Abstract

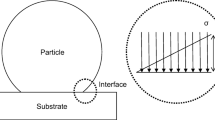

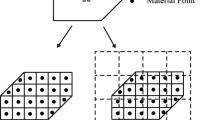

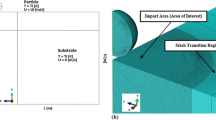

The effect of cold spray temperature and substrate hardness on particle deformation and adhesion has been studied, with particular emphasis on adiabatic shearing leading to melting. Copper particles were cold sprayed onto commercial purity (CP) aluminum and alloy 7050-T7451, with stagnation temperatures 200, 400, and 600 °C. Deposition efficiency, assisted by particle embedding, increased with temperature and was higher on the softer CP substrate. Crater surfaces, adhered particles, and interfaces were characterized by scanning electron microscopy, focused ion beam, and transmission electron microscopy. For comparison, the impact of 15 μm Cu particles was simulated using finite element modeling. A thin layer of material on the substrate-side of the interface was predicted to reach melting point on both substrates at higher impact velocities. Formation of a molten layer was found experimentally. At 600 °C, the effect of substrate heating by the gas jet could not be ignored.

Similar content being viewed by others

References

A. Papyrin, V. Kosarev, S. Klinkov, A. Alhimov, and V. Fomin, Cold Spray Technology, Elsevier, Amsterdam, 2007

R.C. McCune, A.N. Papyrin, J.N. Hall, W.L. Riggs, and P.H. Zajchowski, An Exploration of the Cold Gas-Dynamic Spray Method for Several Materials Systems, Proceedings, 8th National Thermal Spray Conference, C.C. Berndt and S. Sampath, Eds., ASM International, Materials Park, OH, 1995, p 1-5

P.C. King, S.H. Zahiri, M. Jahedi, and J. Friend, Cold Spray Electroding of Piezoelectric Ceramic, Mater. Forum, 2007, 31, p 116-119

P.C. King, S.H. Zahiri, and M.Z. Jahedi, Rare Earth/Metal Composite Formation by Cold Spray, J. Therm. Spray Technol., 2007, 17(2), p 221-227

T. Stoltenhoff, H. Kreye, and H.J. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Therm. Spray Technol., 2002, 11(4), p 542-550

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Design, 2004, 25(8), p 681-688

P.C. King, S.H. Zahiri, and M.H. Jahedi, Focussed Ion Beam Micro-Dissection of Cold Sprayed Particles, Acta Mater., 2008, 56(19), p 5617-5626

S. Guetta, M.H. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, F. Poitiers, Y. Ichikawa, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, Thermal Spray 2008: Crossing Borders, E. Lugscheider, Ed., ASM International, Materials Park, OH, 2008,

P.C. King, S.H. Zahiri, and M. Jahedi, Microstructural Refinement Within a Cold Sprayed Copper Particle, Metall. Mater. Trans. A, 2009, 40(9), p 2115-2123

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3-4), p 211-227

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8(4), p 559-564

A.P. Alkhimov, S.V. Klinkov, and V.F. Kosarev, Temperature Near the Contact Boundary at High-Velocity Collision of a Microparticle and a Surface, Phys. Mesomech., 2000, 3, p 53-57

X.-J. Ning, J.-H. Jang, H.-J. Kim, C.-J. Li, and C. Lee, Cold Spraying of Al-Sn Binary Alloy: Coating Characteristics and Particle Bonding Features, Surf. Coat. Technol., 2008, 202, p 1681-1687

C.-J. Li, W.-Y. Li, and Y.-Y. Wang, Formation of Metastable Phases in Cold-Sprayed Soft Metallic Deposit, Surf. Coat. Technol., 2005, 198(1-3), p 469-473

J. Wu, H. Fang, H. Kim, and C. Lee, High Speed Impact Behaviors of Al Alloy Particle onto Mild Steel Substrate During Kinetic Deposition, Mater. Sci. Eng. A, 2006, 417(1-2), p 114-119

W.-Y. Li, C. Zhang, X. Guo, C.-J. Li, H. Liao, and C. Coddet, Study on Impact Fusion at Particle Interfaces and Its Effect on Coating Microstructure in Cold Spraying, Appl. Surf. Sci., 2007, 254(2), p 517-526

S. Barradas, V. Guipont, R. Molins, M. Jeandin, M. Arrigoni, M. Boustie, C. Bolis, L. Berthe, and M. Ducos, Laser Shock Flier Impact Simulation of Particle-Substrate Interactions in Cold Spray, J. Therm. Spray Technol., 2007, 16(4), p 475-479

S. Guetta, M. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, Y. Ichikawa, K. Sakaguchi, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18(3), p 331–342

A. Wank, B. Wielage, H. Podlesak, and T. Grund, High-resolution microstructural investigations of interfaces between light metal alloy substrates and cold gas-sprayed coatings, J. Therm. Spray Technol., 2006, 15(2), p 280-283

A.V. Bolesta, V.M. Fomin, M.R. Sharafutdinov, and B.P. Tolochko, Investigation of Interface Boundary Occurring During Cold Gas-Dynamic Spraying of Metallic Particles, Nucl. Instrum. Meth. A, 2001, 470(1-2), p 249-252

J.L. Robinson, Fluid Mechanics of Copper: Viscous Energy Dissipation in Impact Welding, J. Appl. Phys., 1977, 48(6), p 2202-2207

V.K. Champagne, D. Helfritch, P. Leyman, S. Grendahl, and B. Klotz, Interface Material Mixing Formed by the Deposition of Copper on Aluminium by Means of the Cold Spray Process, J. Therm. Spray Technol., 2005, 14(3), p 330-334

K. Balani, A. Agarwal, S. Seal, and J. Karthikeyan, Transmission Electron Microscopy of Cold Sprayed 1100 Aluminum Coating, Scripta Mater., 2005, 53(7), p 845-850

Y. Xiong, K. Kang, G. Bae, S. Yoon, and C. Lee, Dynamic Amorphization and Recrystallization of Metals in Kinetic Spray Process, Appl. Phys. Lett., 2008, 92, p 194101

K. Kim, M. Watanabe, K. Mitsuishi, K. Iakoubovskii, and S. Kuroda, Impact Bonding and Rebounding Between Kinetically Sprayed Titanium Particle and Steel Substrate Revealed by High-Resolution Electron Microscopy, J. Phys. D Appl. Phys., 2009, 42(6), p 5

R.C. Dykhuizen and M.F. Smith, Gas Dynamic Principles of Cold Spray, J. Therm. Spray Technol., 1998, 7(2), p 205-212

W.Y. Li and C.J. Li, Optimal Design of a Novel Cold Spray Gun Nozzle at a Limited Space, J. Therm. Spray Technol., 2005, 14(3), p 391-396

B. Jodoin, Cold Spray Nozzle Mach Number Limitation, J. Therm. Spray Technol., 2002, 11(4), p 496-507

S.P. Pardhasaradhi, V. Venkatachalapathy, S.V. Joshi, and S. Govindan, Optical Diagnostics Study of Gas Particle Transport Phenomena in Cold Gas Dynamic Spraying and Comparison with Model Predictions, J. Therm. Spray Technol., 2008, 17(4), p 551-563

J.D. Anderson, Modern Compressible Flow: with Historical Perspective, 3rd ed., McGraw-Hill, New York, 2003

Fluent 6.1 User’s Guide, ANSYS, Inc., Canonsburg, PA

C.B. Henderson, Drag Coefficients of Spheres in Continuum and Rarefied Flows, AIAA J., 1976, 14(6), p 707-708

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process, J. Therm. Spray Technol., 1999, 8(4), p 576-582

L.A. Giannuzzi and F.A. Stevie, A Review of Focused Ion Beam Milling Techniques for TEM Specimen Preparation, Micron, 1999, 30(3), p 197-204

J. Li, T. Malis, and S. Dionne, Recent Advances in FIB-TEM Specimen Preparation Techniques, Mater. Charact., 2006, 57(1), p 64-70

ABAQUSTM 6.7-2 User Manual, Dessault Systemes Simulia Corp., Providence, RI, 2007

G.R. Johnson, and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures, Proceedings of the 7th International Ballistics Symposium, 1983, p 541-547

Matweb, Available from: www.matweb.com

K.A. Dannemann, C.E. Anderson, and G.R. Johnson, Modeling the Ballistic Impact Performance of Two Aluminum Alloys, Modelling the Performance of Engineering Structural Materials II, D.R. Leseur and T.S. Srivatsan, Ed., TMS, 2001, p 63-74

W. Herrmann and J.S. Wilbeck, Review of Hypervelocity Penetration Theories: Hypervelocity Impact Proceedings of the 1986 Symposium, Int. J. Impact Eng., 1987, 5(1-4), p 307-322

L.E. Murr, S.A. Quinones, E. Ferreyra, T.A. Ayala, O.L. Valerio, F. Horz, and R.P. Bernhard, The Low-Velocity-to-Hypervelocity Penetration Transition for Impact Craters in Metal Targets, Mater. Sci. Eng. A, 1998, 256(1-2), p 166-182

E. Irissou, J.G. Legoux, C. Moreau, and A.N. Ryabinin, How Cold is Cold Spray? An Experimental Study of the Heat Transfer to the Substrate in Cold Gas Dynamic Spraying, Thermal Spray 2008: Crossing Borders, E. Lugscheider, Ed., ASM International, Materials Park, OH, 2008

M.S. Anand, S.P. Murarka, and R.P. Agarwala, Diffusion of Copper in Nickel and Aluminum, J. Appl. Phys., 1965, 36(12), p 3860-3862

N. Isono, P. Smith, D. Turnbull, and M. Aziz, Anomalous Diffusion of Fe in Liquid Al Measured by the Pulsed Laser Technique, Metall. Mater. Trans. A, 1996, 27(3), p 725-730

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt, and F. Gartner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47(7), p 1697-1702

J. Legoux, E. Irissou, and C. Moreau, Effect of Substrate Temperature on the Formation Mechanism of Cold-Sprayed Aluminum, Zinc and Tin Coatings, J. Therm. Spray Technol., 2007, 16(5), p 619-626

M. Fukumoto, H. Wada, K. Tanabe, M. Yamada, E. Yamaguchi, A. Niwa, M. Sugimoto, and M. Izawa, Effect of Substrate Temperature on Deposition Behavior of Copper Particles on Substrate Surfaces in the Cold Spray Process, J. Therm. Spray Technol., 2007, 16(5), p 643-650

K. Kang, S. Yoon, Y. Ji, and C. Lee, Oxidation Dependency of Critical Velocity for Aluminum Feedstock Deposition in Kinetic Spraying Process, Mater. Sci. Eng. A, 2008, 486(1-2), p 300-307

G.R. Cowan and A.H. Holtzman, Flow Configurations in Colliding Plates: Explosive Bonding, J. Appl. Phys., 1963, 34(4), p 928-939

B. Crossland and J.D. Williams, Explosive Welding, Met. Mater., 1970, 4, p 79-100

J. Vlcek, L. Gimeno, H. Huber, and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold-Spray Process, J. Therm. Spray Technol., 2005, 14(1), p 125-133

D. Zhang, P.H. Shipway, and D.G. McCartney, Cold Gas Dynamic Spraying of Aluminium: The Role of Substrate Characteristics in Deposit Formation, J. Therm. Spray Technol., 2005, 14(1), p 109-116

Acknowledgments

This work was supported by a Korean Science and Engineering Foundation (KOSEF) grant funded by the Korean government (MOST) (No. 2006-02289). The authors would like to thank Jens Oqueka, from Helmut Schmidt University, University of the Federal Armed Forces, Hamburg, Germany, for his assistance in implementing some of the particle acceleration model into code.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

King, P.C., Bae, G., Zahiri, S.H. et al. An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates. J Therm Spray Tech 19, 620–634 (2010). https://doi.org/10.1007/s11666-009-9454-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9454-7