Abstract

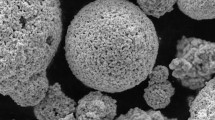

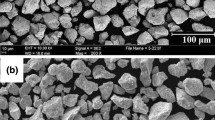

In the present study, WC-12Co coatings were deposited by detonation-spraying technique using conventional and nanostructured WC-12Co feedstock at four different oxy/fuel ratios (OF ratio). The coatings exhibited the presence of phases like W2C and W due to the decarburization of the WC phase, and the proportions of these phases were higher in the nano WC-12Co coatings compared with conventional WC-12Co coatings. Coating hardness and fracture toughness were measured. The tribological performance of coatings was examined under dry sand rubber wheel abrasion wear, and solid particle erosion wear conditions. The mechanical and wear properties of coatings were influenced by degree of decarburization and more so in the case of nanostructured WC-Co coatings. The results indicate that the extent of decarburization has a substantial influence on the elastic modulus of the coating which in turn is related to the extent of intersplat cracking of the coating.

Similar content being viewed by others

References

V. Ramnath and N. Jayaraman, Characterization and Wear Performance of Plasma Sprayed WC-Co Coatings, Mat. Sci. Tech., 1989, 5, p 382-389

M.E. Vinayo, F. Kassabji, J. Guyonnet, and P. Fauchais, Plasma Sprayed WC-Co Coatings: Influence of Spray Conditions (Atmospheric and Low Pressure Plasma Spraying) on the Crystal Structure, Porosity, and Hardness, J. Vac. Sci. Technol. A, 1985, 3, p 2483-2489

D. Tu, S. Chang, C. Chao, and C. Lin, Tungsten Carbide Phase Transformation during the Plasma Spray Process, J. Vac. Sci. Technol. A, 1985, 3, p 2479-2482

Y.C. Zhu, K. Yukimura, C. Ding, and P. Zhang, Tribological Properties of Nanostrucutred and Conventional WC-Co Coatings Deposited by Plasma Spraying, Thin Solid Films, 2001, 388, p 277-282

P. Chivavibul, M. Watanabe, S. Kuroda, and K. Shinoda, Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-sprayed WC-Co Coatings, Surf. Coat. Technol., 2007, 202, p 509-521

Y. Qiao, T.E. Fischer, and A. Dent, The Effects of Fuel Chemistry and Feedstock Powder Structure on the Mechanical and Tribological Properties of HVOF Thermal Sprayed WC-Co Coatings with Very Fine Structures, Surf. Coat. Technol., 2003, 172, p 24-41

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Abrasive Wear Behaviour of Conventional and Nanocomposite HVOF-sprayed WC-Co Coatings, Wear, 1999, 225-229, p 789-798

P. Suresh Babu, B. Basu, and G. Sundararajan, Processing-Structure-Property Correlation and Decarburization Phenomenon in Detonation Sprayed WC-12Co Coatings, Acta Mater., 2008, 56, p 5012-5026

H.L.de Villiers Lovelock, Powder/Processing/Structure Relationships in WC-Co Thermal Spray Coatings: A Review of the Published Literature, J. Therm. Spray Technol., 1998, 7, p 357-373.

K. Jia, T.E. Fischer, and B. Gallois, Microstructure, Hardness and Toughness of Nanostructured and Conventional WC-Co Composites, Nanostruct. Mater., 1998, 10, p 875-891

K. Jia, and T.E. Fischer, Abrasion Wear Resistance of Nanostructured and Conventional Cemented Carbides, Wear, 1996, 200, p 206-214

K. Jia, and T.E. Fischer, Sliding Wear of Conventional and Nanostructured Cemented Carbides, Wear, 1997, 203-204, p 310-318

J. He and J.M. Schoenung, A Review on Nanostructured WC-Co Coatings, Surf. Coat. Technol., 2002, 157, p 72-79

H. Chen, G. Gou, M. Tu, and Y. Liu, Characteristics of Nano Particles and Their Effect on the Formation of Nanostructures in air Plasma Spraying WC-17Co Coating, Surf. Coat. Technol., 2009, 203, p 1785-1789

C. Verdon, A. Karimi, and J.L. Martin, A Study of High Velocity Oxy-fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mat. Sci. Eng., 1998, A246, p 11-24.

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Microstructural Evaluation in Thermally Sprayed WC-Co Coatings: Comparison between Nanocomposite and Conventional Starting Powders, Acta Mater., 2000, 48, p 1593-1604

C.J. Li, A. Ohmori, and Y. Harada, Formation of an Amorphous Phase in Thermal Sprayed WC-Co, J. Therm. Spray Technol., 1996, 5, p 69-73

Q. Yang, T. Senda, and A. Ohmori, Effect of Carbide Grain Size on Microstructure and Sliding Wear Behaviour of HVOF-sprayed WC-12%Co Coatings, Wear, 2003, 254, p 23-34

S. Usmani, S. Sampath, D.L. Houck, and D. Lee, Effect of Carbide Grain Size on the Sliding and Abrasive Wear Behaviour of Thermal Sprayed WC-Co Coatings, Trib. Trans., 1997, 40, p 470-478.

C.-J. Li, A. Ohmori, and K. Tani, Effect of WC Particle Size on the Abrasive Wear of Thermally Sprayed WC-Co Coatings, Mater. Manuf. Process., 1999, 14(2), p 175-184

Z.X. Ding, Q. Wang, and Z.L. Liu, Performance Study of Erosion Wear of Nano Structured WC-12Co Coatings Sprayed by HVOF, Key Eng. Mater., 2008, 373-374, p 27-30

J.M. Guilemany, S. Dosta, J. Nin, and J.R. Miguel, Study of the Properties of WC-Co Nanostructured Coatings Sprayed by High-Velocity Oxyfuel, J. Therm. Spray Technol., 2005, 14, p 405-413

A.H. Dent, S. DePalo, and S. Sampath, Examination of the Wear Properties of HVOF Sprayed Nanostructured and Conventional WC-Co Cermets with Different Binder Phase Contents, J. Therm. Spray Technol., 2002, 11, p 551-558

P.H. Shipway, D.G. McCartney, and T. Sudaprasert, Sliding Wear Behaviour of Conventional and Nanostructured HVOF Sprayed WC-Co Coatings, Wear, 2005, 259, p 820-827

X.Q. Zhao, H.D. Zhou, and J.M. Chen, Comparative Study of the Friction and Wear Behaviour of Plasma Sprayed Conventionl and Nanostructured WC-12%Co Coatings on Stainless Steel, Mat. Sci. Eng., 2006, 431, p 29-297

G. Di Girolamo, F. Marra, G. Pulci, J. Tirillo, T. Valente, and L. Pilloni, Microstructure and Wear Behavior of Plasma-Sprayed Nanostructured WC-Co Coatings, Int. J. Appl. Ceram. Technol., 2013, 10, p 60-71

C. Bartuli, T. Valente, F. Cipri, E. Bemporad, and M. Tului, Parametric study of a HVOF process for the deposition of nanostructured WC-Co coatings, J. Therm. Spray Technol., 2005, 14, p 187-195

G. James, Berryman, Elastic and Transport Properties in Polycrystals of Cracked Grains: Cross-property Relations and Microstructure, Int. J. Eng. Sci., 2008, 46, p 500-512

L. Shen and J. Li, A Numerical Simulation for Effective Elastic Moduli of Plates with Various Distributions and Sizes of Cracks, Int. J. Solids Struct., 2004, 41, p 7471-7492

D.K. Shetty, I.G. Wright, P.N. Mincer, and A.H. Clauer, Indentation Fracture of WC-Co Cermets, J. Mat. Sci., 1985, 20, p 1873-1882

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus using Load and Displacement Sensing Indentation, J. Mater. Res., 1992, 7(6), p 1564-1583

ASTM G65-04, Standard test method for measuring abrasion using the dry sand rubber wheel apparatus

ASTM G76-07, Standard test method for conducting erosion tests by solid particle impingement using gas jets

F.H. Chung, Quantitative Interpretation of X-ray Diffraction Patterns of Mixtures-II: Adiabatic Principle of X-ray Diffraction Analysis of Mixtures, J. Appl. Cryst., 1974, 7, p 526

S. Dosta, and J.M. Guilemany, Personal communiction, 2007.

Metals Hand Book, Properties and Selection: Non-Ferrous Alloys and Special Purpose Materials, 10th ed, ASM International, 1990, p 2,

ASM Engineered Material Reference Book, 2nd ed., M. Bauccio, Ed., ASM International, Materials Park, OH, 1994

E. Kadyrov, Gas-Particle Interaction in Detonation Spraying Systems, J. Therm. Spray Technol., 1996, 5, p 185-195

E.C. David, and R.W. Zimmerman, Elastic Moduli of Solids Containing Spheroidal Pores, Int. J. Eng. Sci., 2011, 49, p 544-560

M. Landa, F. Kroupa, K. Neufuss, and P. Urbanek, Effect of Uniaxial Progress on Ultrasound Velocities and Elastic Moduli in Plasma-sprayed Ceramics, J. Therm. Spray Technol., 2003, 12, p 226-233

G. Sundararajan, M. Roy, and B. Venkataraman, Erosion Efficiency—a New Parameter to Characterize the Dominant Erosion Mechanism, Wear, 1990, 140, p 369-381

A.J. Allen, J. Ilavsky, G.G. Long, J.S. Wallace, C.C. Berndt, and H. Herman, Microstructural Characterization of Yttria Stabilized Zirconia Plasma-sprayed Deposits using Multiple Small Angle Neutron Scattering, Acta Mater., 2001, 49, p 1661-1675

A. Kulkarni, Z. Wang, T. Nakamura, S. Sampath, A. Goland, H. Herman, J. Allen, J. Ilavsky, G. Long, J. Frahm, and R.W. Steinbrech, Comprehensive Microstructural Characterization and Predictive Property Modeling Of Plasma-sprayed Zirconia Coatings, Acta Mater., 2003, 51, p 2457-2475

Z. Wang, A. Kulkarni, S. Deshpande, T. Nakamura, and H. Herman, Effects of Pores and Interfaces on Effective Properties of Plasma Sprayed Zirconia Coatings, Acta Mater., 2003, 51, p 5319-5334

S. Deshpande, A. Kulkarni, S. Sampath, and H. Herman, Application of Image Analysis for Characterization of Porosity in Thermal Spray Coatings and Correlation with Small Angle Neutron Scattering, Surf. Coat. Technol., 2004, 187, p 6-16

G. Sundararajan, N.M. Chavan, G. Sivakumar, and P. Sudharshan Phani, Evaluation of Parameters for Assessment of Inter-splat Bond Strength in Cold-sprayed Coatings, J. Thermal Spray Technol., 2010, 19, p 1255-1266.

Acknowledgments

The authors wish to thank the Director, ARCI for permission to publish this article. Suresh Babu would like to thank center for engineered coatings for extending their support in making available coating deposition and wear test facilities and Dr K Radha for carbon analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pitchuka, S.B., Basu, B. & Sundararajan, G. A Comparison of Mechanical and Tribological Behavior of Nanostructured and Conventional WC-12Co Detonation-Sprayed Coatings. J Therm Spray Tech 22, 478–490 (2013). https://doi.org/10.1007/s11666-013-9901-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9901-3