Abstract

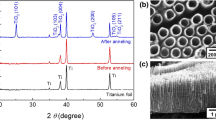

The mechanism of the conversion of titanate nanotubes into nanoribbons is of considerable interest. The details of the transformation processes involved when nanoribbons are produced from a P25 TiO2 powder precursor by alkaline hydrothermal treatment have been investigated systematically by transmission electron microscopy. A multistep attachment model is proposed for the growth at the early stage of coarsening. The treatment duration has a strong effect on the change in product morphology from hollow nanotubes into nanoribbons, since the nanotubes cannot retain their morphology in the strong alkaline solution for extended periods of time. Most of the nanotubes were etched and dissolved, providing the nutrients for subsequent nanoribbon growth. Some stable nanotubes grew spirally internally to form nanowires or became connected together to form rafts which acted as the grains for nanoribbon growth. With increasing hydrothermal time, a large number of nanotubes and other fragments became attached to the grains which began to grow larger and eventually formed the nanoribbons, in a process in which the stepped faces and kinked faces became fused and were eliminated while the flat faces were retained in the nanoribbon morphology.

Similar content being viewed by others

References

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K. Formation of titanium oxide nanotube. Langmuir, 1998, 14: 3160–3163

Chen GHD, Zhang S, Peng LM. The structure of trititanate nanotubes. Acta Crystallographica Section B, 2002, 58: 587–593

Yuan ZY, Colomer JF, Su BL. Titanium oxide nanoribbons. Chem Phys Lett, 2002, 363: 362–366

Bavykin JMF, Walsh FC. Protonated titanates and TiO2 nanostruc-tured materials: Synthesis, properties, and applications. Adv Mater, 2006,18: 2807–2824

Chen Q, Zhou WZ, Du GH, Peng LM. Trititanate nanotubes made via a single alkali treatment. Adv Mater, 2002, 14: 1208–1211

Tsai CC, Teng H. Structural features of nanotubes synthesized from NaOH treatment on TiO2 with different post-treatments. Chem Mater, 2005, 18: 367–373

Wu D, Liu J, Zhao X, Li A, Chen Y, Ming N. Sequence of events for the formation of titanate nanotubes, nanofibers, nanowires, and nanobelts. Chem Mater, 2005, 18: 547–553

Wen BM, Liu CY, Liu Y. Solvothermal synthesis of ultralong single-crystalline TiO2 nanowires. New J Chem, 2005, 29: 969–971

Armstrong AR, Armstrong G, Canales J, Bruce PG. TiO2-B nanowires. Angew Chem-Int Edit, 2004, 43: 2286–2288

Song SA, Liu ZW, He ZQ, Zhang AL, Chen JM. Impacts of morphology and crystallite phases of titanium oxide on the catalytic ozonation of phenol. Environ Sci Technol, 2010, 44: 3913–3918

Xiao D. Template synthesis of N-F-codoped TiO2 nanotubes with high visible light activity. Sci China Ser B-Chem, 2009, 52: 2043–2046

Bavykin DV, Lapkin AA, Plucinski PK, Friedrich JM, Walsh FC. Reversible storage of molecular hydrogen by sorption into multilayered TiO2 nanotubes. J Phys Chem B, 2005, 109: 19422–19427

Xu JW, Ha CH, Cao B, Zhang WF. Electrochemical properties of anatase TiO2 nanotubes as an anode material for lithium-ion batteries. Electrochimica Acta, 2007, 52: 8044–8047

Adachi M, Okada I, Ngamsinlapasathian S, Murata Y, Yoshikawa S. Dye-sensitized solar cells using semiconductor thin film composed of titania nanotubes. Electrochemistry, 2002, 70: 449–452

Uchida S, Chiba R, Tomiha M, Masaki N, Shirai M. Application of titania nanotubes to a dye-sensitized solar cell. Electrochemistry, 2002, 70: 418–420

Sheng J, Hu L, Xu S, Liu W, Mo Le, Tian H, Dai S. Characteristics of dye-sensitized solar cells based on the TiO2 nanotube/nanoparticle composite electrodes. J Mater Chem, 2011, 21: 5457–5463

Riss A, Elser MJ, Bernardi J, Diwald O. Stability and photoelectronic properties of layered titanate nanostructures. J Amer Chem Soc, 2009, 131: 6198–6206

Humar M, Arcon D, Umek P, Skarabot M, Musevic I, Bregar G. Mechanical properties of titania-derived nanoribbons. Nanotechnology, 2006, 17: 3869–3872

Yuan ZY, Su BL. Titanium oxide nanotubes, nanofibers and nanowires. Colloids Surf A, 2004, 241: 173–183

Wei M, Konishi Y, Zhou H, Sugihara H, Arakawa H. A simple method to synthesize nanowires titanium dioxide from layered titanate particles. Chem Phys Lett, 2004, 400: 231–234

Ma RZ, Fukuda K, Sasaki T, Osada M, Bando Y. Structural features of titanate nanotubes/nanobelts revealed by Raman, X-ray absorption fine structure and electron diffraction characterizations. J Phys Chem B, 2005, 109: 6210–6214

Yu HG, Yu JG, Cheng B, Zhou MH. Effects of hydrothermal post-treatment on microstructures and morphology of titanate nanoribbons. J Solid State Chem, 2006, 179: 349–354

Bavykin DV, Parmon VN, Lapkin AA, Walsh FC. The effect of hydrothermal conditions on the mesoporous structure of TiO2 nano-tubes. J Mater Chem, 2004, 14: 3370–3377

Elsanousi A, Elssfah EM, Zhang J, Lin J, Song HS, Tang C. Hydrothermal treatment duration effect on the transformation of titanate nanotubes into nanoribbons. J Phys Chem C, 2007, 111: 14353–14357

Feng XJ, Shankar K, Varghese OK, Paulose M, Latempa TJ, Grimes CA. Vertically aligned single crystal TiO2 nanowire arrays grown directly on transparent conducting oxide coated glass: Synthesis details and applications. Nano Lett, 2008, 8: 3781–3786

Papa AL, Millot N, Saviot L, Chassagnon R, Heintz O. Effect of reaction parameters on composition and morphology of titanate nanomaterials. J Phys Chem C, 2009, 113: 12682–12689

Bavykin DV, Walsh FC. Elongated titanate nanostructures and their applications. Eur J Inorg Chem, 2009, 977-997

Yao BD, Chan YF, Zhang XY, Zhang WF, Yang ZY, Wang N. Formation mechanism of TiO2 nanotubes. Appl Phys Lett, 2003, 82: 281–283

Pina CM, Becker U, Risthaus P, Bosbach D, Putnis A. Molecular-scale mechanisms of crystal growth in barite. Nature, 1998, 395: 483–486

Koutsopoulos S. Kinetic study on the crystal growth of hydroxyapatite. Langmuir, 2001, 17: 8092–8097

Cahn JW, Hoffman DW. Vector thermodynamics for anisotropic surfaces curved and faceted surfaces. Acta Metallurgica, 1974, 22: 1205–1214

Donnay JDH, Harker D. A new law of crystal morphology extending the law of bravais. Amer Miner, 1937, 22: 446–467

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheng, J., Hu, L., Mo, L. et al. A multistep attachment process: Transformation of titanate nanotubes into nanoribbons. Sci. China Chem. 55, 368–372 (2012). https://doi.org/10.1007/s11426-011-4362-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-011-4362-3