Abstract

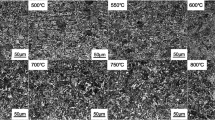

Mechanical trimming process for ultra-high strength boron steel after hot stamping was carried out in this study. Shear and tensile tests were designed to analyze the influences of stress state on the fracture mode; trimmed fracture surface and profile were observed and compared to other commonly used steels such as DP980 and Q235 etc.; the crack propagation during trimming process was studied through step-by-step tests. The observation and analysis reveal that the fracture mode of hot-stamped boron steel is highly related to the stress state, it belongs to cleavage fracture on low stress triaxiality but dimple fracture on high stress triaxiality. Such phenomenon is reflected in the trimming process, during which the stress state changes from shear-dominated state to tensile-dominated state. In addition, the burnish zone of trimmed boron steel is much smaller than other high strength steels, and the profile of cutting surface shows an ‘S’-like shape which is destructive to the trimming tool. Moreover, during the trimming process, most martensite laths near the cutting edge are stretched and rotated markedly to the direction of the shear band, and the main crack expands along those grain boundaries, which may penetrate through a few martensite laths and form small crack branches.

Similar content being viewed by others

References

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 2103–2118

X. Han, Y. Zhong, K. Yang et al., Application of Hot Stamping Process by Integrating Quenching & Partitioning Heat Treatment to Improve Mechanical Properties, Proc. Eng., 2014, 81, p 1737–1743

J. Chen, X. Li, and X. Han, Hot Stamping, Elsevier Ltd., Amsterdam, 2014, p 351–370

P. Åkerström, Modelling and Simulation of Hot Stamping, Luleå University of Technology, Department of Applied Physics and Mechanical Engineering, Luleå, 2006

M. Merklein, J. Lechler, and M. Geiger, Characterisation of the Flow Properties of the Quenchenable Ultra High Strength Steel 22MnB5, Ann. CIRP, 2006, 55(1), p 229–236

P.X. Liu, Y.S. Zhang, H.Q. Liu et al., Modeling for Periodic Striation and Microstructure Evolution in Active Gas Melt Laser Cutting for Phase Hardened Parts, Int. J. Adv. Manuf. Technol., 2014, 70(5–8), p 1421–1426

M. Rossini, P.R. Spena, L. Cortese et al., Investigation on Dissimilar Laser Welding of Advanced High Strength Steel Sheets for the Automotive Industry, Mater. Sci. Eng. A, 2015, 628, p 288–296

K.-I. Mori, T. Maeno, and Y. Maruo, Punching of Small Hole of Die-Quenched Steel Sheets Using Local Resistance Heating, CIRP Ann. Manuf. Technol., 2012, 61(1), p 255–258

A. Lara, I. Picas, and D. Casellas, Effect of the Cutting Process on the Fatigue Behaviour of Press Hardened and High Strength Dual Phase Steels, J. Mater. Process. Technol., 2013, 213(11), p 1908–1919

H. So, D. Fassmann, H. Hoffmann et al., An Investigation of the Blanking Process of the Quenchable Boron Alloyed Steel 22MnB5 Before and After Hot Stamping Process, J. Mater. Process. Technol., 2012, 212(2), p 437–449

H.-S. Choi, B.-M. Kim, D.-H. Kim et al., Application of Mechanical Trimming to Hot Stamped 22MnB5 Parts for Energy Saving, Int. J. Presicion Eng. Manuf., 2014, 15(6), p 1087–1093

A. Horling, L. Hultman, M. Oden et al., Mechanical Properties and Machining Performance of Ti1-xAlxN-Coated Cutting Tools, Surf. Coat. Technol., 2005, 191(2–3), p 384–392

A. Ghiotti, S. Bruschi, and D. Pellegrini, Influence of Die Materials on the Microstructural Evolution of HSS Sheets in Hot Stamping, Trans Tech Publications Ltd, Stafa-Zurich, 2011, p 201–208

I. Picas, R. Hernández, D. Casellas et al. Tool Performance in Cutting of Hot Stamped Steels. 1st International Conference on Hot Sheet Metal Forming of High-Performance Steel, 2008, p 179–189

V. Savic, L.G. Hector. Tensile Deformation and Fracture of Press Hardened Boron Steel Using Digital Image Correlation. SAE Technical Paper, 2007

G. Avramovic-Cingara, Y. Ososkov, M. Jain et al., Effect of Martensite Distribution on Damage Behaviour in DP600 Dual Phase Steels, Mater. Sci. Eng., 2009, 516(1), p 7–16

S.Q. Zhang, Y.H. Huang, B.T. Sun et al., Effect of Nb on Hydrogen-Induced Delayed Fracture in High Strength Hot Stamping Steels, Mater. Sci. Eng. A, 2015, 626, p 136–143

Y. Bao, Dependence of Ductile Crack Formation in Tensile Tests on Stress Triaxiality, Stress and Strain Ratios, Eng. Fracture Mech., 2005, 72, p 505–522

D.C. Wen, Erosion and Wear Behavior of Nitrocarburized DC53 Tool Steel, Wear, 2010, 268(3–4), p 629–636

C. Hubert, L. Dubar, M. Dubar et al., Experimental Simulation of Strip Edge Cracking in Steel Rolling Sequences, J. Mater. Process. Technol., 2010, 210, p 1587–1597

Y. Sun, X. Li, X. Yu et al., Fracture Morphologies of Advanced High Strength Steel During Deformation, Acta Metallurg. Sinica (English Letters), 2014, 27(1), p 101–106

Acknowledgments

The authors are pleased to acknowledge the support of this work by the National Natural Science Foundation of China through contract/Grant Number 51105247.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, X., Yang, K., Chen, S. et al. Fracture Profile and Crack Propagation of Ultra-High Strength Hot-Stamped Boron Steel During Mechanical Trimming Process. J. of Materi Eng and Perform 24, 3845–3851 (2015). https://doi.org/10.1007/s11665-015-1690-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1690-z