Abstract

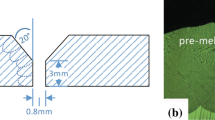

In the current study, welding of TZM (molybdenum-based alloy) plates in square-butt configuration was carried out using electron beam and laser-GTAW hybrid power sources. Microstructures of weld joint containing three zones—parent metal, heat-affected zone, and fusion zone—were clearly identified when examined through optical and scanning electron microscopy. The weld joints were found to be sound with very wide fusion and heat-affected zones. The microstructure of the fusion zone was coarse-grained. as-solidified microstructure, while the microstructure of heat-affected zone was the recrystallized microstructure with reduction in grain size as distance from the fusion line increased. Microhardness profile using Vickers hardness tester was obtained across the weld region, and the tensile properties of the weld joints were evaluated by performing room temperature tensile test and fracture was examined using scanning electron microscope. Joint coefficient of the weld joints were ~40 to 45 pct of that of the parent metals with nonmeasurable tensile ductility with predominantly transgranular mode of fracture indicating weakness along the grain boundary. Detailed orientation imaging and transmission electron microscopy were carried out to understand the most dominating factor in introducing weld joint brittleness.

Similar content being viewed by others

References

S. El-Genk Mohamed and Jean-Michel Tournier : J. Nucl. Mater., 2005, vol. 340,pp.93–112.

W.D. Klopp: Space Nuclear Power Systems, M.S. El-Genk and M.D. Hoover, eds., Orbit Book Company, Malabar, FL, 1985, vol. 42, p. 359.

L.D. Lundberg: Los Alamos Scientific Laboratory’s Report No. LA-8685-MS, Los Alamos, NM, January 1981.

V. A. Borisenko: Soviet powder metallurgy and metal ceramics, 1963, vol. 1, no. 3, pp 182.

D.R. Ervin, D.L Bourell, C. Rabenberg, L. Persad : Mater. Sci. Eng. A, 1988, vol. 102, pp. 25-30.

OD Neikov et al. (2009). Handbook of non-ferrous metal powders: technologies and applications. Elsevier, New York, pp. 464–466

J. Fan, M. Lu, H. Cheng, J. Tian, B. Huang: Int. J. Refract. Met. H., 2009, vol. 27, pp. 78-82.

F. Morito, J. Less-Common Metals, 1989, vol.146,pp 337-346.

F. Morito, J of Nucl. Mater., 1994, vol.212-215 pp. 1608-1612.

T Mrotzek, A Hoffmann, U Martin: Int. J. Refract. Met. Hard Mater., 2006, vol. 24, pp. 298-305.

B.V. Cockeram: Mater. Sci. & Engg. A, 2006, vol. 418, pp.120–136.

I. G. Sharma, S. P. Chakraborty, A. K. Suri: J. Alloy Comp., 2005, vol.393, pp.122–127.

R. W. Burman: JOM, 1977, vol 29, pp.12-17

M.H Scott, P.M Knowlson: J. Less Common Met., 1963, vol. 5, pp. 205-244.

K.-S. Wang et al: Mater. Sci Eng. A, 2015, vol.636, pp. 415-420.

R.L Kesterson: Hydrogen embrittlement testing, ASTM STP 543, ASTM 1974, pp. 254–63

H. Kurishita, Y. Kitsunai, T. Shibayama, H. Kayano, Y. Hiraoka : J. Nucl. Mater, 1996, vol. 233-237, pp. 557-564

J. Wadsworth, G. R. Morse and P. M. Chewey: Mater. Sci. Eng., 1983, vol. 59, pp. 257-273.

J Warren: Int. J. Refract. Met. H., 1998, vol. 16, pp 149-157.

M.K Miller, E.A Kenika, M.S. Mousa, 1, K.F Russell, A.J Bryhan : Scripta Mater, 2002, vol.46,pp.299–303

M P Seah: J. Phys. F: Met. Phys. 1980,vol.10,pp.1043-64.

F L Carr, M Goldman, L D Jaffe and D C. Buffum : Trans. AIME. 1953, vol.197, pp. 998

B. V. Cockeram: Metall. Trans., 2002, vol. 33A, pp. 3685-707

G. Neumann and C. Tuijn: Self diffusion and impurity diffusion in pure metals: handbook of experimental data. Pregaman Metals Series, vol. 14. Elsevier, Oxford, U.K.

C. Thiel,, R. Weber, J. Johannsen, T. Graf : Physics Procedia, 2013, vol. 41,pp. 209–215;

Z. Sun, R. Karppi: J. of Mater Process Tech., 1966, vol. 59, pp. 257-267.

R. H. Lamoreaux: Bull. Alloy Phase Diag, 1980,vol. 1, pp. 85-89.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 22, 2015.

Rights and permissions

About this article

Cite this article

Chatterjee, A., Kumar, S., Tewari, R. et al. Welding of Mo-Based Alloy Using Electron Beam and Laser-GTAW Hybrid Welding Techniques. Metall Mater Trans A 47, 1143–1152 (2016). https://doi.org/10.1007/s11661-015-3267-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3267-8