Abstract

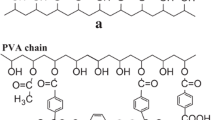

Thin sheets of polyallylamine (PAAm) and polyvinyl alcohol (PVA) blend were prepared by employing solution casting technique for potential membranes application. The blends were characterized by Fourier transform infrared (FTIR) and 1H-NMR spectroscopy, scanning electron microscopy, thermogravimetric analysis, ultraviolet–visible spectroscopy, X-ray diffraction, and mechanical properties. The zeta potential, conductivity and rheological properties of PAAm/PVA blends were also studied. The FTIR spectrum reveals that the C–H asymmetric stretching vibration band of PVA at 2,928 cm−1 disappeared in all the blend samples. Thermal stability of the blend membrane was better than pure polymers. The crystallinity of the PAAm/PVA blends was decreased, which may be due to the entanglement of PAAm in to PVA chains, which is also responsible for the improvement in the mechanical properties of the blends. Zeta potential decreases where as the conductivity increases as a function of temperature. Hydrophilicity is improved by addition of PVA to PAAm, which may be due to hydroxyl group of PVA. The blend solution shows non-Newtonian character of the liquid. By applying shear stress, increase in the effect of rarefaction was observed. The knowledge about the investigated parameters will be of vital importance for use of the blended material in membrane applications, especially where CO2 separation is in focus. The membrane performance (separation properties) of the PAAm/PVA blended material is, however, not reported in the current article.

Similar content being viewed by others

References

Fang H, Mighri F, Ajji A (2007) J Appl Polym Sci 105:2955–2962

Pawde SM, Deshmukh K (2009) J Appl Polym Sci 114:2169–2179

Shen J, Qiu J, Wu L, Gao C (2006) Sep and Purif Tech 51:345–351

Cai Y, Wang Z, Yi C, Bai Y, Wang J, Wang S (2008) J Membr Sci 310:184–196

Robsen LM (1991) J Membr Sci 62:165–185

Kim TJ, Li B, Hagg MB (2004) J Polym Sci Part B Polym Phys 42:4326–4336

Dong C, Wang Z, Yi C, Wang S (2006) J Appl Polym Sci 101:1885–1891

Zhang Y, Wang Z, Wang S (2002) J Appl Polym Sci 86:2222–2226

Zhang Y, Wang Z, Wang S (2002) Chem Lett 31:430–431

Yamasaki A, Shinbo T, Mizoguchi K (1997) J Appl Polym Sci 64:1061–1065

Shibayama M, Sato M, Kimura Y, Fujiwara H, Nomura S (1988) Polymer 29:336–340

Zidan HM (2003) J Appl Polym Sci 88:104–111

Shahawy MAE (2003) Polym Inter 52:1919–1924

Selim SM, Seodi R, Shabaka AA (2005) Mater Lett 59:2650–2654

Galindo-Rosales FJ, Rubio-Hernandez FJ, Velazquez-Navarro JF, Gomez-Merino AI (2007) J Amer Cer Soc 90:1641–1643

Amiri A, Gisle O, Sjoblom S (2009) Colloids Surf A Physicochem Eng Asp 349:43–54

Lianyu L, Fubing P, Zhougyi J, Jianghui W (2006) J Appl Polym Sci 101:167–173

Pawde SM, Deshmukh K, Parab S (2008) J Appl Polym Sci 109:1328–1337

Pawde SM, Deshmukh K (2008) J Appl Polym Sci 109:3431–3437

Shin EJ, Lee YH, Choi SC (2004) J Appl Polym Sci 91:2407–2415

Selvasekarapandian S, Hirankumar G, Kawamura J, Kuwata N, Hattori T (2005) Mater Lett 59:2741–2745

Yu D, Yang J, Xie J (1989) Handbook of analytical chemistry. Part 5: nuclear magnetic resonance. Chemistry Industry Press, Beijing

Petit JM, Zhu XX (1996) Macromolecules 29:2075–2081

Bugay DE (1993) Pharm Res 10:317–327

Guiping M, Dongzhi Y, Dandan S, Xueyan M, John FK, Jun N (2010) Polym Adv Tech 21:189–195

Finch CA (1973) Polyvinyl alcohol properties and application. Wiley, Chichester, p 493

Sperling LH (1992) Introduction to physical polymer science, vol 4, 2nd edn. Wiley Interscience, New York, p 122

Chang MC, Tanaka J (2002) Biomaterials 23:4811–4818

Chunxue Z, Xiaoyan Y, Lili W, Jing S (2006) Acta Polym Sin 1:294–297

Zhang Y, Huang X, Duan B, Wu L, Li S, Yuan X (2007) Coll Polym Sci 285:855–863

ASTM (1985) Zeta potential of colloids in water and waste water. ASTM standard D 4187-82. American Society for Testing and Materials, West Conshohocken

Toshima N, Hara S (1995) Prog Polym Sci 20:155–183

Benseddik E, Makhlouski M, Bernede JC, Lefrant S, Pron A (1995) Syn Met 72:237–242

Dutta P, Biswas S, Ghosh M, De SK, Chatterjee S (2001) Synth Met 122:455–461

Tominaga Y, Asai S, Sumita M, Panero S, Scrosati B (2005) J Pow Sour 146:402–406

Deshmukh RR, Shetty AR (2008) J Appl Polym Sci 107:3707–3717

Pawde SM, Deshmukh K (2009) Polym Eng Sci 49:808–818

Deng L, Kim TJ, Hagg MB (2009) J Membr Sci 340:154–163

Hede PD, Bach P, Jensen AD (2009) Indust Eng Chem Res 48:1905–1913

Bogun M, Mikolajczyk T (2009) J Appl Polym Sci 114:3452–3457

Acknowledgments

Authors wish to thank the Norwegian Research Council for financial support to the work through CCERT project. Sincere thanks to Sondre Volden, Iva Kralowa, Signe Hakonsen, and Asal Amiri from Ugelstad Laboratory at Department of Chemical Engineering, Norwegian University of Science and Technology (NTNU), for their help in using various analytical instruments. The authors would further like to thank Dr. S. L. Kamath from the Indian Institute of Technology (IIT) Mumbai for SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deshmukh, K., Ahmad, J. & Hägg, M.B. Fabrication and characterization of polymer blends consisting of cationic polyallylamine and anionic polyvinyl alcohol. Ionics 20, 957–967 (2014). https://doi.org/10.1007/s11581-013-1062-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-013-1062-3