Abstract

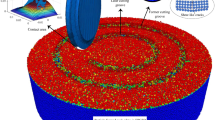

The use of tunnel boring machines (TBMs) is increasingly popular in tunnelling. One of the most important aspects in the use of these machines is to assess with certain accuracy the effectiveness of the action of the discs on the cutter-head in the different rock types to be excavated. A specific machine, called an intermediate linear cutting machine (ILCM), has been developed at the Politecnico di Torino in order to study, on a reduced scale in detail in the laboratory, the interaction between the discs of the TBM and the rock: this machine allows a series of grooves to be cut on a rock sample of 0.5 × 0.3 × 0.2 m, through the rolling of a 6.5-in. disc, and evaluation, during testing, of the parameters associated with the action of the cutting tool. The parameters measured during the tests were compared with the results obtained employing two analytical methods widely used for predicting the performance of TBMs: the Colorado School of Mines (CSM) model and the Norwegian University of Science and Technology (NTNU) model. The latter showed a greater ability to reproduce tests conducted using the ILCM. However, as with the CSM model, it does not allow the optimal excavation condition (the ratio, which minimizes the specific energy of excavation, between the groove spacing and the penetration of the disc), necessary for the correct design of the TBM cutter-head, to be identified. An example, based on a real case of a tunnel in Northern Italy, allowed a demonstration of how the NTNU model provides results in line with the measurements taken during the excavation and represents, therefore, a model that is able to reliably simulate both laboratory tests and the action of a TBM on site. The NTNU model, together with the results of the tests with ILCM targeted on the identification of the optimal conditions of excavation, may allow the correct dimensioning of the TBM cutter-head to be attained in order to effectively implement the excavation.

Similar content being viewed by others

References

Ates U, Bilgin N, Copur H (2014) Estimating torque, thrust and other design parameters of different type TBMs with some criticism to TBMs used in Turkish tunneling projects. Tunn Undergr Space Technol 40:46–63

Balci C, Bilgin N (2007) Correlative study of linear small and full scale rock cutting tests to select mechanized excavation machines. Int J Rock Mech Min Sci 44:468–476

Benato A, Oreste P (2015) Prediction of penetration per revolution in TBM tunneling as a function of intact rock and rock mass characteristics. Int J Rock Mech Min Sci 74:119–127

Bilgin N, Balci C, Tumac D, Feridunoglu C, Copur H (2010) Development of a portable rock cutting rig for rock cuttability determination. In: International Society for Rock Mechanics. Taylor & Francis Group. ISRM international symposium (EUROCK), 15–18 June, Lausanne, Switzerland

Blindheim OT, Bruland A (1998) Boreability testing. Norwegian TBM tunneling. Norwegian Soil and Rock Engineering Association, Oslo

Bruland A (1998) Prediction model for performance and costs. Norwegian TBM tunneling. Norwegian Soil and Rock Engineering Association, Oslo

Chang SH, Choi SW, Bae GJ, Jeon S (2006) Performance prediction of TBM disc cutting on granitic rock by the linear cutting test. Tunn Undergr Space Technol 21(3–4):271

Cho JW, Jeon S, Jeong HY, Chang SH (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35:37–54

Copur H, Tuncdemir H, Bilgin N, Dincer T (2001) Specific energy as a criterion for use of rapid excavation systems in Turkish mines. Trans Inst Min Metall Sect A 110:A149–A157

Entacher M, Lorenz S, Galler R (2014) Tunnel boring machine performance prediction with scaled rock cutting tests. Int J Rock Mech Min Sci 70:450–459

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado Red Granite: Implications for TBM performance prediction. Int J Rock Mech Min Sci 44(2):238–246

Giunta G (2012) Confronti analitici tra metodi previsionali dell’avanzamento delle TBM in roccia. Bachelor thesis, Politecnico di Torino, Italy

Innaurato N, Oggeri C, Oreste P, Vinai R (2007) Experimental and numerical studies on rock breaking with TBM tools under high stress confinement. Rock Mech Rock Eng 40(5):429–451

Innaurato N, Oreste P (2011) Deep tunnel excavations using tunnel boring machines. Arch Min Sci 56(3):537–549

Innaurato N, Oreste P (2011) Theoretical study on the TBM tool-rock interaction. Geotech Geol Eng 29(3):297–305

Oggeri C, Oreste P (2012) The wear of tunnel boring machine excavation tools in rock. Am J Appl Sci 9(10):1606–1617

Ozdemir L, Nilsen B (1999) Recommended laboratory rock testing for TBM projects. AUA News 14(2):21–35

Rostami J, Ozdemir L (1993) A new model for performance prediction of hard rock TBMs. In: Proceedings of rapid excavation and tunneling conference (RETC), pp 793–809

Rostami J, Gertsch R, Gertsch L (2002) Rock fragmentation by disc cutter, a critical review and an update. In: Proceedings of North American rock mechanics symposium (NARMS’ 02), Toronto, Ontario

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12(12):361–366

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci Geomech Abstr 22(3):153–161

Snowdon RA, Ryley MD, Temporal J (1982) A study of disc cutting in selected British rocks. Int J Rock Mech Min Sci Geomech Abstr 19(3):107–121

Tomasini M (2012) Valutazione delle caratteristiche geomeccaniche dell’ammasso roccioso tramite valutazione dei parametri di scavo della TBM, per la galleria stradale di Ceppo Morelli (VB). Bachelor thesis. Politecnico di Torino, Italy

Tuncdemir H, Bilgin N, Copur H, Balci C (2008) Control of rock cutting efficiency by muck size. Int J Rock Mech Min Sci 45(2):278–288

Yin LJ, Gong QM, Zhao J (2014) Study on rock mass boreability by TBM penetration test under different in situ stress conditions. Tunn Undergr Space Technol 43:413–425

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cardu, M., Iabichino, G., Oreste, P. et al. Experimental and analytical studies of the parameters influencing the action of TBM disc tools in tunnelling. Acta Geotech. 12, 293–304 (2017). https://doi.org/10.1007/s11440-016-0453-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-016-0453-9