foreground system. For the substances in the green boxes, an industry (primary) data collection was done

Although for each LCI the typical final step of a full environmental impact assessment is not performed, the requirements of the usual LCIA methodologies were taken into account during data collection and in the LCI preparation. In doing so, each user has the flexibility to choose an appropriate impact assessment methodology to evaluate their results when making use of the LCIs generated in this project.

2.2 Functional unit and substances covered

The functional unit is a ‘quantified performance of a product system for use as a reference unit’ in a life cycle assessment study (ISO 14040, 2006a; ISO 14044, 2006b). For application-unspecific materials as well as for multiple use machines, the number of possible applications and functional units are often extremely large to virtually indefinite. This is the case for the current study. In agreement with the project consortium and following the reference unit used in the CEFIC-Franklin 1994 study, the term ‘declared unit’ is used, and the reference flow fitting the purposes of this study was fixed as one thousand kilogramme (1000 kg) of surfactant active ingredient, or chosen precursors and intermediates. Within the study, the declared unit of each product includes all relevant parts of their cradle-to-gate system. Table 1 provides a list of chemicals considered in this project, each of them using the above declared unit.

Most surfactants and precursors are delivered at the factory gate as aqueous solutions, i.e. x% active ingredient matter dissolved in water. However, the declared unit is defined on the basis of active matter for all surfactants, precursors, and intermediates. To equalise the different concentration levels resulting from company-specific production figures, the study applied a concentration scheme with the goal to present every LCI for 1000 kg at 100% active ingredient level (Fig. 2). According to the example shown below, the reference flow would be 1000 kg surfactant active ingredient matter (or for example 1250 kg average product with a concentration of 80%).

2.3 System boundaries and cut-off criteria

LCI datasets comprise input and output flows of the product system. Facilitating the cradle-to-gate approach, all processes starting from the extraction of natural resources (cradle) to the manufacturing of the product are in the final dataset. Detailed system boundaries were established for each substance covered.

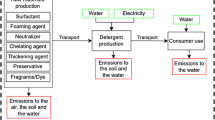

Figure 3 shows how the system boundaries as a cradle-to-gate system are described, with C12–C14 AE7 as example. The foreground system (gate-to-gate) data can be either collected in the different single operations, or as one integrated ‘black-box’ process. In the latter case, the collected data include more than one single operation unit. In this project, the descriptions of the production processes are generic and represent an industry average.

The study includes upstream production of primary and secondary intermediates and processing of these materials and energies that make up the production of the stated declared unit (manufacture of surfactants), as well as transport of materials to surfactant production. Energy mixes are included, and their conversion efficiencies depend on the technology used. Whenever a co-product occurs, appropriate treatment was applied (e.g. allocation) and documented, such that only one output flow—the desired product—is coming out of the system.

The study intends to reflect European market mixes. Hence, a realistic depiction of the surfactants industry of 2011 is modelled by using specific supply chain models and region-specific background data like electricity grid mixes, thermal energy supply, transports, water supply, and waste treatment.

The cut-off criteria for the study are based on other similar industry association led LCI studies (Plastics Europe 2011). Materials, energy, and emissions data are included as follows: include all material inputs that have a cumulative total of at least 98% of the total mass inputs to the unit process; include all material inputs that have a cumulative total of at least 98% of the total energy inputs to the unit process; and include any material, no matter how small the mass or energy contribution, that has significant environmental effects in its extraction, manufacture, use, or disposal, is highly toxic, dangerous for the environment, or is classified as hazardous waste with environmental significance. The sum of the excluded material flows must not exceed 5% of mass, energy, or environmental relevance.

2.4 Methodological differences between the CEFIC-Franklin 1994 and the ERASM SLE 2014 study

The similarities and differences between the CEFIC-Franklin (1994) and the current ERASM SLE (2014) study are listed in Table 2.

Although there are many similarities between this study and the 1994 study, especially in the system scope and the functional unit, there are also some differences. Many methodological aspects of LCA were in their initial development stages in the early 1990s but have significantly evolved and have been standardised over recent years. For example, aspects such as LUC—including e.g. peat oxidation, relevant to palm oil (PO) and palm kernel oil (PKO), and to a lesser extent to coconut oil (CNO)—and biogenic carbon storage and emission are now addressed in detail within this study. The calculation of direct land use change (dLUC) emissions by identification of land cover (previous and current use) along with soil type was based on geospatial techniques. The framework of the dLUC calculations aligns with ISO standards 14044 and 14040 (2006) as well as the greenhouse gas (GHG) Protocol (2011). The detailed calculation approach for GHG emissions related to direct land use change and peat oxidation is presented in Liedke et al. (2017). The calculation of indirect land use change (iLUC) was not included within this project.

Additionally, new methodologies were incorporated within existing LCA impact categories, e.g. USEtox being proposed now as a consensus model for human and ecotoxicity impacts (Rosenbaum et al. 2008).

2.5 Co-product treatment, allocation, and sensitivity analysis

Allocation plays an important role if there is more than one product resulting from one process step. Allocation is defined in ISO 14044: 2006 as ‘partitioning the input or output flows of a process or a product system between the product system under study and one or more other product systems’. This is also valid for surfactants production, where the type of by-products varies significantly in terms of mass in relation to the product, economic value, and quality as marketable product. Hence, according to ISO 14044, allocation should be based on specific properties along with the function of product and by-product(s). For the ERASM SLE study, a general allocation approach for all surfactants was found inappropriate, and various allocation methods were tested and applied individually for each production system to reflect as much as possible industry reality. Rebitzer et al. (2004), Russel et al. (2005), and Curran (2007) provide a more detailed analysis on the issue of allocation in LCA.

Allocation was applied to fore- and background systems within the study. Three allocation approaches were used in the context of background systems, i.e. mass allocation, economic allocation, or allocation by energy. Additionally, mass allocation and economic allocation were used for foreground systems. Where possible and reasonable, mass allocation was preferred (see further).

Changes to the results which would occur if another allocation type was applied in the foreground system were covered via a sensitivity analysis. This was done by comparing alternative scenarios (see Section 3.5). Mass allocation was applied if a mass ratio is fixed by processing or stoichiometry, and the price relation of product and co-product reflects the mass ratio up to ± 3%. In some cases, the price structure of product and co-products shows a very different picture from the mass structure, e.g. for ethanolamines and beef tallow. For these products, economic (price) allocation was applied, which assumes that the demand of the described substances is sufficiently stable, and no major change in demand is expected in the near future.

2.6 Data handling, confidentiality, and quality

The primary data collection phase included more than 60 production lines. A web-based tool provided by PE International supported the data collection process. A technical flow chart was set up for each production technology to ensure a sufficient process understanding for the data collection. In this step, particular focus was given to ensuring a similar level of detail, e.g. number of unit processes for a precursor or surfactant. Based on the flow charts, data questionnaires were set up in a SoFi-based tool (SoFi Software 2007-2016). This is a web-based software platform that allows users to enter data by using their standard web browser and to review or validate their data. All participating users followed the same standards and guidance, to achieve the most consistent data. Following the data entry, the LCA practitioner inspected the entered information regarding mass and energy balance, emissions stoichiometry, yields, energy efficiency, co-products, recovered substances or energy, and wastes.

Special attention was required to meet the confidentiality requirements of all participating companies as well as industry competition rules. So-called ‘trios’ were created for every precursor and product, i.e. at least three companies were required to share relevant process data. In some cases, primary data for certain precursors were available from less than three companies. In these cases, the LCI data were used within the surfactants LCI but were not published. The data collection aimed to set up company-specific production pathways taking into account relevant technologies, individual supply chain paths, and region-specific energy supply (e.g. grid mixes) and thermal energy supply. Each production pathway, composed of precursor and surfactant unit processes, was aggregated vertically to reflect the individual company-specific reality. The vertical aggregation of production pathways forms company-specific LCIs. These LCIs were averaged by using name-plate production capacities provided confidentially by each study participant. This aggregation and averaging method is in line with the UNEP ‘Shonan guidance principles’ (UNEP 2011).

It is recognised that the delivery of aggregated LCIs, like in this study, has positive and negative aspects. The SLE project was commissioned by Industry aiming to present agreed results, allowing a common understanding of the environmental performance of surfactants and their precursors. In this context, a deeper analysis of various production technologies and the possibility to vary regional boundaries, i.e. exchanging country-specific electricity grid mixes or steam supply, was not provided.

When no industry-specific data were available, either literature or recent and reliable process data were used. The latter were mainly derived from GaBi database. More detailed references to these process LCIs are presented in the Electronic Supplementary Material.

The above procedure describes the study approach to develop industry-based, averaged LCI data. Hence, the data is to be understood as the best estimate of the EU-marketed surfactants in 2011. The authors recommend applying the ERASM LCIs whenever no specific surfactant or precursor sourcing information is available, or in case the LCA study is best served by generic/average data. The SLE life cycle inventories based on cradle-to-gate studies can be used in a LCA covering the entire product life cycle by providing information for the production stage. However, if the LCIs were to be used in a comparative assertion between surfactants, a critical review according to the panel method (minimum three critical reviewers including the chair) is recommended by ISO.

After completion of the data collection phase, the overall data quality was assessed using semi-quantitative data quality indicators according to the PEF Guide (2014). The PEF Guide defines the following data quality indicators (DQIs): technological representativeness, geographical representativeness, temporal representativeness, completeness, precision (parameter for uncertainty), and methodological appropriateness and consistency. More information on data quality in this study is provided in the Electronic Supplementary Material. The results indicated that the data were the best available and were regarded by PE International as well as by the reviewers as sufficient for the intended use (see Electronic Supplementary Material to this paper).

2.7 Technological, temporal, and geographic representativeness

Production data were collected as 12-month averages representing the reference year 2011. This approach intends to compensate for seasonal influences on the production data. Background data have reference years from 2011 and 2009 for electricity and thermal energy generation. These datasets are considered to be representative until substantial technological changes (e.g. new and innovative processes) occur in the production chain, or in the background systems. Sector organisations AISE and CESIO confirm a technological and market representativeness of at least 60% for the considered surfactants and precursors, except for C12–C14 alkyl sulphate, sodium salt (oleo) with > 50% technological representativeness for surfactants marketed in EU-28. A representativeness statement is provided in the metadata of each electronic LCI dataset. The results of the study are intended to be applicable within the European Union (i.e. for surfactant-containing products marketed in Europe). More details on the representativeness are presented in the Electronic Supplementary Material.

3 Results and discussion

3.1 Short overview of processes and inventories for four classes of surfactants

For each surfactant, a short description of the production process and data sources is provided. More detailed information about the processes and inventories is made available by ERASM in Environmental Fact Sheets for each individual surfactant (see Section 5 ‘Access to the data’).

3.1.1 Anionic surfactants

-

Linear alkylbenzene sulphonic acid (HLAS): HLAS is usually consumed in the form of the sodium salt as an anionic surfactant; minor quantities of other derivatives (e.g. ammonium salt) are also used. The neutralisation step was not considered in this study as the acid form is mainly sold, and the neutralisation step is generally performed at the customer’s plant. HLAS used in Europe is a mixture of different homologues (C10–C13 alkyl chains) and is produced by catalytic alkylation of benzene and subsequent sulphonation of the formed linear alkyl benzene (LAB) (Berna et al. 1995; Kocal et al. 2001). Two different processes are used to produce LAB: the hydrogen fluoride (HF) and the solid catalyst process, commercially known as the DETAL™ process.

-

In this study, primary production data for HLAS from five different suppliers across Europe were used, and for the precursor LAB from two different European suppliers.

-

Sodium salts of alkyl sulphate (AS): Sodium alkyl sulphates are amongst the oldest oleochemical surfactants produced (since 1930) and are widely used. The chain length of the alcohol determines the application area. Two main types of AS were considered in this study: one with a chain length of C16–18 derived from tallow and/or palm oil, and another type represented here with a chain length of C12–C14. For the production of C12–C14 alcohols, lauric oil feedstocks such as CNO and PKO are used. The use of these oils varies between manufacturing sites and also fluctuates in time based on market availability and price. The refined triglycerides are hydrolysed to yield fatty acids or are further transesterified with lower alcohols to yield fatty acid esters. Refined fatty acid methyl esters are used to generate fatty alcohol by hydrogenation (Ullmann 2010). The C12–C14 fatty alcohol is then esterified with sulphur trioxide gas to yield a sulphate.

-

Primary production data are from three different suppliers (in EU and Asia) representing the imported and produced C12–C14 AS in Europe.

-

Sodium salts of alcohol ethoxy sulphates (AES): Alcohol ethoxy sulphates, also known as alcohol ether sulphates, are derived from petro- or oleochemical alcohols. Four steps are involved in the manufacture of AES: alcohol production, ethoxylation, sulphation, and neutralisation. They generally contain 1–4 ethylene oxide units (Hirsinger and Schick 1995). Sodium salts of AES are by far the most commonly used grades. The fatty alcohol represented here is either produced from petrochemical feedstock via the oxo process (C12–C13), or based on vegetable lauric oils (C12–C14). Here the, production of the most common product, the sodium salt (Thomas 1995), is considered.

Primary production data for C12–C13 fatty alcohol production is from three different suppliers in three European countries, and for ethylene oxide production also from three different suppliers in three European countries. Primary production data for AES production is from five different suppliers based in Asia and Europe, representing the imported and locally produced AES.

-

Sodium cumene sulphonate: Sodium cumene sulphonates act as hydrotropes to modify solubilities, viscosities, and other properties of surfactants and surfactant formulations. It is produced by the sulphonation of cumene followed by neutralisation with sodium hydroxide. The sulphonation step involves the use of oleum, a solution of SO3 in sulphuric acid. The generated aromatic sulphonic acid can be converted to its respective salt by neutralisation with sodium hydroxide (Arpe 2010).

Primary production data for sodium cumene sulphonate production is from three different suppliers in Europe. The LCI data for cumene come from GaBi databases.

3.1.2 Non-ionic surfactants

-

Alcohol ethoxylates (C12–C15 AE3; C12–C15 AE7; C12–C14 AE3; C12–C14 AE7): The alcohol ethoxylates with three to seven ethylene oxide units are produced by the reaction of C12–C14 fatty alcohols (oleo) or C12–C15 fatty alcohols (petro) with ethylene oxide. The addition of ethylene oxide to the fatty alcohols leads to a distribution of homologue polyethylene glycol ether groups. The ethoxylation reaction for detergent range alcohol ethoxylates is usually catalysed by alkaline catalysts such as potassium hydroxide. The intermediate ethylene oxide is industrially produced by direct oxidation of ethylene in the presence of a silver catalyst (Franke et al. 1995; Schul et al. 1995).

Primary production data for alcohol ethoxylates production is from three different suppliers in Europe

-

Alcohol ethoxylates (C16–C18 AE ≥ 20): The C16–C18 alcohol ethoxylate with more than 20 ethylene oxide units is produced by the reaction of C16–C18 fatty alcohols from natural sources, preferably PO and tallow (TA), with ethylene oxide. The addition of ethylene oxide to the fatty alcohol leads to a distribution of homologue polyethylene glycol ether groups. The ethoxylation reaction for detergent range alcohol ethoxylates is usually catalysed by alkaline catalysts, e.g. potassium hydroxide (Ullmann 2010).

Primary production data for C16–C18 AE ≥ 20 production is from four different suppliers in Europe. The modelled data for C16–C18 alcohol production in Europe is based on secondary data from literature and process calculations, as an industry data collection was not possible in Europe. C16–C18 alcohol is based on the C16–C18 fractions of palm oil and tallow. The processing of the renewable oils to C16–C18 alcohol was modelled according to technology descriptions available from patents (EP0370273 A1 1990) and literature (Ullmann 2010) combined with chemical processing calculations made by PE International experts.

-

Cocamide diethanolamine (CDEA): Cocamide diethanolamine is an additive used as a refatting agent or to stabilise and enhance foaming properties. This substance is manufactured by the condensation reaction of lauric oils (CNO of PKO) with diethanolamine (DEA). An allocation by price for 1 kg of the desired product has been implemented in the model.

Primary production data for cocamide diethanolamine production is from three different suppliers in Europe. The LCI data for the production of the precursor diethanolamine is based on a literature research covering recent production technology. Applied background LCI data have reference years between 2008 and 2010 for electricity and thermal energy processes, respectively.

-

C12–C14 Amine Oxide (C12–C14 AO): Lauryldimethylamine oxide in a neutral aqueous solution is regarded as a non-ionic surfactant which is widely used as a constituent of manual dishwashing detergents, shampoos, and soaps. Amine oxides are produced by the reaction of tertiary amines such as alkyldimethylamine with hydrogen peroxide in a two-phase system containing a large volume of water yielding dilute products typically containing 35% active (Zoller 2008). For the production of the precursor hydrogen peroxide (H2O2), the anthraquinone process is used for more than 95% of the worldwide production.

Primary production data for amine oxide production is from four different suppliers in Europe in three different countries. The LCI for hydrogen peroxide is derived from GaBi Databases and covers European conditions. The data for H2O2 production refer to primary data from industry covering recent production technology.

3.1.3 Cationic surfactants

-

C16–C18 Triethanolamine esterquats (C16–C18 TEA-quat): C16–C18 Triethanolamine esterquat is a cationic surfactant that belongs to the class of surface active quaternary ammonium compounds used for the formulation of fabric softeners. Quaternized triethanolamine fatty acid esters are obtained by reacting triethanolamine with fatty alcohols, fatty alcohol esters or oils, and subsequent quaternization of the resulting triethanolamine fatty acid esters. The fatty acid used here is obtained from tallow. Dimethyl sulphate (DMS) is the quaternizing agent (Zoller 2008). The product is a mixture of quaternized mono-, di-, and tri-esters of triethanolamine and unconverted triethanolamine, which corresponds to the so-called quaternized triethanolamine di(tallow)fatty acid ester. The intermediate dimethyl sulphate is industrially produced by the reaction of gaseous dimethyl ether and liquid sulphur trioxide in stoichiometric quantities (Ullmann 2010).

Primary production data for triethanolamine esterquat (TEA-quat) production is from four different suppliers in Europe in three different countries. The LCI for hydrogen peroxide is derived from GaBi Databases which refer to primary data from industry covering recent production technology for European conditions. The precursor dimethyl ether was modelled by literature information out of a patent (US 6740783 B1 2004).

3.1.4 Amphoteric surfactants

-

C8–C18 alkyl amidopropyl betaine (CAPB): alkyl amidopropyl betaine is an amphoteric surfactant and the most common of the betaine types. In the production of alkyl amidopropyl betaine, two main steps are involved: formation of the fatty acid amide and carboxymethylation of the amide. For CAPB, which is represented here, the first step is the reaction of 3-dimethylaminopropylamine (DMAPA) with either fatty acids, fatty acid methyl esters, or directly with natural fats (fatty acid glycerin esters) (Zoller 2008).

The intermediate DMAPA is commercially produced via the reaction between dimethylamine and acrylonitrile to produce dimethylaminopropionitrile (DMAPN). Subsequent hydrogenation of DMAPN yields a crude reaction mixture that contains the desired DMAPA (Ernst 2012).

Chloroacetic acid is produced by the catalysed chlorination of acetic acid with chlorine (Ullmann 2010). An allocation by mass for 1 kg of the desired product chloroacetic acid has been implemented in the model.

Primary production data for alkyl amidopropyl betaine production is from three different suppliers in three countries in Europe. As primary data from industry for the intermediates DMAPA and chloroacetic acid were unavailable, the processes were modelled by secondary data. The LCIs for the intermediates are part of GaBi databases and cover European conditions.

-

Sodium cocoamphoacetate (SCA): The synthesis of amphoacetates and amphodiacetates consists of two distinct steps: synthesis of the hydroxyethylimidazoline and carboxymethylation of the imidazoline with sodium monochloroacetate (SMCA). In the first step, the fatty acid ester (based on CNO and/or PKO) is condensed with aminoethylethanolamine (AEEA) at an elevated temperature and reduced pressure. The second stage of the process is the reaction of the imidazoline with caustic soda and monochloroacetic acid (Zoller 2008).

The intermediate product AEEA is industrially produced by the process of the continuously hydrogenative amination of monoethylene glycol (Van Cauwenberge et al. 2009). An allocation by mass for 1 kg of the desired product AEEA has been implemented in the model.

Primary production data for sodium cocoamphoacetate production is from three different suppliers in three countries in Europe. The LCI data for production of AEEA refer to literature research covering recent production technology.

3.1.5 Primary energy demand and global warming potential results

The study represents the cradle-to-gate LCIs for 15 surfactants and 17 precursors. In this paper, only the findings for the total PED and the GWP are presented (Tables 3 and 4). Other impact categories were not calculated and analysed.

Cumulative or primary energy demand per functional unit is considered the most meaningful parameter in judging the energy efficiency/intensity of systems, since losses due to transformation and transport are fully taken into account. It aggregates all forms of energy use over the life cycle and also contains the feedstock energy (Kloepffer 1997).

The indicator GWP summarises and characterises GHG emissions and their potential effect on global warming. This indicator is calculated according to IPCC 2007 and Guinée et al. (2002). Following these methods, Eq. 1 is applied.

Calculation of global warming potential (GWP 100 years)

The biotic carbon uptake is displayed as a negative value. The small amount of biogenic CO2 emissions in the LCIs of fossil-based surfactants results from renewable energy carriers used for electricity generation and transport.

From Tables 3 and 4, it can be seen that the PED for the reportable precursors ranges from 24,782 MJ/tonne for beef tallow to 107,962 MJ/tonne for DMAPA. For the final surfactants, the range is from 41,404 MJ/tonne for CDEA to 76,626 MJ/tonne for C12–C15 AE3.

The GPW for the reportable precursors ranges from − 1989 kg CO2e (coconut oil methyl ester) to 4894 kg CO2e (DMAPA). For the final surfactants, the range is from − 887 kg CO2e (CDEA) to 2674 (C12–C15 AE3). The arithmetic mean of the GWP for the surfactants considered in this study is 1814 kg CO2e.

3.2 Inventories and summary results for the renewable precursors

In the course of this project, LCIs for renewable precursors were developed by PE International based on literature data and expert judgment. This includes crude and refined PO and PKO, crude and refined CNO, beef TA, as well as their respective alcohols and methyl esters. A very significant research and review effort went into this part of the project. The inventories reflect the calculated environmental profiles of these renewables with the best achievable accuracy. A separate publication by Liedke et al. (2017) covers the methodological details applied by ERASM to estimate the greenhouse gas emissions and GWP of oil palm products. The choice of allocation and the underlying methodological approach have a distinct impact on the reported environmental profile.

3.2.1 Oil palm products

The inventories cover three products (crude oil, refined oil, and methyl esters) from two oil palm sources (palm fruit and palm kernel) and two geographies (Malaysia and Indonesia). In addition to these two countries, ‘global mix’ datasets were created that are calculated based on the respective share of palm oil sold on the world market. The declared units are also 1 tonne of the described products. The following can be concluded:

-

From the oil palm products under assessment, production of 1 tonne refined oil has the highest GHG emissions, followed by the crude oil, with the methyl ester having the lowest emissions

-

Products from the palm kernel oil have higher PED and GWP burdens associated with them than the respective products from the palm fruit

-

Oil palm products produced in Indonesia have higher average environmental burdens than the same products produced in Malaysia. The most important contributors to the differences are significantly lower yields and a higher share of cultivation on peatland

-

Emissions from cultivation on peatland and from land use change have the most significant impact on the palm oil product’s GWP

3.2.2 Coconut palm products

The inventories cover three products (crude coconut oil, refined coconut oil, and methyl esters) and two geographies (the Philippines and Indonesia). Based on these two countries, ‘global mix’ datasets were created, that are calculated based on the respective share of coconut sold on the world market. The declared units are 1 tonne of the described products. The following can be concluded:

-

Among the tree coconut oil products under evaluation, production of 1 tonne of coconut oil methyl ester has the highest PED burden, followed by refined coconut oil and then crude coconut oil with the lowest PED. Refined CNO comes out with the highest GWP.

-

Coconut oil products produced in Indonesia have higher average environmental burdens than the same products produced in the Philippines. Differences in yields between the countries and the emissions from land use change in Indonesia are the most relevant variables to explain this difference

-

The parameters evaluated in the sensitivity analysis performed in this study strongly affect the overall results

3.2.3 Beef tallow

The inventory reflects the environmental profile of tallow with the best available accuracy. The European production of tallow is well described in literature and considered as representative dataset for the region of scope. The declared unit is 1 tonne of the described product. The following conclusions could be drawn from the LCI performed:

-

GHG emissions from cattle breeding have the most significant impact on the tallow environmental profile

-

Emissions of high importance are ammonia and nitrogen oxide emissions which mainly cause acidification and eutrophication effects (not reported in this paper), and methane and nitrous oxide emissions which are contributing to global warming effects

-

The choice of allocation and the underlying methodological approach have a strong impact on the environmental profile of tallow. The environmental burden associated with the abattoir and rendering process is low in relation to the cattle breeding

-

There are several uncertainties and potential improvement areas in the calculation of this LCI. Cattle breeding in EU seems to be diverse. It was not possible to assess all breeding systems in the scope of the study. The most important breeding system, bull fattening, was considered.

The summary results for PED and GWP for the products based on the three different renewables precursors are shown in Table 5.

From Table 5, it can be concluded that there is a difference of about a factor of 1.5 between the PED of palm oil/palm kernel oil (PO/PKO) and that of CNO. There is a more significant difference between the GWP of PO/PKO and CNO, where the CNO products have a negative cradle-to-gate GWP (i.e. CO2 fixed from the air during growth dominates the result), while the PO/PKO products already have a net positive GWP. The latter can be attributed mainly to the LUC factor, which is explained more in detail in Liedke et al. (2017).

3.3 General discussion of results and comparison with the CEFIC-Franklin (1994) study

The PED data for the production of the different surfactants and the energy sources are shown in Fig. 4.

CDEA and C16–C18 TEA-quat have the lowest PED values, around 40 GJ/tonne. This is due to the fact that the precursors coconut oil and tallow have low values of PED. The arithmetic PED average value for all surfactants is around 64 GJ/tonne. The PED is dominated by the raw materials, which cover, in most cases, more than 80% of the value, followed by the use of electricity and thermal energy. The impact of the other inputs for the production of the surfactants is less than 3% (data not shown here). For the surfactants based on petrochemicals, the PED is dominated more than 98% by energy from fossil resources used as feedstock material. For the surfactants that are partly based on renewable raw materials, the solar energy that is converted by the plants via photosynthesis and stored in the oil contributes with a major part to the PED. The other renewable energy sources play only a minor role today in the PED, for both renewable and non-renewable surfactants.

One of the objectives of the ERASM SLE (2014) project was to do a time-trend analysis, by comparing the results—where methodologically justified—with those in the CEFIC-Franklin (1994) study. This is important to understand whether one should revisit earlier LCA work, and/or whether energy efficiency gains were made by the sector over time. Therefore, an attempt was made to compare both datasets, bearing in mind the inherent differences listed in Table 2.

PED is an indicator for which some information can be gleaned from a comparison between the two studies. Figure 5 shows the respective data for surfactants and ethylene oxide. The PED for the updated surfactant LCIs is in the same order of magnitude compared to 1994, which is reassuring for the technical quality of the work carried out independently in both time periods. Seven out of nine substances (C12–C13 E2S, ethylene oxide (EO), C12–C15 AE3, C12–C15 AE7, C12–C14 E2S, C12–C14 AE3, and C12–C14 AE7) now show a somewhat lower calculated PED than in 1994. This can likely be explained by improved process- and energy-efficiency. By contrast, HLAS and C12–C14 AS show a somewhat higher PED compared to 1994. The difference for HLAS is small and likely attributable to more complete inventories in the current study. The result also excludes the neutralisation step (which was included in the CEFIC-Franklin (1994) study), which would make the difference a bit more pronounced.

For C12–C14 AS, the difference can most likely be attributed to the difference in alcohol precursor mix. Further conclusions about this point cannot be drawn due to the lack of detailed documentation from the CEFIC-Franklin (1994) study, as well as confidentiality requirements imposed on the SLE 2014 study.

Furthermore, the GWP values were compared for four fossil-based surfactants. For the renewable surfactants and precursors, it was deemed impossible to do a meaningful comparison due to major methodological changes in GHG accounting (cf. Table 2), as well as different precursor mixes for the surfactants. Also for the fossil surfactants, the GWP comparison is somewhat handicapped, as besides CO2 only a limited set of GHG emissions were reported in the CEFIC-Franklin (1994) study. Hence, these older numbers were likely somewhat of an underestimation. This can also explain why the change in GWP does not seem well correlated with the change in PED. But, overall, the calculated GWP of these fossil-based surfactants has not changed more than 10% (Fig. 6).

3.4 Sensitivity analysis

In the SLE project, scenario-based sensitivity analysis was undertaken for several parameters and/or assumptions. The most relevant results from the sensitivity analysis are shown in Table 6, comparing the impact of mass allocation versus economic allocation for a number of precursors or surfactants where an allocation decision had to be taken.

The production of palm and coconut oils is fixed by their mass relation from the oil fruit composition itself. Hence, mass allocation was applied. Economic allocation was evaluated but not applied, as the SLE industry partners emphasised the importance of stable LCI results over time, while the absolute and relative prices for renewable oils fluctuate depending on global demand, as they are marketed on stock exchanges.

Beef tallow is made from rendering materials from cattle slaughtering. Rendering materials consists of fat, bones, and carcasses. Economic allocation was chosen in this case for the main reason that cattle are primarily bred for the profit generated by meat and milk. Rendering products are wastes in a traditional sense. In the past, humans have developed strategies to use such wastes, e.g. by extracting edible fat or technically usable fat. It can be seen that this choice has a major impact on the PED and GWP calculation. It should be noted that for the ethanolamines economic allocation was also used.

For the production of palm and palm kernel oil, also other parameter sensitivities were calculated (yield, land use change, peat oxidation, methane emissions from POME treatment). These sensitivities are discussed in detail in Liedke et al. (2017).

Another variable factor in LCA is the regional boundaries. The SLE study uses region- and site-specific electricity grid mixes, thermal energy, and steam supply, including market mixes for the used energy carriers, individually set up for each product system. That means for example that for surfactant production in the UK, the average UK electricity grid mix, site-specific thermal energy, steam supply, water supply, production waste, and waste water treatment are modelled. The impact of variation in electricity mixes of production on the final results was not explored in this paper, but could be subject to further analysis.

It was also evaluated whether statistical variation in results per precursor or final surfactant could be presented, but for confidentiality reasons, most of this information could not be shared with the contributing companies and the public. It should be noted that the created LCIs are average results of at least three production systems per surfactant, combining different production technologies, different regional boundaries, and diverse precursor feedstocks. Therefore, the LCIs cannot depict a company-specific LCI.

3.5 Study limitations and improvement opportunities

PE International reviewed the final report of the CEFIC-Franklin (1994) study and the Tenside journal publications to evaluate the existing information. However, as not all unit process data and documentation were available, and furthermore, the background system (power and steam supply, transport, and fuels) was outdated, the project consortium decided not to use the 1994 data as input for this study. Therefore, a fresh primary data collection with industry partners was started, in total about 60 production site data collections. While overall, a good degree of market and technology representativeness was achieved in the SLE project, it would have been advantageous to have the remaining surfactant producers on board in order to achieve near to 100% coverage.

The current LCI study is cradle-to-(factory)gate. The system boundaries are described in Section 2 and may have some limitations on the applicability of the study, its results, and the interpretation of its findings. Therefore, this study is only applicable to the specific conditions as stated in the chapters above. The results of this assessment are to be used according to the defined goal and scope only (e.g. for studies dealing with surfactants marketed in Europe).

A comprehensive literature-based LCA study was carried out for the production of renewable precursors such as palm kernel oil, coconut oil, and beef tallow. The use of recent literature to generate precursor LCI data and their use as background data in the SLE study is recognised as a limitation. However, the alternative, i.e. a new on-site data collection for the agricultural production and processing steps in various countries, would have been an undertaking beyond ERASM’s goals, time plan, and available resources. Such data are best generated by local producers and/or their associations.

Allocation approaches based on physical properties or economic relations were chosen. The allocation methods were included into the sensitivity assessment and showed that different allocation methods can result in important LCI changes of the described products. The chosen allocation approaches are a limitation to the universal validity of the SLE results and need to be carefully considered.

4 Conclusions

The ERASM SLE 2014 study equips LCA practitioners with up-to-date aggregated LCI datasets for the reference year 2011 for 4 major groups of surfactants, 15 substances in total, plus 17 precursors. We recommend to use these data, as the industry reference value where LCI data are needed for surfactants used in Europe. It must be emphasised that, in general, it is not meaningful to directly compare the environmental profile of surfactants on a mass basis. Surfactants all have their own specific performance profile, physico-chemical and functional characteristics, and are not necessarily interchangeable for a given application. And if they are, some may be more weight-efficient than others. Therefore, a comparison as part of a full cradle-to-grave product system is more relevant. The SLE study has shown that each type of surfactant comes with their own ‘footprint’ of resource requirements and emissions. A comparison of the industry average results versus company-specific data (not published here) allows individual companies to benchmark their own operations.

For reasons of company participation and/or confidentiality requirements the ERASM SLE (2014) project was somewhat limited in the range of surfactants that could be covered. In comparison with the CEFIC-Franklin (1994) study, no updated data have been provided for surfactant classes such as soaps, alkyl poly glucosides (APG), secondary alkane sulphonates (SAS). Also, the data for some intermediates collected by PE International could not be displayed for confidentiality reasons, but are incorporated into the data for the final surfactants. It is recommended that all suppliers continue to complete and update the datasets for their chemicals, in order to achieve a fuller coverage of the whole surfactant spectrum. Similarly, we recommend that updates to the SLE dataset are done more routinely, in particular when a new process or LC(I)A methodology is implemented. When based on good methodological references and IT tools, and as part of existing company work processes, this should not be a major effort.

For those indicators where a time-trend comparison was possible and has been explored, so far (e.g. PED), it appears that the differences between the CEFIC-Franklin (1994) and the ERASM SLE (2014) study are relatively small. This is reassuring for the LCA work that has been performed and published in the meantime based on the CEFIC-Franklin (1994) data. While perhaps a more significant PED decrease would have been expected based on technological and energy efficiency improvements, it has to be taken into account that today’s inventories tend to be more complete in terms of inputs covered. It suggests that in particular, the petro-based processes have reached a high degree of technical maturity and optimisation.

A significant effort and specific interest in this study went into the profiling of the renewable precursors and their supply chain. This was much more complex and resource-intensive than for the well-established petroleum-based precursors and intermediates. The SLE study calculated a significant difference in GWP between PO/PKO and CNO, where the CNO products have a net negative cradle-to-gate GWP, while the PO/PKO products have a net positive GWP. The latter can be mainly attributed to the substantial contribution of the LUC factor.

The data from this project are finding initial uses in e.g. the A.I.S.E. Pilot Project of Product Environmental Footprinting Category Rules (A.I.S.E. 2014; PEF Guidance 2014) and in the EU Commission-led project on the standardisation of Bio-based Products (http://ec.europa.eu/growth/sectors/biotechnology/bio-based-products).

Finally, the ERASM SLE study has illustrated how a large group of (competing) companies and two industry associations can productively collaborate around an environmental topic within legal boundaries. It also shows the value of the ‘trio approach’ to organise effective collaboration around the development of essential LCI datasets in industry. Availability of more and better LCI datasets, and easy exchange across the supply chain and with third parties, is an absolute prerequisite for industry and society to progress on the path of sustainability.

5 Access to the data

The data and information generated by this project are made publicly available via different ‘layers’. The overall project context, goal, scope, and key data/conclusions are provided in this paper. Details on the calculation method for GHG emissions from oil palm products are covered in Liedke et al. (2017).

In addition, for each surfactant and precursor, a 3–5 page ‘Environmental Factsheet’ can be downloaded from ERASM’s website (www.erasm.org). These factsheets contain some more detailed information on the LCI, the processes, PED, and GWP, per individual substance.

The full LCI datasets from the SLE project can be obtained in one of the following data formats: EcoSpold 2.0, ILCD entry level and GaBi, or as Excel files. All these files are made accessible free of charge via the ERASM website. The electronic data formats contain all relevant metadata about the LCIs and their set-up (e.g. representativeness, substance CAS no., allocations used, and geographical scope). Furthermore, the LCI datasets are made available to GaBi software customers. Finally, the data are accessible in ILCD format from the ELCD database (http://eplca.jrc.ec.europa.eu/ELCD3).

Any enquiries about the data should be directed to ERASM.

Change history

05 February 2018

In Table 4 reference to the footnotes should be a, b, and c (instead of 1, 2, and 3)

Notes

ERASM: Environmental & Health Risk Assessment and Management of Surfactants, a research partnership of the European Detergents and Surfactants Industries: A.I.S.E., the international Association for Soaps, Detergents and Maintenance Products, and CESIO, the European Committee of Organic Surfactants and their Intermediates (www.erasm.org).

CEFIC: the European Chemical Industry Council (www.cefic.org).

References

A.I.S.E (2014) A.I.S.E. PEF Pilot on household liquid laundry detergents. Presentation at PEF World Forum, October 2014, Berlin

Arpe H-J (2010) Industrial organic chemistry, 5th edn. Wiley-VCH Verlag, Weinheim

Berna JL, Cavalli L, Renta C (1995) A life cycle inventory for the production of linear alkylbenzene sulphonates in Europe. Tenside Surf Det 32:122–127

CEFIC-Franklin (1994) Resource and environmental profile analysis of petrochemical and oleochemical surfactants produced in Europe. Phase II Final Report (and related reports), Franklin Associates, LTD

Curran MA (2007) Co-product and input allocation approaches for creating life cycle inventory data: a literature review. Int J Life Cycle Assess 1:65–78 Special Issue Ecoinvent database. www.ecoinvent.ch

EP0370273 A1 (1990) Fatty alcohol mixtures and their ethoxylates having low temperature characteristics, May 30, 1990; Karl-Heinz Dr. Schmid, Hans Peter Dr. Kubersky, Günter Dr. Demmering, Alfred Dr. Meffert, Weniger, Henkel KGaA

ERASM SLE (2011) Feasibility study for updating the life cycle inventory data of commercial surfactants production. Final Report of the Pilot Phase, prepared by PE International and ERASM (www.erasm.org), 44 p

ERASM SLE (2014) Surfactant life cycle and ecofootprinting project: updating the life cycle inventories for commercial surfactant production. Final Report by PE International for ERASM (www.erasm.org), 186 p

Ernst M (2012) BASF SE-Verfahren zur Synthese von N, N-Dimethyl-1,3-Diaminopropan (DMAPA), EU-patent EP 1 945 603 B1 (in German)

Franke M et al (1995) A life cycle inventory for the production of petrochemical intermediates in Europe. Tenside Surf Det 32:384–396

GaBi 6 (2013) Dataset documentation for the software-system and databases. LBP, University of Stuttgart and PE international AG, Leinfelden-Echterdingen 2013 (http://documentation.gabi-software.com)

GHG Protocol, WRI and WBCSD (2011) The greenhouse gas protocol: product life cycle accounting and reporting standard. World Resources Institute and World Business Council for Sustainable Development, www.ghgprotocol.org, Accessed 2014

Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning, A, van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn H, van Duin R, MAJ Huijbregts (2002) Handbook on life cycle assessment. Operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background. Kluwer Academic Publishers, Dordrecht, ISBN 1-4020-0228-9, 2002, 692 p

Hirsinger F, Schick K-P (1995) A life-cycle inventory for the production of alcohol sulfates in Europe. Tenside Surf Det 32:128–139

ILCD (2010) European Commission, ILCD Handbook – General guide for Life Cycle Assessment (LCA) - Detailed guidance (http://eplca.jrc.ec.europa.eu)

Intergovernmental Panel on Climate Change (IPCC) (2007) In: Pachauri RK, Reisinger A (eds) IPCC fourth assessment report (AR4), Core Writing Team. IPCC, Geneva

International Standard Organisation (ISO) (2006a) Environmental management—life cycle assessment: principles and framework. ISO 14040, Geneva

International Standard Organisation (ISO) (2006b) Environmental management—life cycle assessment: requirements and guidelines. ISO 14044, Geneva

Kloepffer W (1997) In defense of the cumulative energy demand. Editorial Int J Life Cycle Assess 2(2):61

Kocal JA et al (2001) Production of linear alkylbenzene. Appl Catal A Gen 221:295–301

Liedke A, Eggers D, Gruenenwald T, Mckeown P, Schneider C, Schowanek D, Gonzalez M, Lehmann A (2017) Calculation of greenhouse gas (GHG) emissions caused by direct land use change and cultivation on peat soil for palm kernel oil-based precursors of surfactants. Report for the ERASM Surfactant Life Cycle and Ecofootprinting (SLE) Project, July 2017. http://www.erasm.org

PEF Guidance (2014) Guidance for the implementation of the EU PEF during the EF pilot phase—Version 4.0 (http://ec.europa.eu/environment/eussd/smgp/pef_pilots.htm)

Plastics Europe (2011) Eco-profiles and environmental declarations, PlasticsEurope, Version 2.0 (April 2011)

Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T, Schmidt W-P, Suh S, Weidema BP, Pennington DW (2004) Life cycle assessment: part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30:701–720

Russel A, Ekvall T, Baumann H (2005) Life cycle assessment—introduction and overview. J Clean Prod 13:1207–1210

Rosenbaum R et al (2008) USEtox—the UNEP-SETAC toxicity model: recommended characterization factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int J Life Cycle Assess 13:532–546

Schul W, Hirsinger F, Schick K-P (1995) A life-cycle inventory for the production of detergent range alcohol ethoxylates in Europe. Tenside Surf Det 32:171–192

SoFi Software (2007-2016) Enterprise sustainability software, thinkstep AG, copyright, TM, Stuttgart, Echterdingen. (http://www.sofi-software.com)

Stalmans M, Berenbold H, Berna JL, Cavalli L, Dillarstone A, Franke M, Hirsinger F, Janzen D, Kosswig K, Postlethwaite D, Rappert T, Renta C, Scharer D, Schick K-P, Schul W, Thomas H, Van Sloten R (1995) European life-cycle inventory for detergent surfactants production. Tenside Surf Det 32:84–109

Thomas H (1995) A life-cycle inventory for the production of alcohol ethoxy sulphates in Europe. Tenside Surf Det 32:140–151

Van Cauwenberge G (2009) BASF SE, Method for producing ethylene amines and ethanol amines from monoethylene glycol (MEG). Patent WO 2007093514 A1

Ullmann (2010) Ullmann’s encyclopedia of industrial chemistry. John Wiley & Sons, Inc., Hoboken

UNEP (2011) UNEP/SETAC, Global guidance principles for Life Cycle Assessment databases—a basis for greener processes and products, 2011

US 6740783 B1 (2004) Process for preparing dimethyl ether from crude methanol, May 25, 2004, Ki-Won Jun, Hyun-Seog Roh, Kew Ho Lee

Zoller U, Sosis, P (2008) Handbook of detergents: part F: production, vol 142. CRC Press, Boca Raton

Acknowledgments

The authors want to acknowledge ERASM (www.erasm.org) for funding this project. ERASM was created in 1991 and is a joint platform of the European detergent and surfactants producers represented by their associations A.I.S.E (Association Internationale de la Savonnerie, de la Détergence et des Produits d’Entretien) and CESIO (Comité Européen des Agents Surface et de leurs Intermédiaires Organiques). ERASM initiates and coordinates joint industry activities for improving and enlarging the basis for and the knowledge about the risk assessment and sustainability of detergent-based surfactants in environmental compartments.

Additional members of the SLE task force and/or participating companies that have contributed expertise to the project are Xavier González (Kao), Florent Schuschitz (Stepan), Anne Thomasson (Solvay Novecare), Mark Stalmans (P&G), Gert Vanhoof (P&G), Tom Inslegers (P&G), Wolfgang Leonhardt (Evonik), and Luis Gamez Lopez (CEPSA).

The authors also wish to acknowledge the team of PE International/thinkstep who have actively contributed to the study: Cecilia Makishi Colodel, Anja Lehmann, Alexander Liedke, Sabine Deimling, Maria Fernanda Gonzalez, Garance Wilbert, Sebastian Gollnow, and Thilo Kupfer. Diana Eggers is currently with Quantis.

Tim Killeen (formerly with WWF) and the RSPO (Roundtable on Sustainable Palm Oil) are thanked for providing early access to scientific papers with recent information on land use in countries of interest.

Finally, we wish to thank the peer reviewers, Walter Kloepffer, Yannick Leguern, Charlotte Petiot, and Jannick Schmidt, for their guidance and input to the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Chris Yuan

A correction to this article is available online at https://doi.org/10.1007/s11367-018-1437-9.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Schowanek, D., Borsboom-Patel, T., Bouvy, A. et al. New and updated life cycle inventories for surfactants used in European detergents: summary of the ERASM surfactant life cycle and ecofootprinting project. Int J Life Cycle Assess 23, 867–886 (2018). https://doi.org/10.1007/s11367-017-1384-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1384-x