Abstract

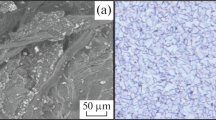

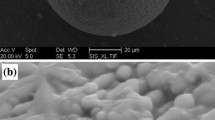

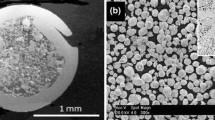

Flame-sprayed coatings are widely used in the industries attributed to their low cost and simple processing. However, the presence of porosity and poor adhesion with the substrate requires suitable post-processing of the as-sprayed deposits. In the present work, post-processing of the flame-sprayed Ni-based coating has been successfully attempted using microwave hybrid heating. Microwave post-processing of the flame-sprayed coatings was carried out at 2.45 GHz in a 1 kW multimode industrial microwave applicator. The microwave-processed and as-sprayed deposits were characterized for their microstructure, porosity, fracture toughness and surface roughness. The properties of the coatings were correlated with their abrasive wear behavior using a sliding abrasion test on a pin-on-disk tribometer. Microwave post-processing led to healed micropores and microcracks, thus causing homogenization of the microstructure in the coating layer. Therefore, microwave post-processed coating layer exhibits improved mechanical and tribological properties compared to the as-sprayed coating layer.

Similar content being viewed by others

References

R. Asthana, A. Kumar, and N.B. Dahotre, Materials Processing and Manufacturing Science, 1st ed., Butterworth-Heinemann, Oxford, 2006, p 313–396

P. Farahmand, S. Liu, Z. Zhang, and R. Kovacevic, Laser Cladding Assisted by Induction Heating of Ni–WC Composite enhanced by nano-WC and La2O3, Ceram. Int., 2014, 40, p 15421–15438

P.W. Leech, X.S. Li, and N. Alam, Comparison of Abrasive Wear of a Complex High Alloy Hardfacing Deposit and WC–Ni based Metal Matrix Composite, Wear, 2012, 294–295, p 380–386

H. Skulev, S. Malinov, P.A. Basheer, and W. Sha, Modifications of Phases, Microstructure and Hardness of Ni-Based Alloy Plasma Coatings Due to Thermal Treatment, Surf. Coatings Technol., 2004, 185, p 18–29

D. Gupta and A.K. Sharma, Microstructural Characterization of Cermet Cladding Developed Through Microwave Irradiation, J. Mater. Eng. Perform., 2012, 21, p 2165–2172

R. González, M. Cadenas, R. Fernández, J.L. Cortizo, and E. Rodríguez, Wear Behaviour of Flame Sprayed NiCrBSi Coating Remelted by Flame or by Laser, Wear, 2007, 262, p 301–307

M. Afzal, M. Ajmal, A.N. Khan, A. Hussain, and R. Akhter, Surface Modification of Air Plasma Spraying WC–12% Co Cermet Coating by Laser Melting Technique, Opt. Laser Technol., 2014, 56, p 202–206

B.S. Sidhu, D. Puri, and S. Prakash, Mechanical and Metallurgical Properties of Plasma Sprayed and Laser Remelted Ni–20Cr and Stellite-6 Coatings, J. Mater. Process. Technol., 2005, 159, p 347–355

J. Mateos, J.M. Cuetos, E. Fernández, and R. Vijande, Tribological Behaviour of Plasma-Sprayed WC Coatings With and Without Laser Remelting, Wear, 2000, 239, p 274–281

X. Guozhi, Z. Jingxian, L. Yijun, W. Keyu, M. Xiangyin, and L. Pinghua, Effect of Laser Remelting on Corrosion Behavior of Plasma-Sprayed Ni-Coated WC Coatings, Mater. Sci. Eng. A, 2007, 460, p 351–356

R. Shoja-Razavi, Laser Surface Treatment of Stellite 6 Coating Deposited by HVOF on 316L Alloy, J. Mater. Eng. Perform., 2016, 25, p 2583–2595

Y.M. Zhang, M. Hida, A. Sakakibara, and Y. Takemoto, Influence of WC Addition on Microstructures of Laser-Melted Ni-Based Alloy Coating, J. Mater. Eng. Perform., 2002, 11, p 667–674

B.M. Dhakar, D.K. Dwivedi, and S.P. Sharma, Studies on Remelting of Tungsten Carbide and Rare Earth Modified Nickel Base Alloy Composite Coating, Surf. Eng., 2012, 28, p 73–80

Q. Wang, L. Li, G. Yang, X. Zhao, and Z. Ding, Influence of Heat Treatment on the Microstructure and Performance of High-Velocity Oxy-FUEL SPRAYED WC—12Co Coatings, Surf. Coat. Technol., 2012, 206, p 4000–4010

J.K.N. Murthy, D.S. Rao, and B. Venkataraman, Effect of Grinding on the Erosion Behaviour of a WC–Co–Cr Coating deposited by HVOF and Detonation Gun Spray Processes, Wear, 2001, 249, p 592–600

A.K. Sharma, S. Aravindhan, and R. Krishnamurthy, Microwave Glazing of Alumina—Titania Ceramic Composite Coatings, Mater. Lett., 2001, 50, p 295–301

R.R. Mishra and A.K. Sharma, Microwave-material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing, Compos. Part A Appl. Sci. Manuf., 2015, 81, p 78–97

M. Oghbaei and O. Mirzaee, Microwave versus Conventional Sintering: A Review of Fundamentals, Advantages and Applications, J. Alloys Compd., 2010, 494, p 175–189

E.T. Thostenson and T.-W. Chou, Microwave Processing: Fundamentals and Applications, Compos. Part A Appl. Sci. Manuf., 1999, 30, p 1055–1071

M.S. Srinath, A.K. Sharma, and P. Kumar, A New Approach to Joining of Bulk Copper using Microwave Energy, Mater. Des., 2011, 32, p 2685–2694

A. Bansal, A.K. Sharma, P. Kumar, and S. Das, Characterization of Bulk Stainless Steel Joints Developed Through Microwave Hybrid Heating, Mater. Charact., 2014, 91, p 34–41

D. Gupta and A.K. Sharma, Microwave cladding: A New Approach in Surface Engineering, J. Manuf. Process., 2014, 16, p 176–182

S. Zafar and A.K. Sharma, Development and Characterisations of WC–12Co Microwave Clad, Mater. Charact., 2014, 96, p 241–248

S. Zafar and A.K. Sharma, Investigations on Flexural Performance and Residual Stresses in Nanometric WC-12Co Microwave Clads, Surf. Coat. Technol., 2016, 291, p 413–422

A. Bansal, S. Zafar, and A.K. Sharma, Microstructure and Abrasive Wear Performance of Ni-Wc Composite Microwave Clad, J. Mater. Eng. Perform., 2015, 24, p 3708–3716

S. Zafar and A.K. Sharma, Structure-Property Correlations in Nanostructured WC–12Co Microwave Clad, Appl. Surf. Sci., 2016, 370, p 92–101

A.G. Evans and T.R. Wilshaw, Quasi-static Solid Particle Damage in Brittle Solids—I, Observations Analysis and Implications, Acta Metall., 1976, 24, p 939–956

H.S. Grewal, H. Singh, and A. Agrawal, Microstructural and Mechanical Characterization of Thermal Sprayed Nickel-Alumina Composite Coatings, Surf. Coat. Technol., 2013, 216, p 78–92

S. Singh, D. Gupta, and V. Jain, Recent Applications of Microwaves in Materials Joining and Surface Coatings, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2015, 230, p 603–617

K. Holmberg and A. Mathews, Coatings Tribology: A Concept, Critical Aspects and Future Directions, Thin Solid Films, 1994, 253, p 173–178

I.M. Hutchings, Tribology, Friction and Wear of Engineering Materials, 1st ed., Butterworth-Heinemann, Oxford, 1992

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zafar, S., Sharma, A.K. Microstructure and Mechanical Properties of Microwave Post-processed Ni Coating. J. of Materi Eng and Perform 26, 1382–1390 (2017). https://doi.org/10.1007/s11665-017-2540-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2540-y