Abstract

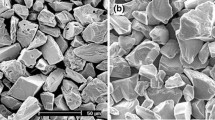

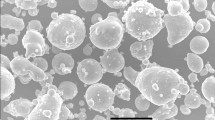

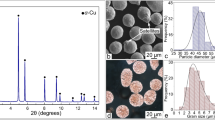

Profile nanoindentation and nanoindentation mapping were used to investigate the mechanical properties of commercially pure cold spray Ti splats and coatings deposited at increasing deposition velocities. Three regions in the cold spray Ti splats have been indentified: the impact region, the jetting region, and the upper splat region. The mechanical properties measured in these regions were tied to the cold spray deposition process with help of optical and scanning electron microscopes. The jetting region was observed to contribute to a metallurgical bonding of cold spray splats to cold spray splats and was measured to have low hardness in comparison to the splat impact site and similar to the hardness in the upper splat region. No increase in the profile coatings hardness with increase in the particle in-flight velocity and coating thickness was found. A correlation between the mechanical properties and the presently known deposition temperature, stress and dislocation density models was made.

Similar content being viewed by others

References

E. Irissou, J.G. Legoux, A. Ryabinin, B. Jodoin, and C. Moreau, Review on Cold Spray Process and Technology: Part I, Intellectual Property, J. Therm. Spray Technol., 2008, 17(4), p 495-516

A. Papyrin, V. Kosarev, K. V. Klinkov, A. Alkhimov, and V. M. Fomin, Cold Spray Technology, Elsevier, Oxford, 2006, p 74, 153-169, 259

V.K. Champagne, The Cold Spray Materials Deposition Process: Fundamentals and Applications, Woodhead Publishing Limited, Cambridge, 2007, p 362

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

C.-J. Li, W.-Y. Li, and H. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 15(2), p 212-222

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

T. Schmidt, F. Gaertner, and H. Kreye, New Developments in Cold Spray Based on Higher Gas and Particle Temperatures, J. Therm. Spray Technol., 2006, 15(4), p 488-494

C. Borchers, F. Gartner, T. Stoltenhoff, and H. Kreye, Microstructural Bonding Features of Cold Sprayed Face Centered Cubic Metals, J. Appl. Phys., 2004, 96(8), p 4288-4292

T. Kairet, M. Degrez, F. Campana, and J.P. Janssen, Influence of the Powder Size Distribution on the Microstructure of Cold-Sprayed Copper Coatings Studied by X-ray Diffraction, J. Therm. Spray Technol., 2007, 16(5), p 610-618

A. Rezaeian, E. Irissou, R.R. Chromik, S. Yue, Characterization of Cold-Sprayed Ni, Ti, Cu Coating Properties for their Optimization, Thermal Spray: Crossing Borders, Jun 2-4, 2008 (Maastricht, The Netherlands), ASM International, p 854-859

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, D.W. Gorkiewicz, R.P. Tison, D.R. Marantz, K.A. Kowalsky, W.L. Riggs, P.H. Zajchowski, B. Pilsner, R.C. McCune, and K.J. Barnett, Kinetic Spray Coatings, Surf. Coat. Technol., 1999, 111(1), p 62-71

T. Stoltenhoff, C. Borchers, F. Gärtner, and H. Kreye, Microstructures and Key Properties of Cold-Sprayed and Thermally Sprayed Copper Coatings, Surf. Coat. Technol., 2006, 200(16-17), p 4947-4960

S. Zahiri, D. Fraser, and M. Jahedi, Recrystallization of Cold Spray-Fabricated CP Titanium Structures, J. Therm. Spray Technol., 2009, 18(1), p 16-22

C.-J. Li and W.-Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167(2-3), p 278-283

W.Y. Li, C. Zhang, X. Guo, J. Xu, C.J. Li, H. Liao, C. Coddet, and K.A. Khor, Ti and Ti-6Al-4V Coatings by Cold Spraying and Microstructure Modification by Heat Treatment, Adv. Eng. Mater., 2007, 9(5), p 418-423

R.S. Lima, A. Kucuk, C.C. Berndt, J. Karthikeyan, C.M. Kay, and J. Lindemann, Deposition Efficiency, Mechanical Properties and Coating Roughness in Cold-Sprayed Titanium, J. Mater. Sci. Lett., 2002, 21(21), p 1687-1689

T. Marrocco, D. McCartney, P. Shipway, and A. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

J. Vlcek, H. Huber, H. F. Voggenreiter, and E. Lugscheider, Melting Upon Particle Impact in the Cold Spray Process, International Congress on Advanced Materials, Their Process and Applications, September 30-October 2, 2002 (Munich, Germany), Deutsche Gesellschaff Fur Materialkunde (DSM)

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H.J. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666

K. Kim, M. Watanabe, K. Mitsuishi, K. Iakoubovskii, and S. Kuroda, Impact Bonding and Rebounding Between Kinetically Sprayed Titanium Particle and Steel Substrate Revealed by High-Resolution Electron Microscopy, J. Appl. Phys. D, 2009, 42(6), p 65304

W. Wong, A. Rezaeian, E. Irissou, J.G. Legoux, and S. Yue, Cold Spray Characteristics of Commercially Pure Ti and Ti-6Al-4V, Adv. Mater. Res., 2010, 89-91, p 639-644

K.-H. Kim, M. Watanabe, J. Kawakita, and S. Kuroda, Grain Refinement in a Single Titanium Powder Particle Impacted at High Velocity, Scripta Mater., 2008, 59(7), p 768-771

K.-H. Kim, M. Watanabe, J. Kawakita, and S. Kuroda, Effects of Temperature of In-flight Particles on Bonding and Microstructure in Warm-Sprayed Titanium Deposits, J. Therm. Spray Technol., 2009, 18(3), p 392-400

R. Kapoor and S. Nemat-Nasser, Determination of Temperature Rise During High Strain Rate Deformation, Mech. Mater., 1998, 27(1), p 1-12

A. C. Fisher-Cripps, Nanoindentation, 2nd ed., Springer, New York, 2002, p 1-20.

W.C. Oliver and G.M. Pharr, Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology, Mater. Res. Soc., 2004, 19(1), p 3-20

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

J.J. Vlassak and W.D. Nix, Measuring the Elastic Properties of Anisotropic Materials by Means of Indentation Experiments, J. Mech. Phys. Solids, 1994, 42(8), p 1223-1245

J.J. Vlassak, M. Ciavarella, J.R. Barber, and X. Wang, The Indentation Modulus of Elastically Anisotropic Materials for Indenters of Arbitrary Shape, J. Mech. Phys. Solids, 2003, 51(9), p 1701-1721

Acknowledgments

Financial support from the Canadian Foundation for Innovation is gratefully acknowledged; the cold spray equipment was provided by CFI project No. 8246 while the nanoindentation equipment was provided by CFI, Leader’s Opportunity Fund, project No. 13029. Operational funding for this project was provided by the Natural Sciences and Engineering Research Council (NSERC) Strategic Grants Program. The authors acknowledge the technical assistance of Ahmad Rezaeian, Bernard Harvey and Frederic Belval.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goldbaum, D., Chromik, R.R., Yue, S. et al. Mechanical Property Mapping of Cold Sprayed Ti Splats and Coatings. J Therm Spray Tech 20, 486–496 (2011). https://doi.org/10.1007/s11666-010-9546-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9546-4