Abstract

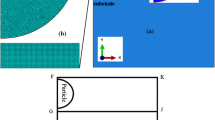

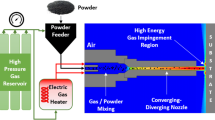

In cold spraying (CS), critical velocity of particles is one of the most important parameters. The impacting particle and substrate inevitably undergo a strong thermomechanical coupling process at the contacting interface and serious plastic deformation in a very short time. In this paper, a coupled thermomechanical Eulerian (CTM-Eulerian) model was, for the first time, developed for CS particles to investigate plastic deformation and heat conduction within the bulk, and to predict the critical velocity. Results show that heat conduction has a significant effect on the temperature distribution within the particle which will influence the atom diffusion at the impacting interface, while a little influence on plastic deformation. Moreover, based on the deformed particle shapes and plastic strain analysis, a calculated critical velocity of about 300 m/s for copper is obtained. Finally, this CTM-Eulerian model is extended to other commonly sprayed materials and the predicted critical velocities of Fe, Ni, SS304, Al, In718, and TC4 are about 350, 380, 395, 410, 490, and 500 m/s, respectively.

Similar content being viewed by others

References

H. Assadi, F. Gartner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 15(51), p 4379-4394

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 3(54), p 729-742

J.H. Lee, S.M. Shin, H.J. Kim, and C.H. Lee, Effect of Gas Temperature on Critical Velocity and Deposition Characteristics in Kinetic Spraying, Appl. Surf. Sci., 2007, 253(7), p 3512-3520

X.J. Ning, J.H. Jang, and H.J. Kim, The Effects of Powder Properties on In-Flight Particle Velocity and Deposition Process during Low Pressure Cold Spray Process, Appl. Surf. Sci., 2007, 253(18), p 7449-7455

H.J. Kim, C.H. Lee, and S.Y. Hwang, Superhard Nano WC-12%Co Coating by Cold Spray Deposition, Mater. Sci. Eng. A, 2005, 391(1-2), p 243-248

C.J. Li, W.Y. Li, and H.L. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 2(15), p 212-222

K. Kang, S.H. Yoon, Y.W. Ji, and C.H. Lee, Oxidation Dependency of Critical Velocity for Aluminum Feedstock Deposition in Kinetic Spraying Process, Mater. Sci. Eng. A, 2008, 486(1-2), p 300-307

W.Y. Li, H.L. Liao, C.J. Li, G. Li, C. Coddet, and X.F. Wang, On High Velocity Impact of Micro-Sized Metallic Particles in Cold Spraying, Appl. Surf. Sci., 2006, 5(253), p 2852-2862

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 8(25), p 681-688

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 17(56), p 4858-4868

W.Y. Li, H.L. Liao, C.J. Li, H.S. Bang, and C. Coddet, Numerical Simulation of Deformation Behavior of Al Particles Impacting on Al Substrate and Effect of Surface Oxide Films on Interfacial Bonding in Cold Spraying, Appl. Surf. Sci., 2007, 11(253), p 5084-5509

W.Y. Li and W. Gao, Some Aspects on 3D Numerical Modeling of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, Appl. Surf. Sci., 2009, 18(255), p 7878-7892

W.Y. Li, S. Yin, and X.F. Wang, Numerical Investigations of the Effect of Oblique Impact on Particle Deformation in Cold Spraying by the SPH Method, Appl. Surf. Sci., 2010, 12(256), p 3725-3734

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Therm. Spray Technol., 1999, 8(4), p 559-564

S. Yin, X.F. Wang, B.P. Xu, and W.Y. Li, Examination on the Calculation Method for Modeling the Multi-Particle Impact Process in Cold Spraying, J. Therm. Spray Technol., 2010, 5(19), p 1032-1041

M. Yu, W.Y. Li, F.F. Wang, and H.L. Liao, Finite Element Simulation of Impacting Behavior of Particles in Cold Spraying by Eulerian Approach, J. Therm. Spray Technol., 2012, 21(3-4), p 745-752

S.R. Beissel, C.A. Gerlach, and G.R. Johnson, Hypervelocity Impact Computation with Finite Elements and Meshfree Particles, Int. J. Impact. Eng., 2006, 33(1-12), p 89-90

A.R. Khoei, A.R. Azami, M. Anahid, and R.W. Lewis, A Three-Invariant Hardening Plasticity for Numerical Simulation of Powder Forming Processes Via the Arbitrary Lagrangian-Eulerian FE Model, Int. J. Numer. Methods Eng., 2006, 5(66), p 843-877

Abaqus Analysis User’s Manual, ABAQUS 6.12 HTML Documentation, Dassault Systèmes, 2012

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt, and F. Gartner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47(7), p 1697-1702

T.S. Price, P.H. Shipway, D.G. McCartney, E. Calla, and D. Zhang, A Method for Characterizing the Degree of Inter-particle Bond Formation in Cold Sprayed Coatings, J. Therm. Spray Technol., 2007, 16(4), p 566-570

H.T. Wang, C.J. Li, G.J. Yang, and C.X. Li, Cold Spraying of Fe/Al Powder Mixture: Coating Characteristics and Influence of Heat Treatment on the Phase Structure, Appl. Surf. Sci., 2008, 255(5), p 2538-2544

H.Y. Lee, S.H. Jung, S.Y. Lee, and K.H. Ko, Alloying of Cold-Sprayed Al-Ni Composite Coatings by Post-Annealing, Appl. Surf. Sci., 2007, 253(7), p 3496-3502

M.R. Sørensen, Y. Mishin, and A.F. Voter, Diffusion Mechanisms in Cu Grain Boundaries, Phys. Rev. B, 2000, 62(6), p 3658-3673

J. Vlcek, L. Gimeno, H. Huber, and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold Spray Process, J. Therm. Spray Technol., 2005, 14(1), p 125-133

S.H. Zahiri, D. Fraser, S. Gulizia, and M. Jahedi, Effect of Processing Conditions on Porosity Formation in Cold Gas Dynamic Spraying of Copper, J. Therm. Spray Technol., 2005, 3(15), p 422-430

Acknowledgments

The authors would like to thank for financial support from the Graduate Starting Seed Fund of Northwestern Polytechnical University (2013019), the Fok Ying-Tong Education Foundation for Young Teachers in the Higher Education Institutions of China (131052), and the 111 Project (B08040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F.F., Li, W.Y., Yu, M. et al. Prediction of Critical Velocity During Cold Spraying Based on a Coupled Thermomechanical Eulerian Model. J Therm Spray Tech 23, 60–67 (2014). https://doi.org/10.1007/s11666-013-0009-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-0009-6