Abstract

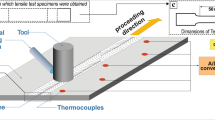

In the present work, the effect of friction stir processing parameters on the mechanical properties of an interstitial free steel was studied. Four rotating speeds (800, 1250, 1600, 2000 rpm) and two traverse speeds (31.5 and 63 mm/min) were employed. On both sides of specimens, a nanograin layer with the thickness and nanograins of 150 μm and 50-100 nm were formed, respectively. For the specimen processed at rotating speed of 1600 rpm and the traverse speed of 31.5 mm/min, the maximum strength was achieved, which was about 80% increase in the strength comparing to that of base material. For constant traverse speed, the increase in the rotation speed from 800 to 1600 rpm led to a decrease in uniform and total elongation of friction stir processed samples. By contrast, when the rotating speed exceeded 1600 rpm, the uniform and total elongation was increased again, while there was a drop in strength. The results of microhardness indicate more than threefold increase in the hardness of the stirred zone comparing to that of base material.

Similar content being viewed by others

References

C.C. Koch, D.G. Morris, K. Lu, and A. Inoue, Ductility of Nanostructured Materials, Mater. Res. Soc. Bull., 1999, 24, p 54–58

S.X. McFadden, R.S. Mishra, R.Z. Valiev, A.P. Zhilyaev, and A.K. Mukherjee, Low-Temperature Superplasticity in Nanostructured Nickel and Metal Alloys, Nature, 1999, 398, p 684

K. Ramesh, K. Guduru, L. Murty, K. Youssef, R. Scattergood, and C. Koch, Mechanical Behavior of Nanocrystalline Copper, Mater. Sci. Eng., A, 2007, 463, p 14–21

S. Cheng, E. Ma, Y.M. Wang, L.J. Kecskes, K.M. Youssef, C.C. Koch, U.P. Trociewitz, and K. Han, Tensile Properties of In Situ Consolidated Nanocrystalline Cu, Acta Mater., 2005, 53, p 1521–1533

D. Jia, K.T. Ramesh, and E. Ma, Effects of Nanocrystalline and Ultrafine Grain Sizes on Constitutive Behavior and Shear Bands in Iron, Acta Mater., 2003, 51, p 3495–3509

A. Azushima, Trend of Ultrafine Grained Steel, Proceedings of the 245th Symposium on Technology of Plasticity, 2003, p 225, 53–60 (in Japanese)

Z.Y. Maa, F.C. Liu a, and R.S. Mishra, Superplastic Deformation Mechanism of an Ultrafine-Grained Aluminum Alloy Produced by Friction Stir Processing, Acta Mater., 2010, 58, p 4693–4704

B. Hadzima, M. Janeˇcek, Y. Estrin, and H. Kim, Microstructure and Corrosion Properties of Ultrafine-Grained Interstitial Free Steel, Mater. Sci. Eng., A, 2007, 462, p 243–247

S. Han, M. Goto, C. Lim, C. Kima, and S. Kim, Fatigue Behavior of Nano-grained Copper Prepared by ECAP, J. Alloys Compd., 2007, 434–435, p 304–306

Z.Y. Ma, S.R. Sharma, and R.S. Mishra, Effect of Multiple-Pass Friction Stir Processing on Microstructure and Tensile Properties of a Cast Aluminum-Silicon Alloy, Scripta Mater., 2006, 54, p 1623–1626

K. Nakata, Y.G. Kim, H. Fujii, T. Tsumura, and T. Komazaki, Improvement of Mechanical Properties of aluminum Die Casting Alloy by Multi-Pass Friction Stir Processing, Mater. Sci. Eng., A, 2006, 437, p 274–280

L. Karthikeyan, V.S. Senthilkumar, V. Balasubramanian, and S. Natarajan, Mechanical Property and Microstructural Changes During Friction Stir Processing of Cast Aluminum 2285 Alloy, Mater. Des., 2009, 30, p 2237–2242

A.H. Feng and Z.Y. Ma, Enhanced Mechanical Properties of Mg-Al-Zn Cast Alloy Via Friction Stir Processing, Scripta Mater., 2007, 56, p 397–400

Rajib Saha and R.K. Ray, Formation of Nano- to Ultrafine Grains in a Severely Cold Rolled Interstitial Free Steel, Mater. Sci. Eng., A, 2007, 459, p 223–226

H. Fujii, L. Cui, N. Tsuji, M. Maeda, K. Nakata, and K. Nogi, Friction Stir Welding of Carbon Steels, Mater. Sci. Eng., A, 2006, 429, p 50–57

H. Fujii, R. Ueji, Y. Takada, H. Kitahara, N. Tsuji, K. Nakata, and K. Nogi, Friction Stir Welding of Ultrafine Grained Interstitial Free Steels, Mater. Trans., 2006, 47, p 239–242

K. Dehghani and A. Chabok, Dependence of Zener Parameter on the Nanograins Formed During Friction Stir Processing of Interstitial Free Steels, Mater. Sci. Eng., A, 2011, 528, p 4325–4330

G. Dieter, Mechanical Metallurgy, McGraw-Hill Book Company, New York, 1986

E. Hosseini and M. Kazeminezhad, Nanostructure and Mechanical Properties of 0-7 Strained Aluminum by CGP: XRD, TEM and Tensile Test, Mater. Sci. Eng., A, 2009, 526, p 219–224

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Constrained Groove Pressing of Low Carbon Steel: Nano-structure and Mechanical Properties, Mater. Sci. Eng., A, 2010, 527, p 4043–4049

R.Z. Valiev, A.V. Korznikov, and R.R. Mulyukov, Microstructure and Mechanical Properties of Ultrafine Grained Copper Processes by Multiple Isothermal Forging, Phys. Met. Metall., 1992, 73, p 373

H.Q. Li and F. Ebrahimi, Transition of Deformation and Fracture Behaviors in Nanostructured Face-Centered-Cubic Metals, Appl. Phys. Lett., 2004, 84, p 4307–4309

M.A. Meyers, A. Mishra, and D.J. Benson, Mechanical Properties of Nanocrystalline Materials, Prog. Mater. Sci., 2006, 51, p 427–556

X. Zhang, H. Wang, R.O. Scattergood, J. Narayan, and C.C. Koch, Mechanical Properties of Cyromilled Nanocrystalline Zn Studied by the Miniaturized Disk Bend Test, Acta Mater., 2002, 50, p 3527–3533

X. Zhang, H. Wang, R. Scattergood, J. Narayan, C. Koch, and A. Sergueeva, Studies of Deformation Mechanisms in Ultra-fine-grained and Nanostructured Zn, Acta Mater., 2002, 50, p 4823–4830

Y. Wang and E. Ma, Three Strategies to Achieve Uniform Tensile Deformation in a Nanostructured Metal, Acta Mater., 2004, 52(6), p p1699–p1709

M. Dao, L. Lu, R.J. Asaro, J.T.M. De Hosson, and E. Ma, Toward a Quantitative Understanding of Mechanical Behavior of Nanocrystalline Metals, Acta Mater., 2007, 55, p 4041–4065

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chabok, A., Dehghani, K. Effect of Processing Parameters on the Mechanical Properties of Interstitial Free Steel Subjected to Friction Stir Processing. J. of Materi Eng and Perform 22, 1324–1330 (2013). https://doi.org/10.1007/s11665-012-0424-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0424-8