Abstract

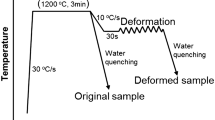

AA6022 samples were deformed at different temperatures and strain rates. Although deformation was immediately followed by quenching, as-deformed samples, especially samples subjected to higher deformation temperatures, contained a finite percentage of statically recrystallized grains. Crystallographic texture and microtexture measurements were employed to bring out developments in deformed and recrystallized microstructures and to outline the overall patterns of recrystallization. The latter was best represented through the so-called nucleation factor, an estimate of an orientation-sensitive nucleation. For a given orientation, nucleation factors were measured as the number of recrystallized grains divided by the number of deformed bands. With an increase in deformation temperatures, the dominance in nucleation appeared to have changed from cube \( \left\{ {{\text{001}}} \right\}\left\langle {{\text{100}}} \right\rangle \) to particle-stimulated nucleation (PSN) to cube again and, finally, to no preference. Relative stored-energy differences, with respect to working temperatures, explain the observed patterns in the orientation-sensitive nucleation.

Similar content being viewed by others

Notes

A similar approach can be taken for the GAM, as well, with nearly identical results. However, the GOS involves significantly less computational time. Large subgrains also exist in a warm- or hot-deformed aluminum, but those typically have a significant (above 0.75-deg) GOS or the clear presence of low-angle (a misorientation of 1 to 15 deg) boundaries.

In both cases, discrete data from the EBSD scans of deformed and recrystallized cube (within 20 deg of exact cube) were used. The large EBSD data were given appropriate rotations, so that exact orthorhombic rolling textures were obtained.

The maxima in the recrystallized cube was at 400 °C (Figure 4(b)).

It also needs to be pointed out that the AA6022 can have significant competitive grain growth at higher annealing temperatures.

References

J. Hirsch, K. Lücke: Acta Metall., 1988, vol. 36, pp. 2863–82

B. Bay, N. Hansen, D.A. Hughes, D. Kuhlmann-Wilsdorf: Acta Metall. Mater., 1992, vol. 40, pp. 205–19

C. Maurice, J.H. Driver: Acta Metall. Mater., 1993, vol. 41, pp. 1653–64

I. Samajdar, P. Ratchev, B. Verlinden, E. Aernoudt: Acta Mater., 2001, vol. 49, pp 1759–69

I.L. Dillamore, H. Katoh: Met. Sci., 1974, vol. 8, pp. 73–83

F. Basson, J.H. Driver: Acta Mater., 2000, vol. 48, pp. 2101–15

L. Delannay, O.V. Mishin, D. Juul-Jensen, P. Vann-Houtte: Acta Mater., 2001, vol. 49, pp. 2441–51

J.A. Wert, Q. Liu, N. Hansen: Acta Mater., 1997, vol. 45, pp. 2565–76

W.C. Liu, J.G. Morris: Mater. Sci. Eng., A, 2004, vol. 380, pp. 147–54

G.B. Sarma, B. Radhakrishnan: Mater. Sci. Eng., A, 2004, vol. 385, pp. 91–104

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed., Pergamon, Oxford, UK, 2002

B. Verlinden, J. Driver, I. Samajdar, R.D. Doherty: Thermo-Mechanical Processing of Metallic Materials, R.W. Cahn, ed., Elsevier, Amsterdam, 2007

J. Hjelen, R. Orsund, E. Nes: Acta Metall. Mater., 1991, vol. 39, pp. 1377–1404

D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul-Jensen, M.E. Kasnner, W.E. King, T.R. McNelley, H.J. McQueen, A.D. Rollet: Mater. Sci. Eng., A, 1997, vol. 238, pp. 219–74

B.J. Duggan, K. Lücke, G. Kohlhoff, C.S. Lee: Acta Metall. Mater., 1993, vol. 41, pp. 1921–27

D. Juul-Jensen: Acta Metall. Mater., 1995, vol. 43, pp. 4117–29

O. Engler, K. Lücke: Scripta Metall. Mater., 1992, vol. 27, pp. 1527–32

R. Sebald, G. Gottstein: Acta Mater., 2002, vol. 50, pp. 1587–98

T.J. Sabin, G. Winther, D. Juul-Jensen: Acta Mater., 2003, vol. 51, pp. 3999–4011

J. Hirsch, E. Nes, K. Lücke: Acta Metall., 1987, vol. 35, pp. 427–38

R.D. Doherty, K. Kashyap, S. Panchanadeeswaran: Acta Metall. Mater., 1993, vol. 41, pp. 3029–53

O. Daaland, E. Nes: Acta Mater., 1996, vol. 44, pp. 1413–35

H.E. Vatne, T. Furu, R. Ørsund, E. Nes: Acta Mater., 1996, vol. 44, pp. 4463–73

I. Samajdar, R.D. Doherty: Acta Mater., 1998, vol. 46, pp. 3145–58

G. Guiglionda, A. Borbely, J.H. Driver: Acta Mater., 2004, vol. 52, pp. 3413–23

I. Samajdar, B. Verlinden, L. Rabet, P. Van-Houtte: Mater. Sci. Eng., A, 1999, vol. 266, pp. 146–54

N. Rajamohan, J.A. Szpunar: Acta Mater., 2000, vol. 48, pp. 3327–40

F.J. Humphreys: Acta Metall., 1977, vol. 25, pp. 1323–44

F.J. Humphreys, P.N. Kalu: Acta Metall., 1987, vol. 35, pp. 2815–29

M.G. Ardakani, F.J. Humphreys: Acta Metall. Mater., 1994, vol. 42, pp. 763–80

R. Ørsund, E. Nes: Scripta Metall., 1988, vol. 22, pp. 671–76

I. Samajdar, L. Rabet, B. Verlinden, P. Van-Houtte: ISIJ Int., 1998, vol. 38, pp. 539–46

O. Engler, H.E. Vatne, E. Nes: Mater. Sci. Eng., A, 1996, vol. 205, pp. 187–98

D. Juul-Jensen, N. Hansen, F.J. Humphreys: Acta Metall., 1985, vol. 33, pp. 2155–62

M. Ferry, F.J. Humphreys: Acta Mater., 1996, vol. 44, pp. 3089–103

A.A. Ridha, W.B. Hutchinson: Acta Metall., 1982, vol. 30, pp. 1929–39

H. Weiland, J. Hirsch: Text. Microstruct., 1991, vols. 14–18, pp. 647–52

M.F. Ashby: Philos. Mag., 1970, vol. 21, pp. 399–424

P. Van-Houtte: Acta Metall. Mater., 1995, vol. 43, pp. 2859–79

H. Weiland, T.N. Rouns, J. Liu: Z. Metallkd., 1994, vol. 85, pp. 592–97

R.D. Doherty: Scripta Metall., 1985, vol. 19, pp. 927–30

C.M. Sellars, W.J. McG. Tegart: Int. Metall. Rev., 1972, vol. 17, pp. 1–24

T. Petterson: Doctoral Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 1999

N. Stanford, D. Dunne, M. Ferry: Mater. Sci. Eng., A, 2003, vol. 348, pp. 154–62

H. Weiland: Proc. 21st Risø Int. Symp. Mater. Sci.: Recrystallization—Fundamental Aspects and Relations to Deformation Microstructures, N. Hansen, X. Huang, D. Juul-Jensen, E.M. Lauritsen, T. Leffers, W. Pantleon, T.J. Sabin, J.A. Wert, eds., Risø National Laboratory, Roskilde, Denmark, 2000, pp. 637–43

S. Panchanadeeswaran, R.D. Doherty, R. Becker: Acta Mater., 1996, vol. 44, pp. 1233–62

P. Van-Houtte: MTM-FHM Software System, version 2, MTM, KULeuven, Belgium, 1995

H.J. Bunge: Texture Analysis in Materials Science, Butterworths, London, 1982

M.H. Alvi, S. Cheong, H. Weiland, A.D. Rollet: Mater. Sci. Forum, 2004, vols. 467–470, pp. 357–62

M.A. Alvi: Doctoral Thesis, Carnegie Mellon University, Pittsburgh, PA, 2005

T. Furu: Doctoral Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 1992

O. Engler, J. Hirsch: Mater. Sci. Eng., A, 2002, vol. 336, pp. 249–62

H. Weiland: Mater. Sci. Forum, 2004, vols. 467–470, pp. 349–56

I. Gutierrez, F.R. Castro, J.J. Urcola, M. Fuentes: Mater. Sci. Eng., A, 1988, vol. 102, pp. 77–84

R.A. Vandermeer, D. Juul-Jensen: Acta Mater., 2003, vol. 51, pp. 3005–18

G. Ibe, K. Lücke: in Recrystallisation, Grain Growth and Textures, H. Margolin, ed., ASM, Materials Park, OH, 1966, pp. 434–47

I. Samajdar, R.D. Doherty: Scripta Metall. Mater., 1995, vol. 32, pp. 845–50

J.K. Mackenzie, M.J. Thompson: Biometrica, 1957, vol. 44, pp. 205–10

Acknowledgments

The authors acknowledge the financial support received from Alcoa. The authors also acknowledge the texture and microtexture measurements from the National Facility of Orientation Imaging Microscopy and X-Ray Bulk Texture at the Indian Institute of Technology, Bombay (a Department of Science and Technology-Intensification of Research in High Priority Area (DST-IRPHA) facility).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 31, 2008.

Appendix

Appendix

Commercial microtexture programs such as the TSL advanced crystallographic technique have an ODF resolution higher than 1 deg. For the present study, a high-resolution binning of EBSD data was needed and the following procedure was adopted.

-

(a)

Data points were “visited” one by one and their intensities were estimated. The intensity, I, at a given point was obtained by counting all points within a 5-deg radius of the point. This was normalized by the average intensity, I avg, which is the sum of all the intensities divided by the total number of data points.

-

(b)

I/I avg values were tabulated for 0.2-deg intervals and respective plots and analyses (Figures 7(b) and (c) and Table III) were obtained.

It should be noted that the output typically contained more details (better resolution (Figure 7(a) vs (c) and Table I vs II) than the conventional ODF analysis.

Rights and permissions

About this article

Cite this article

Raveendra, S., Mishra, S., Mani Krishna, K. et al. Patterns of Recrystallization in Warm- and Hot-Deformed AA6022. Metall Mater Trans A 39, 2760–2771 (2008). https://doi.org/10.1007/s11661-008-9620-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9620-4