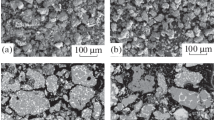

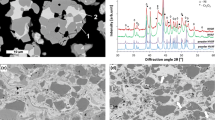

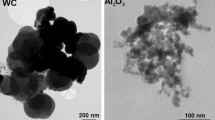

For the promising erosion and oxidation resistance of carbide cermet coating, Cr39Ni7C cermet coatings were deposited by Diamond Jet spray process using a commercial Sulzer Metco 5241 powder in this study. The microstructure, phase compositions, and high-temperature oxidation behavior of the deposited coatings were investigated. The speed and temperature of in-flight particles were measured by DPV-2000. The results revealed that the speed of in-flight particles decreased from 229 to 150 m/s with the increasing of the spraying distance from 100 to 300 mm, whereas the average temperature of in-flight particles increased from 1926 to 2245 K. The decarburization of Cr3C2 increased with the increasing of the fuel gas flow from 58 SLPM to 77 SLPM for higher heat enthalpy of the flame. Due to the formation of Cr2O3 on/in the coatings at high temperature, the sprayed coatings had good oxidation resistance at 1073 K in an air atmosphere. The oxidation behavior was found to be governed by the parabolic rate law. For the lower porosity of the coating deposited under the spraying distance of 150 mm, its oxidation resistance was better than that of the coating sprayed at the spraying distance of 200 mm. A slight reduction of sprayed Cr39Ni7C cermet coating in micro hardness occurred after high temperature at 723 K and 1073 K high-temperature oxidation.

Similar content being viewed by others

References

S. Wirojanupatump, P.H. Shipway, D.G. McCartney, The Influence of HVOF Powder Feedstock Characteristics on the Abrasive Wear Behaviour of CrxCy-NiCr Coatings, Wear, Vol 249, 2001, p. 829-837

M.H. Staia, T. Valente, C. Bartuli, D.B. Lewis, C.P. Constable, Part I: Characterization of Cr3C2-25%NiCr Reactive Plasma Sprayed Coatings Produced at Different Pressures, Surf. Coat. Technol., Vol 146-147, 2001, p. 553-562

M.H. Staia, T. Valente, C. Bartuli, D.B. Lewis, C.P. Constable, A. Romand, J. Lesage, D. Chicot, G. Mesmacque, Part II: Tribological Performance of Cr3C2-25%NiCr Reactive Plasma Sprayed Coatings Deposited at Different Pressures, Surf. Coat. Technol., Vol 146-147, 2001, p. 563-570

M. Mohanty, R.W. Smith, M. De Bonte, L.P. Celis, E. Lugscheider, Sliding Wear Behaviour of Thermally Sprayed 75/25 Cr3C2/NiCr Wear Resistant Coatings, Wear, Vol 198, 1996, p. 251-266

G.Z. Xie, Y.J. Lu, Z.Y. He, B. Hu, K.Y Wang, X.Y Mo, Y.P. Wu, P.H Lin, Microstructure and Corrosion Properties of Plasma-Sprayed NiCr-Cr3C2 Coatings Comparison with Different Post Treatment, Surf. Coat. Technol., Vol 202, 2008, p. 2885-2890

K.J. Stein, B.S. Schorr, A.R. Marder, Erosion of Thermal Spray MCr-CrC Cermet Coatings, Wear, Vol 224, 1999, p. 153-159

B.Q. Wang, A. Verstak, Elevated Temperature Erosion of HVOF Cr3C2/TiC-NiCrMo Cermet Coating, Wear,Vol 233-235, 1999, p. 342-351

J. Wang, L. Zhang, B.D. Sun, Y.H Zhou, Study of the Cr3C2-NiCr Detonation Spray Coating, Surf. Coat. Technol., Vol 130, 2000, p. 69-73

Y. Ishikawa, S. Kuroda, J. Kawakita, Y. Sakamoto, M. Takaya, Sliding Wear Properties of HVOF Sprayed WC-20%Cr3C2-7%Ni Cermet Coatings, Surf. Coat. Technol., Vol 201, 2007, p. 4718-4727

D. Toma, W. Brandl, G. Marginean, Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings, Surf. Coat. Technol., Vol 138 2001, p. 149-158

X.M. Li, Y.Y. Yang, T.M. Shao, Y.S. Jin, G. Barbezat, Impact Wear Performance of Cr3C2-NiCr Coatings by Plasma and HVOF Spraying, Wear, Vol 202, 1997, p. 208-214

N. Espallargas, J. Berget, J.M. Guilemany, A.V. Benedetti, P.H. Suegama, Cr3C2-NiCr and WC-Ni Thermal Spray Coatings as Alternatives to Hard Chromium for Erosion-Corrosion Resistance, Surf. Coat. Technol., Vol. 202 (2008) 1405-1417

G.C. Ji, C.J. Li, Y.Y. Wang, W.Y. Li, Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2-NiCr Coating, Surf. Coat. Technol., Vol 200, 2006, p. 6749-6757

C.J. Li, Y.Y. Wang, T. Wu, G.C. Ji, A. Ohmori, Effect of Types of Ceramic Materials in Aggregated Powder on the Adhesive Strength of High Velocity Oxy-Fuel Sprayed Cermet Coatings, Surf. Coat. Technol., Vol 145, 2001, p. 113-120

C.J. Li, G.C. Ji, Y.Y. Wang, K. Sonoya, Dominant Effect of Carbide Rebounding on the Carbon Loss During High Velocity Oxy-Fuel Spraying of Cr3C2-NiCr, Thin Solid Films, Vol 419, 2002, p. 137-143

T.S. Sidhu, S. Prakash, R.D. Agrawal, Hot Corrosion Studies of HVOF Sprayed Cr3C2-NiCr and Ni-20Cr Coatings on Nickel-Based Superalloy at 900°C, Surf. Coat. Technol., Vol 201, 2006, p. 792-800

J.K.N. Murthy, B. Venkataraman, Abrasive Wear Behaviour of WC-CoCr and Cr3C2-20(NiCr) Deposited by HVOF and Detonation Spray Processes, Surf. Coat. Technol., Vol 200, 2006, p. 2642-2652

http://www.freepatentsonline.com/20060040125.html, “Piston Ring and Thermal Spray Coating Used Therein, and Method for Manufacturing Thereof,” United States Patent 20060040125. Accessed 10 May 2007

http://www.sulzermetco.com/en/Portaldata/13/Resources/2_Products_Services/Thermal_Spray_Materials_Guide_022006.pdf, Sulzer Metco Thermal Spray Materials Guide, Issued April 2005, p HVOF-13. Accessed 10 May 2007

E. Yun, S. Lee, Correlation of Microstructure with Hardness and Wear Resistance in Cr3C2/Stainless Steel Surface Composites Fabricated by High-Energy Electron Beam Irradiation, Mater. Sci. Eng., A, Vol 405, 2005, p. 163-172

K. Hirota, K. Mitani, M. Yoshinaka, O. Yamaguchi, Simultaneous Synthesis and Consolidation of Chromium Carbides (Cr3C2, Cr7C3 and Cr23C6) by Pulsed Electric-Current Pressure Sintering, Mater. Sci. Eng., A, Vol 399, 2005, p. 154-160

S. Matthews, M. Hyland, B. James, Microhardness Variation in Relation to Carbide Development in Heat Treated Cr3C2-NiCr Thermal Spray Coatings, Acta Mater., Vol 51, 2003, p. 4267-4277

Acknowledgments

This work was partly supported by the Tianjin Natural Scientific Research Foundation (No. 07JCYBJC18200), and by the Research Fund for the Doctoral Program of Higher Education of China (No. 20070056097) and by the National Natural Science Foundation of China (No. 50805104).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2008 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray Crossing Borders, Proceedings of the 2008 International Thermal Spray Conference, Maastricht, The Netherlands, June 2-4, 2008, Basil R. Marple, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and Ghislain Montavon, Ed., ASM International, Materials Park, OH, 2008.

Rights and permissions

About this article

Cite this article

Ye, FX., Wu, SH. & Ohmori, A. Microstructure and Oxidation Behavior of Cr39Ni7C Cermet Coatings Deposited by Diamond Jet Spray Process. J Therm Spray Tech 17, 942–947 (2008). https://doi.org/10.1007/s11666-008-9260-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-008-9260-7