Abstract

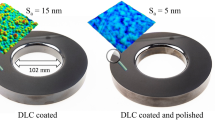

Two approaches to produce wear-resistant effective surfaces for deep drawing tools by thermal arc wire spraying of hard materials are presented. Arc wire spraying is a very economic coating technique due to a high deposition rate. The coated surface is very rough compared to that of conventional sheet metal forming tools. In the first approach, the coated surface is smoothed in a subsequent CNC-based incremental roller burnishing process. In this process, the surface asperities on the surface are flattened, and the roughness is significantly reduced. In the second approach, the hard material coatings are not sprayed directly on the tool but on a negative mould. Afterward, the rough “as-sprayed” side of the coating is backfilled with a polymer. The bonded hard metal shell is removed from the negative mould and acts as the surface of the hybrid sheet metal forming tool. Sheet metal forming experiments using tools based on these two approaches demonstrate that they are suitable to form high-strength steels. Owing to a conventional body of steel or cast iron, the first approach is suitable for large batch sizes. The application of the second approach lies within the range of small up to medium batch size productions.

Similar content being viewed by others

References

M. Kleiner, M. Geiger, and A. Klaus, Manufacturing of Lightweight Components by Metal Forming, CIRP Ann. Manuf. Technol., 2003, 52(2), p 521-542

S. Wagner, “3D-Beschreibung der Oberflächenstrukturen von Feinblechen,” Dissertation, TU Stuttgart, 1996

E. Dannenmann, Ermittlung von Reibungszahlen für Verfahren der Blechumformung, Industrial and Automotive Lubrication, 11th International Colloquium, W.J. Bartz, Hg., January 13-15, 1998 (Ostfildern, TAE), 1998, ISBN 3-924813-39-6 (Beitrag in Sammelwerk), p 2373-2385

M.P.F. Sutcliffe, Surface Asperity Deformation in Metal Forming Processes, Int. J. Mech. Sci., 1988, 30(11), p 847-868

D. Schmoeckel, H. Frontzek, and E. von Finckenstein, Reduction of Wear on Sheet Metal Forming Tools, CIRP Ann. Manuf. Technol., 1986, 35, p 195-198

E. Dannenmann, R. Geiger, and T. Gräbner, Tribologische Grundlagen, Oberflächenwandlung, Umformtechnik Band 1: Grundlagen, K. Lange, Hg., Springer-Verlag, 1984, p 239-306

N. Bay and T. Wanheim, Real Area of Contact and Friction Stress at High Pressures Sliding Contact, Wear, 1976, 38, p 201-209

M. Pfestorf, J. Staeves, and S. Wagner, Definition von 3D-Oberflächenkenngrößen, Stahl und Eisen, 1997, 117(7), p 89-94

J. Staeves, “Beurteilung der Topografie von Blechen im Hinblick auf die Reibung bei der Umformung,” Dissertation, TU Darmstadt, 1998

Th. Neudecker, U. Popp, T. Schraml, U. Engel, and M. Geiger, Towards Optimized Lubrication by Micro Texturing of Tool Surfaces, Advanced Technology of Plasticity, Vol 1, Proceedings of the 6th ICTP—International Conference on Technology of Plasticity, Nürnberg, Germany, 1999, p 619-626

V. Boljanovic and J. R. Paquin, Die Design Fundamentals, 3rd ed., Industrial Pr Inc, 2005

S.L. Semiatin, Forming and Forging, ASM Handbook, 3rd ed., ASM International, 1993

P. Panjan, I. Boncina, J. Bevk, and M. Cekada, PVD Hard Coatings Applied for the Wear Protection of Drawing Dies, Surf. Coat. Technol., 2005, 200(1-4), p 133-163

K. Eversberg, Produkt-Kostenreduzierung in der Blechbearbeitung mittels Hartstoffbeschichtung, Proceedings of the International Conference VDI Blechbearbeitung, Vol 1277, October 22-23, 1996 (Hannover, Germany), 1996, p 291-310

M. Murakawa, M. Jin, and M. Hayashi, Study on Semidry/Dry Wire Drawing Using DLC Coated Dies, Surf. Coat. Technol., 2004, 177-178, p 631-637

J.R. Davis, Ed., Handbook of Thermal Spray Technology, 1st ed., ASM International, 2004

W. Tillmann, E. Vogli, I. Baumann, and J. Nebel, Verschleißminderung durch Wolframcarbid und Chromcarbid basierte Spritzschichten, SFB 708-2. öffentliches Kolloquium, W. Tillmann, Hg., Praxiswissen (3D-Surface Engineering für Werkzeugsysteme der Blechformteilefertigung, 2), Dortmund, 2008, p 97-109

S.J. Bull, R.I. Davidson, E.H. Fisher, A.R. McCabe, and A.M. Jones, A Simulation Test for the Selection of Coatings and Surface Treatments for Plastics Injection Moulding Machines, Surf. Coat. Technol., 2000, 130(2-3), p 257-265

D. Biermann, T. Mohn, H. Blum, and H. Kleemann, Grinding of Arc-Sprayed Tungsten Carbide Coatings on Machining Centers—Process Configuration and Simulation, Key Eng. Mater., 2010, 438, p 115-122

V. Franzen, A. Brosius, and A.E. Tekkaya, Einflussfaktoren auf das Glattwalzen thermisch gespritzter Schichten, SFB 708-2. öffentliches Kolloquium, W. Tillmann, Hg., Praxiswissen (3D-Surface Engineering für Werkzeugsysteme der Blechformteilefertigung, 2), Dortmund, 2008, p 113-120

W. Tillmann, E. Vogli, B. Krebs, A.E. Tekkaya, A. Brosius, and V. Franzen, Densification of Atmospheric Plasma Sprayed Wear Resistant Coatings, Proceedings of the International Thermal Spray Conference—ITSC 2009, May 4-7, 2009 (Las Vegas, NV, USA), 2009, p 1045-1051

R. Näf, Die Alternative zum Schleifen. Glattwalzen auf Bearbeitungszentrum und Drehmaschine, Schweizer Maschinenmarkt, 1999, 22(31), p 28-29

K. Röttger, Festwalzen und Glattwalzen als wirtschaftliche Feinbearbeitungsverfahren, Konferenz-Einzelbericht: Moderne Schleiftechnologie und Feinstbearbeitung, Vol 5, FH Furtwangen, Villingen-Schwenningen, 2004, p 1-13

E. Broszeit and H. Steindorf, Mechanische Oberflächenbehandlung—Festwalzen, Kugelstrahlen, Sonderverfahren, DGM Informationsgesellschaft Verlag, Frankfurt, 1989

J. Witulski, M. Trompeter, A. Brosius, and A.E. Tekkaya, Development of a Hybrid Deep Drawing Tool Using Thermally Coated Surfaces, Proceedings of the IDDRG International Conference, June 16-18, 2008 (Olofström, Sweden), 2008, p 627-638

J. Witulski, M. Trompeter, and A.E. Tekkaya, Fiber-Reinforced Polymers for Rapid Tooling of Deep Drawing Tools of a High Wear Resistance, Proceedings of the IDDRG International Conference, June 2-4 2009 (Golden, CO, USA), 2009, p 761-772

Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method, E837, ASTM International Standard, 2001

J. Nebel, J. Vogli, and W. Tillmann, Arc Spraying of WC-FeCSiMn Cored Wires. Part 1: Bending, Compression and Tension Behavior, Proceedings of the International Thermal Spray Conference & Exposition 2010, Thermal Spray: Global Solutions for Future Application ITSC 2010, May 3-5, 2010 (Singapore), 2010, p 592-600

C.A. Coulomb, Memoires de Mathematique et de Physique de l’Academie Royale des Sciences, 1785, p 161

G. Oehler and F. Kaiser, Schnitt-, Stanz- und Ziehwerkzeuge, 8th ed., Springer, Heidelberg, 2001

K. Galanulis, C. Reich, J. Thesing, and D. Winter, Optical Digitizing by ATOS for Press Parts and Tools, GOM Gesellschaft für optische Messtechnik mbH, Braunschweig, 2010, http://www.gom.com

V. Franzen, A. Brosius, and A.E. Tekkaya, Optimierung der Funktionseigenschaften thermisch gespritzter Oberflächenbe-schichtungen durch einen Glattwalzprozess, SFB 708-3. öffentliches Kolloquium, W. Tillmann, Hg., Praxiswissen (3D-Surface Engineering für Werkzeugsysteme der Blechformteilefertigung, 3), Dortmund, 2009, p 31-40

B. Denkena, J. Dege, and Ch. Müller, Beeinflussung der Randzoneneigenschaften des Werkstoffs 42CrMo4 durch einen geregelten Festwalzprozess, HTM, 2006, 61(1), p 43-46

Deutscher Verband für Materialforschung und -prüfung e.V.—DVM: Festwalzen und Glattwalzen zur Festigkeitssteigerung von Bauteilen, Vorträge der 8.Sitzung des Arbeitskreises Betriebsfestigkeit, 1982

Acknowledgments

The Collaborative Research Center Program titled “3D-Surface Engineering of Tools for Sheet Metal Forming—Manufacturing, Modelling, Machining (SFB708)” is kindly supported by the German Research Foundation (DFG)—the central public funding organization for academic research in Germany.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Franzen, V., Witulski, J., Brosius, A. et al. Thermally Sprayed Coatings as Effective Tool Surfaces in Sheet Metal Forming Applications. J Therm Spray Tech 20, 939–947 (2011). https://doi.org/10.1007/s11666-011-9627-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-011-9627-z