Abstract

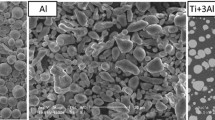

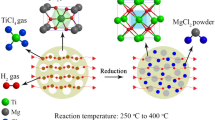

The stability of Ti2AlN at high pressure of 5 GPa and different temperatures of 700–1 600 °C was investigated using X-ray diffraction (XRD), scanning electron microscopy (SEM) equipped with an energy dispersive spectrometer (EDS). Ti2AlN was found to be stable at temperatures as high as 1 400 °C under 5 GPa for 20 min, and was proved that it held better structure stability than Ti2AlC under 5 GPa through comparative experiments of Ti2AlN and Ti2AlC (representative compounds of M 2 AX phases (211 phase)). The reaction process at high pressure had some difference from that at ambient pressure/vacuum, and Ti2AlN directly decomposed to TiN and TiAl at 5 GPa and 1 500 °C for 20 min. Moreover, the mechanism of phase segregation was discussed. In addition, the behavior of Ti2AlN contacting with Zr at high pressure and high temperature (HPHT) was also studied.

Similar content being viewed by others

References

H Nowotny. New Compounds with Eulytine Structure: Crystal Chemistry and Luminescence[J]. Prog. Solid. State. Chem., 1970, 2: 27–30

W Jeitschko, H Nowotny. Die Kristallstructur von Ti3SiC2-Ein Neuer Komplxcarbid-Typ[J]. Monatsh. fur Chem., 1967, 98: 329–37

H Wolfsgruber, H Nowotny, F Benesovsky. Die Kristallstuktur von Ti3GeC2[J]. Monatsh. fur Chem., 1967, 98: 2 401–2 405

M A Pietzka, C Schuster. Summary of Constitutional Data on the Aluminum-Carbon-Titanium System[J]. J. Phase Equilib., 1994, 15: 392–400

S Dubois, T Cabioc’h, P Chartier, et al. A New Ternary Nanolaminate Carbide: Ti3SnC2[J]. J. Am. Ceram. Soc., 2007, 90: 2 642–2 644

J Etzkorn, M Ade, H Hillebrecht. Ta3AlC2 and Ta4AlC3 — Single-Crystal Investigations of Two New Ternary Carbides of Tantalum Synthesized by the Molten Metal Technique[J]. Inorg. Chem., 2007, 46: 1 410–1 418

Y C Zhou, F L Meng, J Zhang. New MAX-Phase Compounds in the V-Cr-Al-C System[J]. J. Am. Ceram. Soc., 2008, 91: 1 357–1 360

C J Rawn, M W Barsoum, T El-Raghy, et al. Structure of Ti4AlN3-A Layered M n+1 AX n Nitrid[J]. Mater. Res. Bull., 2000, 35: 1 785–1 796

A T Procipio, M W Barsoum, El-Raghy T, et al. Characterization of Ti4AlN3[J]. Metall. Mater. Trans. A, 2000, 31: 333–337

B Manoun, S K Saxena, T El-Raghy, et al. High-Pressure X-Ray Diffraction Study of Ta4AlC3[J]. Appl. Phys. Lett., 2006, 88:201 902/1–201 902/3

Z Lin, M Zhuo, Y Zhou, et al. Structural Characterization of a New Layered-Ternary Ta4AlC3 Ceramic[J]. J. Mater. Res., 2006, 21: 2 587–2 592

C Hu, Z Lin, L He, et al. Physical and Mechanical Properties of Bulk Ta4AlC3 Ceramic Prepared by an In-Situ Reaction Synthesis/Hot-Pressing Method[J]. J. Am. Ceram. Soc., 2007, 90(8):2 542–2 548

P Eklund, J-P Palmquist, J Höwing, et al. Ta4AlC3: Phase Determination, Polymorphism and Deformation[J]. Acta Mater., 2007, 55: 4 723–4 729

J-P Palmquist, S Li, P O Å Persson, et al. M n+1 AX n Phases in the Ti-Si-C System Studied by Thin-Film Synthesis and Ab Initio Calculations[J]. Phys. Rev. B, 2004, 70: 165 401/1–165 401/13

H Högberg, L Hultman, J Emmerlich, et al. Growth and Characterization of MAX-Phase Thin Films[J]. Surf. Coat. Technol., 2005, 193: 6–10

P Eklund, A Murugaiah, J Emmerlich, et al. Homoepitaxial Growth of Ti-Si-C MAX-Phase Thin Films on Bulk Ti3SiC2 Substrates[J]. J. Cryst. Growth, 2007, 304: 264–269

H Högberg, P Eklund, J Emmerlich, et al. Rapi d Communications: Epitaxial Ti2GeC, Ti3GeC2, and Ti4GeC3 MAX-Phase Thin Films Grown by Magnetron Sputtering[J]. J. Mater. Res., 2005, 20: 779–782

C Hu, F Li, J Zhang, et al. Nb4AlC3: A New Compound Belonging to the MAX Phases[J]. Scripta Mater., 2007, 57: 893–896

C F Hu, J Zhang, J M Wang, et al. Crystal Structure of V4AlC3: A New Layered Ternary Carbide[J]. J. Am. Ceram. Soc., 2008, 91: 636–639

W Jeitschko, H Nowotny, F Benesovsky. Kohlenstoffhaltige ternäre Verbindungen (H-Phase)[J]. Monatsch. Chem., 1963, 94: 672–676

J C Schuster, J Bauer. The Ternary System Titanium-Aluminium-Nitrogen[J]. J. Solid. State. Chem., 1984, 53: 260–265

M W Barsoum, M Ali, T El-Raghy. Processing and Characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5[J]. Metall. Mater. Trans. A, 2000, 31A: 1 857–1 865

M W Barsoum. The M n+1 AX n Phases: A New Class of Solids; Thermodynamically Stable Nanolaminates[J]. Prog. Solid. State. Chem., 2000, 28: 201–281

J L Jordan, T Sekine, T Kobayashi, et al. High Pressure Behavior of Titanium-Silicon Carbide (Ti3SiC2)[J]. J. Appl. Phys., 2003, 93: 9 639–9 643

B Manoun, H P Liermann, R Gulve, et al. Compression of Ti3Si0.5Ge0.5C2 to 53 GPa[J]. Appl. Phys. Lett., 2004, 84: 2 799–2 801

B Manoun, S K Saxena, H P Liermann, et al. Compression of Zr2InC to 52 GPa[J]. Appl. Phys. Lett., 2004, 85: 1 514–1 516

B Manoun, S K Saxena, M W Barsoum. High Pressure Study of Ti4AlN3 to 55 GPa[J]. Appl. Phys. Lett., 2005, 86:101 906/1–101 906/3

R S Kumar, S Rekhi, A L Cornelius, et al. Compressibility of Nb2AsC to 41 GPa[J]. Appl. Phys. Lett., 2005, 86:111 904/1–111 904/3

B Manoun, R P Gulve, S K Saxena, et al. Compression Behavior of M2AlC (M=Ti, V, Cr, Nb, and Ta) Phases to above 50 GPa[J]. Phys. Rev. B, 2006, 73: 024 110/1–024 110/7

B Manoun, F X Zhang, S K Saxena, et al. X-Ray High-Pressure Study of Ti2AlN and Ti2AlC[J]. J. Phys. Chem. Solids., 2006, 67: 2 091–2 094

B Manoun, H Yang, S K Saxena, et al. Infrared Spectrum and Compressibility of Ti3GeC2 to 51 GPa[J]. J. Alloys. Comp., 2007, 433: 265–268

M Radovic, M W Barsoum, A Ganguly, et al. On the Elastic Properties and Mechanical Damping of Ti3SiC2, Ti3GeC2, Ti3Si0.5Al0.5C2 and Ti2AlC, in the 300–1 573 K Temperature Range[J]. Acta. Mater., 2006, 54: 2 757–2 767

J Qin, D He, C Chen, et al. Phase Segregation of Titanium-Aluminium Carbide (Ti2AlC) at High Pressure and High Temperature [J]. J. Alloy. Compd., 2008, 462: L24–L 27

J Qin, D He, L Lei, et al. Differential Thermal Analysis Study of Phase Segregation of Ti2AlC under High Pressure and High Temperature [J]. J. Alloy. Compd., 2009, 476: L8–L10

L Fang, D He, C Chen, et al. Effect of Precompression on Pressure-Transmitting Efficiency of Pyrophyllite Gaskets[J]. High Pressure Res., 2007, 27: 367–374

P W Mirwald, I C Getting, G C Kennedy. Low Fristion Cell for Piston Cylinder High-Pressure Apparatus[J]. J. Geophys. Res., 1975, 80: 1 519–1 525

X H Wang, Y C Zhou. Stability and Selective Oxidation of Aluminum in Nano-Laminate Ti3AlC2 upon Heating in Ar[J]. Chem. Mater., 2003, 15: 3 716–3 720

J Emmerlich, D Music, P Ekund, et al. Thermal Stability of Ti3SiC2 Thin Films[J]. Acta. Mater., 2007, 55: 1 479–1 488

M W Barsoum, T El-Raghy, L Farber, et al. The Topotaxial Transformation of Ti3SiC2 to Form a Partially Ordered Cubic TiC0.67 Phase by the Diffusion of Si into Molten Cryolite[J]. J. Electro. Soc., 1999, 146: 3 919–3 923

J Zhang, J Y Wang, Y C Zhou. Structure Stability of Ti3AlC2 in Cu and Microstructure Evolution of Cu-Ti3AlC2 Composites[J]. Acta. Mater., 2007, 55: 4 381–4 390

J X Chen, Y C Zhou, H B Zhang, et al. Thermal Stability of Ti3AlC2/Al2O3 Composites in High Vacuum[J]. Mater. Chem. Phys., 2007, 104(1): 109–122

G Hug, M Jaouen, M W Barsoum. X-Ray Absorption Spectroscopy, EELS, and Full-Potential Augmented Plane Wave Study of the Electronic Structure of Ti2AlC, Ti2AlN, Nb2AlC, and (Ti0.5Nb0.5)2AlC[J]. Phys. Revs. B, 2005, 71: 024 105/1–024 105/12

Y Zhou, Z Sun. Electronic and Bonding Properties of Layered Machinable Ti2AlC and Ti2AlN Ceramics[J]. Phys. Revs. B, 2000, 61: 12 570–12 573

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (Nos. 50572067, 10772126)

Rights and permissions

About this article

Cite this article

An, P., He, Z., Qin, J. et al. Stability of titanium-aluminium nitride (Ti2AlN) at high pressure and high temperatures. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 914–919 (2011). https://doi.org/10.1007/s11595-011-0336-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0336-8