Abstract

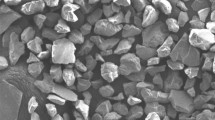

The detonation spraying is one of the most promising thermal spray variants for depositing wear and corrosion resistant coatings. The ceramic (Al2O3), metallic (Ni-20 wt%Cr) , and cermets (WC-12 wt%Co) powders that are commercially available were separated into coarser and finer size ranges with relatively narrow size distribution by employing centrifugal air classifier. The coatings were deposited using detonation spray technique. The effect of particle size and its distribution on the coating properties were examined. The surface roughness and porosity increased with increasing powder particle size for all the coatings consistently. The feedstock size was also found to influence the phase composition of Al2O3 and WC-Co coatings; however does not influence the phase composition of Ni-Cr coatings. The associated phase change and %porosity of the coatings imparted considerable variation in the coating hardness, fracture toughness, and wear properties. The fine and narrow size range WC-Co coating exhibited superior wear resistance. The coarse and narrow size distribution Al2O3 coating exhibited better performance under abrasion and sliding wear modes however under erosion wear mode the as-received Al2O3 coating exhibited better performance. In the case of metallic (Ni-Cr) coatings, the coatings deposited using coarser powder exhibited marginally lower-wear rate under abrasion and sliding wear modes. However, under erosion wear mode, the coating deposited using finer particle size exhibited considerably lower-wear rate.

Similar content being viewed by others

References

Rhys-Jones T.N. (1990) Thermally Sprayed Coating System for Surface Protection and Clearance Control Applications in Aero-Engines, Surf. Cat. Technol. 43-44:402-41

Guest C.J.S. (1986) Plasma and Detonation Gun Coatings. Trans IMF 64:33-38

Li C.J., Ohmori A. (1996) The Lamellar Structure of Detonation Gun Sprayed Al2O3 Coating. Surf. Cat. Technol. 82:254-258

Tucker R.C. Jr. (1974) Structure Property Relationships in Deposits Produced by Plasma Spray and Detonation Gun Techniques. J. Vac. Sci. Technol. 11(4):725-734

Berget J., Bardal E., Ronge T. (1998) Effect of Matrix Composition and Particle Size on Structure and Erosion-Corrosion Resistance of HVOF Sprayed WC-Co-Cr Coatings. In: Sudarshan T.S., Jeandin M., Khor K.A. (eds) Surface Modification Technologies XI. The Institute of Materials, London, p 501-515

J. Berget, E. Bardal, and T. Ronge, Effects of Powder Composition on the Erosion, Corrosion and Erosion-Corrosion Properties of HVOF Sprayed WC Based Coatings, Thermal Spray: Meeting the challenges of the 21st century, C. Coddet, Ed. (Nice, France), ASM International, 1998, p 305

Li Chang-Jiu, Li Wen-Ya (2002) Effect of Sprayed Powder Particle Size on the Oxidation behavior of MCrAlY Materials during High Velocity Oxygen-Fuel Deposition. Surf. Coat. Technol. 162:31-41

Cheang P., Khor K.A. (1996) Influence of Powder Characteristics on Plasma Sprayed Hydroxyapatite Coatings. J. Thermal. Spray Technol. 5:310-316

Kadyrov V., Margarita Yakovlev, Sen D., Srinivasa Rao D., Rao K.P., Saibaba A.V. (1993) Detonation Coating Process. Trans. PMAI 20:1-5

Saravanan P., Selvarajan V., Rao D.S., Joshi S.V., Sundararajan G. (2000) Influence of Process Variables on the Quality of Detonation Sprayed Alumina Coatings. Surf. Coat. Technol. 123:44-54

G. Sundararajan, G. Sivakumar, and D. Srinivasa Rao, The Interrelationship between Particle Velocity and Temperature, Splat Formation and Deposition Efficiency in Detonation Sprayed Alumina Coating, Thermal Spray 2001: New Surfaces for New Millennium. C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28-30, 2001 (Singapore), ASM International, 2001, p 849

G. Sivakumar, L. Ramakrishna, V. Jain, D. Srinivasa Rao, G. Sundararajan, and G. Madhusudhan Reddy, The Influence of the Process Parameters on the Properties of Detonation Sprayed WC-12%Co Coatings, Thermalspray 2001: New Surfaces for New Millennium, C.C. Berndt, K.A. Khor, E.F. Lugscheider, Ed., May 28-30, 2001 (Singapore), ASM International, 2001, p 1031

Evans A.G., Charles E.A. (1976) Fracture Toughness Determined by Indentation. J. Am. Cem. Soc. 59:371-372

K.R.C. Somaraju, D. Srnivasarao, G. Sivakumar, D. Sen, G.V.N. Rao, and G. Sundararajan, The Influence of Powder Characteristics on the Properties of Detonation Sprayed Cr3C2−25NiCr Coatings, Thermal Spray: Surface Engineering via Applied Research, C.C. Berndt, Ed. (Montreal Quebec Canada), ASM International, 2000, p 309

Arensburger D.S., Zimakov S.M., Kulu P.A., Oyaviir M.A. (2001) Coatings Deposited by the High-Velocity Flame Spraying Method. Pow. Met. Metal Cerms. 40:127-134

McPherson R. (1980) On the Formation of Thermally Sprayed Alumina Coatings. J. Mat. Sci. 15:3141-3149

Gao Y., Xu X., Yan Z., Xin G. (2002) High Hardness Alumina Coatings Prepared by Low Power Plasma Spraying. Sur. Coat. Technol. 154:189-193

McPherson R. (1973) Formation of Metastable Phases in Flame and Plasma-Prepared Alumina. J. Mat. Sci. 8:851-858

Kulkarni A., Gutleber J., Sampath S., Goland A., Lindquist W.B., Herman H., Allen A.J., Dowd B. (2004) Studies of the Microstructure and Properties of Dense Ceramic Coatings Produced by High-Velocity Oxygen-Fuel Combustion Spraying. Mat. Sci. Eng., A 369:124-137

Nolan D., Mercer P., Samandi M. (1998) Microstructural Stability of Thermal Sprayed WC-Co Composite Coatings in Oxidizing Atmospheres at 450°C. Sur. Eng. 14:124-128

R. Schwetzke and H. Kreye, Microstructure and Properties of Tungsten Carbide Coatings Sprayed with Various HVOF Spray Systems, Thermal Spray: Meeting the Challenges of the 21st Century, C. Coddet, Ed., May 25-29, (Nice, France), ASM International, 1998, p 187

T. Kraak, W. Herlaar, J. Wolke, K. De Groot, and E.A. Hyduk Jr., Influence of Different Gases on the Mechanical and Physical Properties on HVOF Sprayed Tungsten Carbide Cobalt, Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., May 25-June 5, 1992 (Orlando, FL), ASM International, 1998, p 153

Ramanath V., Jayaraman N. (1989) Characterization and Wear Performance of Plasma Sprayed WC-Co Coatings, Mat. Sci. Tech. 5:382-388

Li C.J., Ohmori A., Harada Y. (1996) Effect of Powder Structure on the Structure of Thermal Sprayed WC-Co Coatings. J. Mat. Sci. 31: 785-794

Sundararajan T., Kuroda S., Abe F., Sodeoka S. (2005) Effect of Thermal Cycling on the Adhesive Strength of Ni-Cr Coatings. Surf. Coat. Technol. 194:290-299

Rama Krishna L., Sen D., Rao Y.S., Narasimha Rao G.V., Sundararajan G. (2002) Thermal Spray Coating of Aluminum Nitride Utilizing the Detonation Spray Technique. J. Mater. Res. 17(10):2514-2523

Nakamura T., Qian G., Berndt C.C. (2000) Effects of Pores on Mechanical Properties of Plasma-Sprayed Ceramic Coatings. J. Am. Ceram. Soc. 83 (3):578-584

Luo J., Stevens R. (1999) Porosity-Dependence of Elastic Moduli and Hardness of 3Y-TZP Ceramics. Crem. Inter. 25:281-286

Verdon C., Karimi A., Martin J.L. (1997) Microstructural and Analytical Study of Thermally Sprayed WC-Co Coatings in Connection with their Wear Resistance. Mat. Sci. Eng A 234-236:731-734

Roebuck B., Almond E.A. (1988) Deformation and Fracture Processes and the Physical Metallurgy of WC-Co Hardmetals. Int. Mat. Revs. 33(2):90-110

Acknowledgments

The authors are grateful to Centre for Engineered Coatings Group for assisting in generation of the coated specimens and also to Material Characterization Group for kind assistance. The authors also thank the reviewers of this paper for their constructive comments which have certainly improved the quality.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suresh Babu, P., Rao, D.S., Rao, G.V.N. et al. Effect of Feedstock Size and its Distribution on the Properties of Detonation Sprayed Coatings. J Therm Spray Tech 16, 281–290 (2007). https://doi.org/10.1007/s11666-007-9032-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9032-9