Abstract

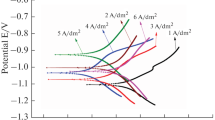

In this study, the corrosion and wear performance of Ni-Ti composite coatings with distinct parameters were investigated. The coatings were prepared by arc spraying with Ti and Ni wires fed synchronously. Structural, surface morphological, and compositional analyses of the Ni-Ti composite coatings were performed using microhardness, SEM/EDS, XRD, and DTA analysis. Electrochemical AC impedance and potentiodynamic polarization tests were carried out to examine the anticorrosion performance of the coating. Ball-on-disc dry wear tests based on the ASTM G99 standard were performed at room temperature to evaluate the antiwear properties. The DTA and XRD analysis results indicated that some intermetallic compounds such as TiNi3 and Ni-Ti alloy were present within the Ni-Ti coating. The wear resistance of the Ni-Ti composite coating is superior to that of the Ni-sprayed coating but slightly inferior to that of the Ti-sprayed coating. The corrosion resistance of the arc-sprayed Ni-Ti coating is superior to that of Ti but inferior to that of Ni. The corrosion and wear performance of the composite coating are greatly influenced by the coating microstructure and thickness.

Similar content being viewed by others

References

E.R. Sampson, Thermal Spray Coatings for Corrosion Protection: An Overview, Mater. Perform., 1997, 38(12), p 27-30

B. Fitzsimons, Thermal Spray Metal Coatings for Corrosion Protection, Corros. Manag., Dec. 1995/Jan. 1996, p 12-17

L.E. Weiss, F.B. Prinz, and E.L. Gursoz, Rapid Tool Manufacturing, U.S. Patent 5,189,781, 1993

L.E. Weiss, D.G. Thuel, L. Schultz, and F.B. Prinz, Arc Sprayed Steel-Faced Tooling, J. Therm. Spray Technol., 1994, 3(3), p 275-281

L.E. Weiss and F.B. Prinz, A Thermal Spray Approach to Rapid Prototyping—An Extended Abstract, J. Therm. Spray Technol., 1994, 3(3), p 297-298

A.P. Jardine, Y. Horan, and H. Herman, Cavitation Erosion Resistance of Thick Film Thermally Sprayed Ni-Ti High Temperature Ordered Intermetallic Alloys IV, Proceedings of the 4th MRS Symposium, Boston, MA, 27-30 Nov. 1990, p 815-820

L.M. Qian, Z.R. Zhou, and Q.P. Sun, The Role of Phase Transition in the Fretting Behavior of Ni-Ti Shape Memory Alloy, Wear, 2005, 259, p 309-318

D.Y. Li, A New Type of Wear-Resistant Material: Pseudo-Elastic TiNi Alloy, Wear, 1998, 221, p 116-123

D.Y. Li and R. Liu, The Mechanism Responsible for High Wear Resistance of Pseudo-Elastic TiNi Alloy—A Novel Tribo-Material, Wear, 1999, 225-229, p 777-783

H.C. Lin, H.M. Liao, J.L. He, K.M. Lin, and K.C. Chen, Wear Characteristics of Ion-Nitrided Ti50Ni50 Shape Memory Alloys, Surf. Coat. Technol., 1997, 92, p 178-189

H. Hiraga, T. Inoue, H. Shimura, and A. Matsunawa, Cavitation Erosion Mechanism of NiTi Coatings Made by Laser Plasma Hybrid Spraying, Wear, 1999, 231, p 272-278

T. Watanabe, T. Sato, and A. Nezu, Electrode Phenomena Investigation of Wire Arc Spraying for Preparation of Ti-Al Intermetallic Compounds, Thin Solid Films, 2002, 407, p 98-103

N. Sakoda, M. Hida, Y. Takemoto, A. Sakakibara, and T. Tajiri, Influence of Atomization Gas on Coating Properties Under Ti Arc Spraying, Mater. Sci. Eng. A, 2003, 342, p 264-269

B.S. Xu, Z.X. Zhu, S.N. Ma, W. Zhang, and W.M. Liu, Sliding Wear Behavior of Fe-Al and Fe-Al/WC Coatings Prepared by High Velocity Arc Spraying, Wear, 2004, 257, p 1089-1095

J.A. Hearley, J.A. Little, and A.J. Sturgeon, The Erosion Behaviour of NiAl Intermetallic Coatings Produced by High Velocity Oxy-Fuel Thermal Spraying, Wear, 1999, 233-235, p 328-333

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, C.H., Jeng, M.C., Su, C.Y. et al. A Study of Wear and Corrosion Resistance of Arc-Sprayed Ni-Ti Composite Coatings. J Therm Spray Tech 20, 1278–1285 (2011). https://doi.org/10.1007/s11666-011-9679-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-011-9679-0