Abstract

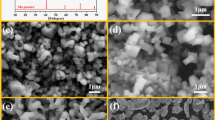

Six Ti(C,N)-TiN-WC-Co cermet materials originating from the same powder mixture but sintered to different stages of the sintering cycle have been studied using scanning electron microscopy (SEM), X-ray diffraction (XRD), transmission electron microscopy (TEM), energy-dispersive X-ray analysis (EDX), electron energy-loss spectroscopy (EELS), and energy-filtered transmission electron microscopy (EFTEM). At 1350 °C, the binder phase exists both as solid and as liquid phase. The cobalt is nanocrystalline before melting, probably due to deformation during milling. A tungsten-rich inner rim starts to form and is very inhomogeneously distributed on the Ti(C,N) cores, indicating that it is difficult to nucleate the inner rim. The outer rim mainly forms at the sintering temperature and accounts for grain growth during the holding time. There are no major variations in metal content of the carbonitride phases in the materials sintered to 1350 °C or higher, although the N/(C+N) atomic ratio changes somewhat. Close to the core-rim boundary of the materials sintered at 1430 °C, there is often an enrichment of nitrogen in the core that is believed to be the result of nitrogen diffusion from the tungsten-rich rim to the titanium-rich core during cooling.

Similar content being viewed by others

References

H. Matsubara, S.G. Shin, and T. Sakuma: Mater. Trans., 1991, vol. 32, pp. 951–56.

D.-I. Chun and D.-Y. Kim: J. Am. Ceram. Soc., 1993, vol. 76, pp. 2049–52.

J.K. Yang and H.-C. Lee: Mater. Sci. Eng. A, 1996, vol. 209, pp. 213–17.

S. Kang: Mater. Sci. Eng. A, 1996, vol. 209, pp. 306–12.

F. Qi and S. Kang: Mater. Sci. Eng. A, 1998, vol. 251, pp. 276–85.

O.N. Kaidash: Ceramics Int., 1998, vol. 24, pp. 157–62.

P. Lindahl, T. Mainert, H. Jonsson, and H.-O. andrén: J. Hard Mater., 1993, vol. 4, pp. 187–204.

P.O. Snell: Planseeberichte Pulvermetallurgie, 1974, vol. 22, pp. 91–106.

A.H. Heuer, J.S. Sears, and N.J. Zaluzec: Int. Conf. Science of Hard Materials 2, E.A. Almond, C.A. Brookes, and R. Warren, eds., Adm Hilger Ltd., Bristol, 1986, pp. 321–34.

K.G. Stjernberg: Powder Metall., 1970, vol. 13, pp. 1–12.

M.G. Gee, M.J. Reece, and B. Roebuck, J. Hard Mater., 1992, vol. 3, pp. 119–42.

W. Grogger: Ph.D. Thesis, technical University Graz, Graz, 1994.

R.D. Leapman, P. Rez, and D.F. Mayers: J. Chem. Phys., 1980, vol. 72, pp. 1232–43.

P. Rez: Ultramicroscopy, 1989, vol. 28, pp. 16–23.

J. Zackrisson, W. Grogger, F. Hofer, and H.-O. Andrén: Ultramicroscopy, 1999, vol. 79, pp. 273–81.

L. Reimer: Energy-Filtering Transmission Electron Microscopy, Springer-Verlag, Berlin, 1995.

J. Zackrisson, U. Rolander, B. Jansson, and H.-O. Andrén: Acta Mater., 2000, vol. 48, pp. 4281–91.

P. Lindahl, P. Gustafson, U. Rolander, L. Stales, and H.-O. Andrén: Int. J. Refr. Met. Hard Mater., 1999, vol. 17, pp. 411–21.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zackrisson, J., Andrén, H.O. & Rolander, U. Development of cermet microstructures during sintering. Metall Mater Trans A 32, 85–94 (2001). https://doi.org/10.1007/s11661-001-0104-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0104-z