Abstract

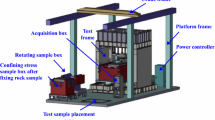

In this study, determination of some machine parameters and performance prediction for tunnel boring machine (TBM) are conducted based on laboratory rock cutting test. Firstly, laboratory full-scale linear cutting test is carried out using 432-mm CCS (constant cross section) disc cutter in Chongqing Sandstone. Then, the input parameters for TBM cutterhead design are extracted; some TBM specifications are determined and then compared to the manufactured values. Finally, laboratory full-scale linear cutting test results are compared with the field TBM excavation performance data collected in Chongqing Yangtze River Tunnel. Results show that laboratory full-scale linear cutting test results, combined with some engineering considerations, can be used for the preliminary and rough design of TBM machine capacity. Meanwhile, combined with some modification factors, it can also well predict the field TBM excavation performance.

Similar content being viewed by others

References

Abu Bakar MZ, Gertsch L, Rostami J (2014) Evaluation of fragments from disc cutting of dry and saturated sandstone. Rock Mech Rock Eng 47(5):1891–1903. https://doi.org/10.1007/s00603-013-0482-8

Balci C (2009) Correlation of rock cutting tests with field performance of a TBM in a highly fractured rock formation: a case study in Kozyatagi-Kadikoy metro tunnel, Turkey. Tunn Undergr Space Technol 24(4):423–435. https://doi.org/10.1016/j.tust.2008.12.001

Balci C, Tumac D (2012) Investigation into the effects of different rocks on rock cuttability by a V-type disc cutter. Tunn Undergr Space Technol 30(4):183–193. https://doi.org/10.1016/j.tust.2012.02.018

Barton N (2000) TBM tunnelling in jointed and faulted rock. Balkema, Rotterdam

Bilgin N, Copur H, Balci C, Tumac D, Akgul M, Yuksel A (2008) The selection of a TBM using full scale laboratory tests and comparison of measured and predicted performance values in Istanbul Kozyatagi-Kadikoy metro tunnels. In: World tunnel congress 2008-underground facilities for better environment and safety, India

Bruland A (1998) Hard rock tunnel boring. Ph.D. thesis, Norwegian University of Science and Technology, Trondheim, Norway

Cardu M, Iabichino G, Oreste P, Rispoli A (2017) Experimental and analytical studies of the parameters influencing the action of TBM disc tools in tunnelling. Acta Geotech 12(2):293–304. https://doi.org/10.1007/s11440-016-0453-9

Chen LH, Labuz JF (2006) Indentation of rock by wedge-shaped tools. Int J Rock Mech Min Sci 43(7):1023–1033. https://doi.org/10.1016/j.ijrmms.2006.03.005

Cho JW, Jeon S, Yu SH, Chang SH (2010) Optimum spacing of TBM disc cutters: a numerical simulation using the three-dimensional dynamic fracturing method. Tunn Undergr Space Technol 25(3):230–244. https://doi.org/10.1016/j.tust.2009.11.007

Cho JW, Jeon S, Jeong HY, Chang SH (2013) Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement. Tunn Undergr Space Technol 35(4):37–54. https://doi.org/10.1016/j.tust.2012.08.006

Choi SW, Chang SH, Park YT, Lee GP, Bae GJ (2014) Comparative analysis of cutter acting forces and axial stresses of single and double disc cutters by linear cutting tests. J Korean Tunn Undergr Space Assoc 16(2):181–191. https://doi.org/10.9711/KTAJ.2014.16.2.181 (in Korean)

Commission on Engineering and Technical Systems of USA (1984) Geotechnical site investigation for underground projects 2:182. http://www.nap.edu/html/919/NI000102.pdf. Accessed 1 Aug 2017

Copur H, Aydin H, Bilgin N, Balci C, Tumac D, Dayanc C (2014) Predicting performance of EPB TBMs by using a stochastic model implemented into a deterministic model. Tunn Undergr Space Technol 42(3):1–14. https://doi.org/10.1016/j.tust.2014.01.006

Frenzel C, Käsling H, Thuro K (2008) Factors influencing disc cutter wear. Geomech Tunn 1:55–60. https://doi.org/10.1002/geot.200800006

Fukui K, Okubo S (1999) Rock-properties estimation by TBM cutting force. In: 9th international congress on rock mechanics, vol 2, pp 1217–1220

Fukui K, Okubo S (2006) Some attempts for estimating rock strength and rock mass classification from cutting force and investigation of optimum operation of tunnel boring machines. Rock Mech Rock Eng 39(1):25–44. https://doi.org/10.1007/s00603-005-0071-6

Geng Q, Wei ZY, Meng H, Chen Q (2016) Numerical and experimental research on the rock-breaking process of tunnel boring machine normal disc cutters. J Mech Sci Technol 30(4):1733–1745. https://doi.org/10.1007/s12206-016-0329-9

Gertsch R (1993) Tunnel boring machine disk cutter vibrations. MS thesis, Colorado School of Mines, Golden, USA

Gertsch R (2000) Rock toughness and disc cutting. Ph.D. thesis, University of Missouri, Rolla, USA

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado Red Granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44(2):238–246. https://doi.org/10.1016/j.ijrmms.2006.07.007

Gong QM, Zhao J, Jiao YY (2005) Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 20:183–191. https://doi.org/10.1016/j.tust.2004.08.006

Gong QM, Jiao YY, Zhao J (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21:46–55. https://doi.org/10.1016/j.tust.2005.06.004

Gong QM, Zhao J, Jiang YS (2007) In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn Undergr Space Technol 22(3):303–316. https://doi.org/10.1016/j.tust.2006.07.003

Gong QM, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46(1):8–18. https://doi.org/10.1016/j.ijrmms.2008.03.003

Gong QM, He GW, Zhao XB, Ma HS, Li XZ, Zhang H, Miao CT (2015) Influence of different cutter spacings on rock fragmentation efficiency of Beishan granite by TBM. Chin J Geotech Eng 37(1):54–60 (in Chinese)

Gong QM, Dong GL, Yin LJ, Ma S, Lu JW (2016) Comparison study on the rock linear and rotating cutting tests by TBM cutter. Constr Technol 46(11):61–66 (in Chinese)

Gong QM, Du XL, Li Z, Wang QX (2016) Development of a mechanical rock breakage experimental platform. Tunn Undergr Space Technol 57:129–136. https://doi.org/10.1016/j.tust.2016.02.019

Gong QM, He GW, Zhao XB, Zhang H, Miao CT, Yao XH, Li XZ (2016) Influence of penetration on the rock-breakage efficiency of a TBM cutter. Mod Tunn Technol 53(1):62–68. https://doi.org/10.13807/j.cnki.mtt.2016.01.010 (in Chinese)

Gong QM, Yin LJ, Ma HS, Zhao J (2016) TBM tunnelling under adverse geological conditions: an overview. Tunn Undergr Space Technol 57:4–17. https://doi.org/10.1016/j.tust.2016.04.002

Liu QS, Liu JP, Pan YC, Kong XX, Cui XZ, Huang SB, Wei L (2016) Research advances of tunnel boring machine performance prediction models for hard rock. Chin J Rock Mech Eng 35(S1):2766–2786. https://doi.org/10.13722/j.cnki.jrme.2014.1601 (in Chinese)

Liu QS, Pan YC, Liu JP, Kong XX, Shi K (2016) Comparison and discussion on fragmentation behavior of soft rock in multi-indentation tests by a single TBM disc cutter. Tunn Undergr Space Technol 57:151–161. https://doi.org/10.1016/j.tust.2016.02.021

Liu QS, Pan YC, Kong XX, Liu JP, Shi K, Cui XZ, Huang SB (2016) Experimental investigation on mudstone fragmentation characteristics in indentation process by TBM disc cutter. Rock Soil Mech 37(S1):166–174. https://doi.org/10.16285/j.rsm.2016.S1.022 (in Chinese)

Liu QS, Pan YC, Liu JP, Kong XX, Shi K, Liu Q (2016) Analysis on fragmentation behavior of rocks in indentation tests by disc cutter. Chin J Rock Mech Eng 35(S2):3516–3525. https://doi.org/10.13722/j.cnki.jrme.2015.0532 (in Chinese)

Ma HS, Yin LJ, Ji HG (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int J Rock Mech Min Sci 48(6):1021–1033. https://doi.org/10.1016/j.ijrmms.2011.05.002

Ma HS, Gong QM, Wang J, Yin LJ, Zhao XB (2016) Study on the influence of confining stress on TBM performance in granite rock by linear cutting test. Tunn Undergr Space Technol 57:145–150. https://doi.org/10.1016/j.tust.2016.02.020

Ma HS, Gong QM, Wang J, Zhao XB, Yin LJ, Miao CT, He GW (2016) Linear cutting tests on effect of confining stress on rock fragmentation by TBM cutter. Chin J Rock Mech Eng 35(2):346–355. https://doi.org/10.13722/j.cnki.jrme.2014.0926 (in Chinese)

Moon T, Oh J (2012) A study of optimal rock-cutting conditions for hard rock TBM using the discrete element method. Rock Mech Rock Eng 45(5):837–849. https://doi.org/10.1007/s00603-011-0180-3

Ramezanzadeh A, Rostami J, Kastner R (2003) Performance prediction models for hard rock tunnel boring machines. http://iransaze.com/files-for-download/maghale/mohandesi%20tonel/konferans-mohandesi-tonel/Performance%20Prediction%20Models%20for%20Hard%20Rock%20Tunnel%20Boring%20Machines.pdf. Accessed 1 Aug 2017

Rostami J (1991) Design optimization, performance predictions, and economic analysis of TBM application in the proposed Yucca mountain nuclear waste repository. MS thesis 4139, Colorado School of Mines, Golden, USA

Rostami J, Ozdemir L (1993) A new model for performance prediction of hard rock TBMs. In: Proceedings of rapid excavation and tunneling conference. USA, pp 794–809. http://emi.mines.edu/UserFiles/File/earthMechanics/disc_cutters/disc_cutter1.PDF. Accessed 1 Aug 2017

Rostami J, Ozdemir L, Nilson B (1996) Comparison between CSM and NTH hard rock TBM performance prediction models. http://emi.mines.edu/UserFiles/File/earthMechanics/seminar/08_01_machine_performance_assessment_and_costing.pdf?textonly=1. Accessed 1 Aug 2017

Rostami J (2013) Study of pressure distribution within the crushed zone in the contact area between rock and disc cutters. Int J Rock Mech Min Sci 57(1):172–186. https://doi.org/10.1016/j.ijrmms.2012.07.031

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12(75):361–366. https://doi.org/10.1016/0148-9062(75)90547-1

Sanio HP (1985) Prediction of the performance of disc cutters in anisotropic rock. Int J Rock Mech Min Sci Geomech Abstr 22(3):153–161. https://doi.org/10.1016/0148-9062(85)93229-2

Song KZ (2005) Analysis on shield driving performance of a tunnel under river in alternation of mud rock and sand rock bed. Ph.D. thesis. Beijing Jiaotong University, Beijing, China (in Chinese)

Tumac D, Balci C (2015) Investigations into the cutting characteristics of CCS type disc cutters and the comparison between experimental, theoretical and empirical force estimations. Tunn Undergr Space Technol 45:84–98. https://doi.org/10.1016/j.tust.2014.09.009

Tuncdemir H, Bilgin N, Copur H, Balci C (2008) Control of rock cutting efficiency by muck size. Int J Rock Mech Min Sci 45(2):278–288. https://doi.org/10.1016/j.ijrmms.2007.04.010

Ulusay R, Hudson JA (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. International Society for Rock Mechanics, Ankara

Yin LJ, Gong QM, Zhao J (2014) Study on rock mass boreability by TBM penetration test under different in situ stress conditions. Tunn Undergr Space Technol 43(7):413–425. https://doi.org/10.1016/j.tust.2014.06.002

Yin LJ, Miao CT, He GW, Dai FC, Gong QM (2016) Study on the influence of joint spacing on rock fragmentation under TBM cutter by linear cutting test. Tunn Undergr Space Technol 57:137–144. https://doi.org/10.1016/j.tust.2016.02.018

Acknowledgements

This work was financially supported by National Key Basic Research Program of China under Grant Nos. 2015CB058102 and 2014CB046904, China Postdoctoral Science Foundation Program under Grant No. 2017M622515, National Natural Science Foundation of China under Grant Nos. 41602326 and 41702254 and National Funded Program for Graduate Students Studying Abroad of China Scholarship Council under Grant No. 201506270068. The authors are grateful for their continuous support and also grateful to the authors’ colleagues for their valuable help in organizing and improving this article, especially to Mr. Shuai Ma in Beijing University of Technology. Prof. Qiuming Gong’s postgraduates in Beijing University of Technology are sincerely acknowledged for helping authors prepare the rock samples and conduct the linear cutting tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, Y., Liu, Q., Kong, X. et al. Full-scale linear cutting test in Chongqing Sandstone and the comparison with field TBM excavation performance. Acta Geotech. 14, 1249–1268 (2019). https://doi.org/10.1007/s11440-018-0702-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-018-0702-1