Abstract

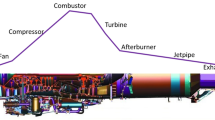

In-service Very-High-Cycle-Fatigue (VHCF) regime of compressor vane and turbine rotor blades of the Al-based alloy VD-17 and superalloy GS6K, respectively, was considered. Surface crack origination occurred at the lifetime more than 1500 hours for vanes and after 550 hours for turbine blades. Performed fractographic investigations have shown that subsurface crack origination in vanes took place inspite of corrosion pittings on the blade surface. This material behavior reflected lifetime limit that was reached by the criterion VHCF. In superalloy GS6K subsurface fatigue cracking took place with the appearance of flat facet. This phenomenon was discussed and compared with specimens cracking of the same superalloy but prepared by the powder technology. In turbine blades VHCF regime appeared because of resonance of blades under the influenced gas stream. Both cases of compressor-vanes and turbine blades in-service cracking were discussed with crack growth period and stress equivalent estimations. Recommendations to continue aircrafts airworthiness were made for in-service blades.

Similar content being viewed by others

Abbreviations

- a :

-

crack length in the depth

- area :

-

area of crack origination zone

- c :

-

crack length by the surface of the semi-elliptically-shaped crack

- h 1 :

-

spacing of meso-beach-marks 1 (MBM1)

- HV :

-

Vickers hardness

- N f :

-

number of cycles to failure (durability)

- (N p)1 :

-

crack growth period calculated based on spacing of beach-marks MBM1

- (Δ q σ) i :

-

range of stress for bifurcation area of S-N curves

- ɛ :

-

tensile deformation

- λ :

-

ratio of biaxial cyclic stresses (σ2/σ1)

- σ a :

-

stress amplitude

- (σ e)1 :

-

tensile stress equivalent value

- σ U :

-

ultimate tensile stress

- σ 0.2 :

-

0.2% offset yield strength

- σ 1 :

-

tensile stress opening the fatigue crack

- σ 2 :

-

tensile or compressive stress acting in a perpendicular direction to the

- σ1 :

-

direction

- σ i :

-

tensile stress opening the fatigue crack

- σ wi :

-

mean stress for bifurcation i-area

References

Shanyavskiy A A. Tolerance fatigue cracking of in-service aircraft structures. In: Synergetics in Engineering Application. Ufa, Russia: Publishing House of Scientific and Technical Literature Monography, 2003. 566–628

Shanyavskiy A A. Fatigue limit—Material property as an opened or closed system? Practical view on the aircraft components failures in GCF area. Int J Fatigue, 2006, 28: 1647–1657

Shanyavskiy A A. Modeling of metals fatigue cracking. In: Synergetics in Aviation. Ufa, Russia: Publishing House of Scientific and Technical Literature Monograph, 2007. 284–498

Shanyavskiy A A. Bifurcation diagram for in-service fatigued metals. Proc Eng, 2010, 2(1): 241–251

Shanyavsky A A. Synergetical models of fatigue-surface appearance in metals: The scale levels of self-organization, the rotation effects, and density of fracture energy. In: Frantsiskony, ed. PROBAMAT-21st Century: Probabilities and Materials. Netherlands: Kluwer Academic Publisher, 1998. 11–44

Ivanova V S. Synergetics, Strength and Fracture of Metallic Materials. Cambridge: Cambridge International Science Publishing, 1998. 26–74

Murakami Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions. Oxford: Elsevier, 2002. 56–89

Sakai T, Ochi Y. Very high cycle fatigue. In: Proc. Third Intern Conf VHCF-3, September 16–19, 2004, Ritsumeikan University, Kusatsu, Japan, 2004. 40–208

Bathias C, Paris P C. Gigacycle fatigue in mechanical practice. Marcel Dekker, NY, USA, 2005. 87–257

Berger C, Christ H J. Very high cycle fatigue (VHCF 5). In: Proc. Int. Conf. VHCF5, DVM, June 28–30, 2011, Berlin, Germany, 2011. 59–107

Shanyavskiy A A, Potapenko Yu. In-service very-high-cycle-fatigue of titanium compressor blades of aircraft engines. In: Allison J E, Jones J W, Larsen J M, Ritchie R O, eds. Proceeding of Fourth Int. Conf. on Very High Cycle Fatigue (VHCF-4), TMS, USA, 2007. 163–168

Palin-Luk T, Perez-Mora R, Bathias C, et al. Fatigue crack initiation and growth on steel in very high cycle regime with sea corrosion. Eng Fracture Mech, 2010, 77: 1953–1962

Shanyavskiy A A, Koltsun Y I. Near-bifurcation fatigue cracking of the surface-hardened and notched metallic rods. In: Yates J R, ed. Proceedings of Int. Conf. “Fatigue 2007”, Cambridge, UK, 2007. 235–241 (CD)

Shanyavskiy A. Mechanisms of the 2024-T351 Al-Alloy fatigue cracking in bifurcation area after laser shocks hardening procedure. Key Eng Mater, 2011, 465: 511–514

Shanyavskiy A A. Fatigue cracking of smooth and notched specimens of compacted superalloy EP741 NP in high- and very-high-cycle-fatigue regime. In: Berger C, Christ H-J, eds. Proceeding of Int. Conf. VHCF5, DVM, June 28–30, 2011, Berlin, Germany 2011. 107–112

Shanyavskiy A, Banov M. The twisting mechanism of subsurface fatigue cracking in Ti-6Al-2Sn-4Zr-2Mo-0.1Si alloy. Eng Fracture Mech, 2010, 77: 1896–1906

Birger I A, Shorr B F, Iosilevich U B. Strength calculation for structures. Moscow, Mashinostroenie, 1993. 287–295

McEvily A J, Endo M. A method for the prediction of the influence of flaws on the fatigue strength under biaxial loading. In: Sonsino C M, Zenneer H, Portella P D, eds. Proceedings of Seventh Intern. Conf. Biaxial/Multiaxial Fatigue Fract., June 28–July 1, Berlin, Germany, 2004. 247–252

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shanyavskiy, A.A. Very-High-Cycle-Fatigue of in-service air-engine blades, compressor and turbine. Sci. China Phys. Mech. Astron. 57, 19–29 (2014). https://doi.org/10.1007/s11433-013-5364-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-013-5364-2