Abstract

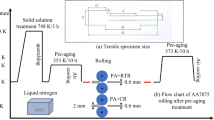

We comparatively studied the mechanical properties anisotropy, microstructure and texture of the commercial and the new developed AA6111 alloys through tensile test, optical microscopy, and XRD analysis. The results show that the anisotropy of mechanical properties for the developed AA6111 alloy is lower than that of the commercial alloy. The developed alloy possesses higher r value, lower Δr value and more uniform microstructure, compared with the commercial AA6111 alloy, indicating that the deep drawability of the developed alloy has been improved significantly. The recrystallization textures of the two alloy sheets are also different. The recrystallization texture of the commercial alloy sheet mainly includes Cube and {114}<311> orientations, while the recrystallization texture of developed alloy sheet consists of Cube, Goss and R orientations. The relationships among the deep drawabilities, microstructure and texture were discussed thereafter.

Similar content being viewed by others

References

Burger G B, Gupta A K, Jeffrey P W, et al. Microstructural Control of Aluminum Sheet Used in Automotive Applications[J]. Mater. Charact., 1995, 35(1): 23–39

Hirsch J, Al-Samman T. Superior Light Metals by Texture Engineering: Optimized Aluminum and Magnesium Alloys for Automotive Applications[J]. Acta Mater., 2013, 61(3): 818–843

Sidor J J, Petrov R H, Kestens L A I. Modeling the Crystallographic Texture Changes in Aluminum Alloys during Recrystallization[J]. Acta Mater., 2011, 59(14): 5735–5748

Engler O, Hirsch J. Texture Control by Thermomechanical Processing of AA6xxx Al-Mg-Si Sheet Alloys for Automotive Applications-a Review[J]. Mater. Sci. Eng., 2002, A336: 249–262

Sidor J, Miroux A, Petrov R, et al. Controlling the Plastic Anisotropy in Asymmetrically Rolled Aluminium Sheets[J]. Philos. Mag., 2008, 88(30-32): 3779–3792

Liu H, Song W J, Zhao G, et al. Effect of Mg on Microstructures and Properties of Al-Mg-Si-Cu Aluminium Alloys for Automotive Body Sheets[J]. Trans. Nonferrous Met. Soc. China, 2005, 15(1): 30–34

Ghosh M, Miroux A, Werkhoven R J, et al. Warm Deep-drawing and Post Drawing Analysis of Two Al-Mg-Si Alloys[J]. J. Mater. Process. Technol., 2014, 214(4): 756–766

Hu Z Q, Wan L, Wu S S, et al. Microstructure and Mechanical Properties of High Strength Die-casting Al-Mg-Si-Mn Alloy[J]. Mater. Des., 2013, 46: 451–456

Inoue H, Takasugi T. Texture Control for Improving Deep Drawability in Rolled and Annealed Aluminum Alloy Sheets[J]. Mater. Trans., 2007, 48(8): 2014–2022

Davies G. Materials for Automobile Bodies[M]. Pergamon: Oxford, 2004

Inoue H, Yamasaki T, Gottstein G, et al. Recrystallization Texture and r-value of Rolled and T4-treated Al-Mg-Si Alloy Sheets[J]. Mat. Sci. Forum, 2005, 495-497: 573–578

Sidor J, Petrov R, Kestens L. Deformation, Recrystallization and Plastic Anisotropy of Asymmetrically Rolled Aluminum Sheets[J]. Mat. Sci. Eng., 2010, A528: 413–424

Engler O, Randle V. Introduction to Texture Analysis, 2nd ed.[M]. London: CRC Press, 2009

Wu P D, Macewen S R, Lloyd D J, et al. Effect of Cube Texture on Sheet Metal Formability[J]. Mat. Sci. Eng., 2004, A364: 182–187

Jin H, Lloyd D J. Evolution of Texture in AA6111 Aluminum Alloy after Asymmetric Rolling with Various Velocity Ratios between Top and Bottom Rolls[J]. Mat. Sci. Eng., A465: 267-273

Engler O, Kim H C, Huh M Y. Formation of {111}Fibre Texture in Recrystallised Aluminium Sheet[J]. Mat. Sci.Technol., 2001, 17(1): 75–86

Singh R K, Singh A K, Prasad N E. Texture and Mechanical Property Anisotropy in an Al-Mg-Si-Cu Alloy[J]. Mat. Sci. Eng., 2000, A277: 114–122

Leu D. Prediction of the Limiting Drawing Ratio and the Maximum Drawing Load in Cup-drawing[J]. Int. J. Mach. Tool. Manu., 1997, 37(2): 201–213

Engler O, Vatne H E, Nes E. The Roles of Oriented Nucleation and Oriented Growth on Recrystallization Texture in Commercial Purity Aluminium[J]. Mat. Sci. Eng., 1996, A205: 187–198

Liu Y S, Kang S B, Ko H S. Texture and Plastic Anisotropy of Al-Mg-0.3Cu-1.0Zn Alloys[J]. Scripta Mater., 1997, 37(4): 411–417

Bung H J. Texture Analysis in Material Science[M]. London: Butterworths Press, 1982

Sidor J, Miroux A, Petrov R, et al. Microstructural and Crystallographic Aspects of Conventional and Asymmetric Rolling Processes[J]. Acta Mater., 2008, 56(11): 2495–2507

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National High Technical Research and Development Program of China (No.2013AA032403), and the National Natural Science Foundation of China (No.51571023) and Fundamental Rearch Funds for the Central Universities (No.FRFTP- 15-051A3)

Rights and permissions

About this article

Cite this article

Wang, X., Guo, M., Cao, L. et al. Relationship among mechanical properties anisotropy, microstructure and texture in AA 6111 alloy sheets. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 648–653 (2016). https://doi.org/10.1007/s11595-016-1424-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1424-6