Abstract

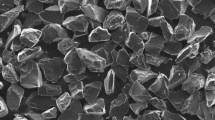

Because of their excellent properties aluminum and its alloys cover a wide range of applications especially in the lightweight construction sector. In order to reach a higher strength and wear resistance metal matrix composites (MMCs) are used. Typically Al MMCs are manufactured by casting or extrusion processes. The disadvantage of these production routes is a cost-intensive and time-consuming finishing in terms of grinding and milling. The technique of thermal spraying provides the possibility to coat aluminum parts with MMCs close to their final shape. In addition to the shape accuracy the ductility and toughness of the coated parts are generally higher compared to extruded or casted parts. This study describes the development of detonation-sprayed boron carbide reinforced aluminum coatings on aluminum (EN AW 5754) substrates. The optimization of the coatings was focused on a homogeneous coating structure, a low coating porosity, a high deposition efficiency, a high number of embedded carbides, and a small percentage of oxides. In continuous tensile tests the influence of the MMC coating on the tensile strength was determined. Furthermore, the tensile strength was investigated in a discontinuous tensile test step by step. The different stages of deformation were analyzed by using micro computed tomography. This method enables the observation of tensile specimens in 3D, and consequently the site and moment of crack formation.

Similar content being viewed by others

References

W. Piersig, Aluminium - ein Metall mit kurzer Geschichte, aber mit großer Zukunft, GRIN Verlag GmbH, Munich, 2010

J. Wiedemann, Leichtbau, Springer Verlag, Berlin, 1996

H. Braess, Handbuch Kraftfahrzeugtechnik, Vieweg Verlag, Wiesbaden, 2007

J. Nebel, “Detonationsspritzen von Diamant-Bronze-Verbundschichten für die Gesteinsbearbeitung,” Ph.D. Thesis, Lehrstuhl für Werkstofftechnologie, TU Dortmund, 2012

F. Bach, K. Möhwald, and T. Wenz, Moderne Beschichtungsverfahren, Wiley, Weinheim, 2005

G. Barbezat, Advanced Thermal Spray Technology and Coating for Lightweight Engine Blocks for the Automotive Industry, Surf. Coat. Technol., 2005, 200, p 1990-1993

L. Josefiak, “Beitrag zur Entwicklung thermisch gespritzter Verschleißschutzschichten für Leichtmetalloberflächen,” Ph.D. Thesis, TU Dortmund, 2002

P. Krug and G. Sinha, Sprühkompaktieren - ein alternatives Herstellverfahren für MMC-Aluminiumlegierungen, Chapter 11, Wiley, New York, 2003, p 296-314

A. Schneider, “Sprühkompaktieren mit Injektion von Feststoffpartikeln,” Ph.D. Thesis, Universität Bremen, 2004

W. Tillmann, E. Vogli, K. Weidemann, and K. Fleck, Reinforced Lightweight Composite Materials, Conference Proceedings Thermal Spray (ITSC), Basel Schweiz, p 1-4

W. Tillmann, E. Vogli, and R. Rechlin, Tribological Behavior of D-Gun and Atmospheric Plasma Spray Coatings on Light Weight Materials, Conference Proceedings Thermal Spray (ITSC), Osaka, p 1-5

W. Tillmann, E. Vogli, and J. Nebel, Detonationsflammspritzen hartstoffhaltiger Funktionsschichten, Materialwiss. Werkstofftech., 2007, 38, p 481-488

E. Sansoucy, P. Marcoux, L. Ajdelsztajn, and B. Jodoin, Properties of SiC-reinforced Aluminum Alloy Coatings Produced by the Cold Gas Dynamic Spraying Process, Surf. Coat. Technol., 2008, 202, p 3988-3996

M. Pasandideh-Fard, “Droplet Impact and Solidification in a Thermal Spray Process,” Master’s Thesis, Department of Mechanical and Industrial Engineering, University of Toronto, 1998

P. Ctibor, R. Lechnerova, and V. Benes, Quantitative Analysis of Pores of Two Types in a Plasma-Sprayed Coating, Mater. Charact., 2006, 56, p 297-304

V. Guipont, G. Rolland, M. Jeandin, C. Peyrega, D. Jeulin, and W. Ludwig, Microstructures of Cold-Sprayed Coatings Investigated by X-ray Microtomography, Therm. Spray Bull., 2010, 2, p 140-147

A. Kulkarni, S. Sampath, A. Goland, H. Herman, and B. Dowd, Computed Microtomography Studies to Characterize Microstructure Property Correlations in Thermal Sprayed Alumina Deposits, Scr. Mater., 2000, 43, p 471-476

F. Beckmann, J. Herzen, A. Haibel, B. Müller, and A. Schreyer, High density resolution in synchrotron-radiation-based attenuation-contrast microtomography, Proceedings of SPIE: Developments in X-Ray Tomography VI, Vol 7078, p 70781D

J. Ilavsky, Characterization of Complex Thermal Barrier Deposits Pore Microstructures by a Combination of Imaging, Scattering, and Intrusion Techniques, J. Therm. Spray Technol., 2010, 19, p 178-189

L. Feldkamp, L. Davis, and J. Kress, Practical Cone Beam Algorithm, J. Opt. Soc. Am. A, 1984, 1, p 612-619

W. Tillmann and P. Hollingsworth, Detonationsspritzen von Borkarbidverstärkten Aluminiumschichtsystemen, Proceedings of 15. Werkstofftechnisches Kolloquium, Chemnitz, 2012

T. Gavrilenko, Y. Nikolaev, V. Ulianitsky, M. Kim, and J. Hong, Computational Code for Detonation Spraying Process, Conference Proceedings Thermal Spray (ITSC), Nizza, Frankreich, 2008, p 1475-1483.

H.-A. Crostack, J. Nellesen, G. Fischer, U. Weber, S. Schmauder, and F. Beckmann, 3D analysis of MMC microstructure and deformation by micro CT and FE simulations, Proceedings of SPIE: Developments in X-Ray Tomography VI, Vol 7078, 2008, p 70781I-1-12

G. Fischer, J. Nellesen, N. Anar, K. Ehrig, H. Riesemeier, and W. Tillmann, 3D Analysis of Micro-Deformation in VHCF-Loaded Nodular cast Iron by Micro CT, Mater. Sci. Eng. A, 2013, 577, p 202-209

Acknowledgments

The work presented here is financially supported by the German Research Foundation (DFG) in the scope of the research projects FI 686/6-1 and TI 343/24-1 which is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2013 International Thermal Spray Conference, held May 13-15, 2013, in Busan, South Korea, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Tillmann, W., Hollingsworth, P.S., Fischer, G. et al. Development and Characterization of B4C Reinforced Detonation-Sprayed Al Coatings. J Therm Spray Tech 23, 289–295 (2014). https://doi.org/10.1007/s11666-013-0036-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-0036-3