Abstract

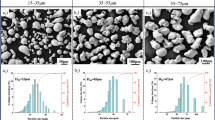

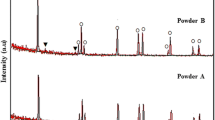

The effects of commercially pure titanium particle morphology (spherical, sponge, and irregular) and size distributions (mean particle sizes of 20-49 μm) on the cold spray process and resulting coating properties were investigated. Numerous powder and coating characterizations were performed including: powder oxygen and nitrogen contents, powder flowability, powder compressibility, coating microhardness, coating porosity, LOM/SEM analyses, and XRD. Compared to spherical powders, the sponge and irregular CP-Ti powders had higher oxygen content, poorer powder flowability, higher compression ratio, lower powder packing factor, and higher average particle impact velocities. XRD results showed no new phases present when comparing the various feedstock powders to corresponding coatings. A higher particle temperature was also obtained with larger particle size for all feedstock powder morphologies processed with the same set of spray parameters. A spherical powder with 29 μm mean particle size was found to have the lowest porosity coating and best cold sprayability. The relationships of several as-cold sprayed coating characteristics to the ratio of particle impact and critical velocities were also discussed.

Similar content being viewed by others

References

V.K. Champagne, The Cold Spray Deposition Process: Fundamentals and Applications, Woodhead Publishing Ltd, Cambridge, 2007

R.G. Maev and V. Leshchynsky, Introduction to Low Pressure Gas Dynamic Spray: Physics & Technology, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2008

A. Papyrin, V. Kosarev, K.V. Klinkov, and V.M. Fomin, Cold Spray Technology, Elsevier Ltd., Oxford, 2006

E. Irissou, J.G. Legoux, A.N. Ryabinin, B. Jodoin, and C. Moreau, Review on Cold Spray Process and Technology: Part I—Intellectual Property, J. Therm. Spray Technol., 2008, 17(4), p 495-516

T. Schmidt, H. Assadi, F. Gartner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

J. Kawakita, H. Katanoda, M. Watanabe, K. Yokoyama, and S. Kuroda, Warm Spraying: An Improved Spray Process to Deposit Novel Coatings, Surf. Coat. Technol., 2008, 202(18), p 4369-4373

G. Bae, K. Kang, J.-J. Kim, and C. Lee, Nanostructure Formation and Its Effects on the Mechanical Properties of Kinetic Sprayed Titanium Coating, Mater. Sci. Eng. A, 2010, 527(23), p 6313-6319

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H.J. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57(19), p 5654-5666

K. Kim, M. Watanabe, J. Kawakita, and S. Kuroda, Grain Refinement in a Single Titanium Powder Particle Impacted at High Velocity, Scripta Mater., 2008, 59(7), p 768-771

K. Kim and S. Kuroda, Amorphous Oxide Film Formed by Dynamic Oxidation During Kinetic Spraying of Titanium at High Temperature and Its Role in Subsequent Coating Formation, Scripta Mater., 2010, 63(2), p 215-218

K. Kim, M. Watanabe, K. Mitsuishi, K. Iakoubovskii, and S. Kuroda, Impact Bonding and Rebounding Between Kinetically Sprayed Titanium Particle and Steel Substrate Revealed by High-Resolution Electron Microscopy, J. Phys. D: Appl. Phys., 2009, 42(6), p 5p

C.J. Li and W.Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167, p 278-283

S.H. Zahiri, C.I. Antonio, and M. Jahedi, Elimination of Porosity in Directly Fabricated Titanium Via Cold Gas Dynamic Spraying, J. Mater. Process. Technol., 2009, 209(2), p 922-929

S.H. Zahiri, S.C. Mayo, and M. Jahedi, Characterization of Cold Spray Titanium Deposits by X-Ray Microscopy and Microtomography, Microsc. Microanal., 2008, 14(3), p 260-266

S.H. Zahiri, W. Yang, and M. Jahedi, Characterization of Cold Spray Titanium Supersonic Jet, J. Therm. Spray Technol., 2009, 18(1), p 110-117

S. Gullzia, B. Tiganis, M.Z. Jahedi, N. Wright, T. Gengenbach, and C. MacRae, Effects of Cold Spray Process Gas Temperature on CP Titanium Structure, Thermal Spray 2009: Expanding Thermal Spray Performance to New Markets and Applications, B. Marple, M. Hyland, Y.-C. Lau, C.J. Li, R.S. Lima, and G. Montavon, Ed., 2009, p 237-242

T. Marrocco, D.G. McCartney, P.H. Shipway, and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

D. Rafaja, T. Schucknecht, V. Klemm, A. Paul, and H. Berek, Microstructural Characterisation of Titanium Coatings Deposited Using Cold Gas Spraying on Al2O3 Substrates, Surf. Coat. Technol., 2009, 203(20-21), p 3206-3213

J. Karthikeyan, C.M. Kay, J. Lindeman, R.S. Lima, and C. Berndt, Cold Spray Processing of Titanium Powder, Thermal Spray: Surface Engineering via Applied Research, C. Berndt, Ed., 2000, p 255-262

T. Hussain, Cold Spraying of Titanium: A Review of Bonding Mechanisms, Microstructure and Properties, Key Eng. Mater., 2013, 533, p 53-90

S.H. Zahiri, D. Fraser, and M. Jahedi, Recrystallization of Cold Spray-Fabricated CP Titanium Structures, J. Therm. Spray Technol., 2009, 18(1), p 16-22

W. Wong, E. Irissou, A. Ryabinin, J.-G. Legoux, and S. Yue, Influence of Helium and Nitrogen Gases on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2011, 20(1), p 213-226

N. Cinca, M. Barbosa, S. Dosta, and J.M. Guilemany, Study of Ti Deposition onto Al Alloy by Cold Gas Spraying, Surf. Coat. Technol., 2010, 205(4), p 1096-1102

H. Assadi, T. Schmidt, H. Richter, J.O. Kliemann, K. Binder, F. Gärtner, T. Klassen, and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

S. Gulizia, A. Trentin, S. Vezzù, S. Rech, P. King, M. Jahedi, and M. Guagliano, Characterisation of Cold Spray Titanium Coatings, Mater. Sci. Forum, 2010, 654-656, p 898-901

W. Wong, A. Rezaeian, S. Yue, E. Irissou, and J.G. Legoux, Effects of Gas Temperature, Gas Pressure, and Particle Characteristics on Cold Sprayed Pure Titanium Coatings, Thermal Spray 2009: Expanding Thermal Spray Performance to New Markets and Applications, B. Marple, M. Hyland, Y.-C. Lau, C.J. Li, R.S. Lima, and G. Montavon, Ed., 2009, p 231-236

R.E. Blose, B.H. Walker, R.M. Walker, and S.H. Froes, New Opportunities to Use Cold Spray Process for Applying Additive Features to Titanium Alloys, Met. Powder Rep., 2006, 61(9), p 30-37

D. Christoulis, S. Guetta, V. Guipont, and M. Jeandin, The Influence of the Substrate on the Deposition of Cold-Sprayed Titanium: An Experimental and Numerical Study, J. Therm. Spray Technol., 2011, 20(3), p 523-533

E. Baril, L.P. Lefebvre, and Y. Thomas, Interstitials Sources and Control in Titanium Pm Processes, PM2010 Powder Metallurgy World Congress (CD-Rom), European Powder Metallurgy Association, 2010, p 1-8

D.M. Brunette, P. Tengvall, M. Textor, and P. Thomsen, Titanium in Medicine, Springer, Berlin, 2001

S.R. Lampman, Compressibility and Compactibility of Metal Powders, ASM Handbook Volume 7: Powder Metal Technologies and Applications, 10 ed., S.R. Lampman Ed., ASM International, 1998, p 708-716

E. Irissou, J.-G. Legoux, B. Arsenault, and C. Moreau, Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties, J. Therm. Spray Technol., 2007, 16(5), p 661-668

T. Stoltenhoff, H. Kreye, and H.J. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Therm. Spray Technol., 2002, 11(4), p 542-550

C.B. Henderson, Drag Coefficients of Spheres in Continuum and Rarefied Flows, AIAA J., 1976, 14(6), p 707-708

A. Haider and O. Levenspiel, Drag Coefficient and Terminal Velocity of Spherical and Nonspherical Particles, Powder Technol., 1989, 58(1), p 63-70

T. Schmidt, F. Gartner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

K. Mailhot, F. Gitzhofer, and M.I. Boulos, Absolute Coating Porosity Measurement Using Image Analysis, Thermal Spray 1998: Meeting the Challenges of the 21st Century, C. Coddet, Ed., ASM International, Materials Park, OH, 1998, p 917-922

S. Deshpande, A. Kulkarni, S. Sampath, and H. Herman, Application of Image Analysis for Characterization of Porosity in Thermal Spray Coatings and Correlation with Small Angle Neutron Scattering, Surf. Coat. Technol., 2004, 187(1), p 6-16

P.C. King and M. Jahedi, Relationship Between Particle Size and Deformation in the Cold Spray Process, Appl. Surf. Sci., 2010, 256(6), p 1735-1738

L.V.M. Antony and R.G. Reddy, Processes for Production of High-Purity Metal Powders, JOM, 2003, 55(3), p 14-18

M.J. Donachie, Titanium: A Technical Guide, 2nd ed., ASM International, Materials Park, OH, 2000

W. Carson and B.H. Pittenger, Bulk Properties of Powders, ASM Handbook Volume 7: Powder Metal Technologies and Applications, 10th ed., S.R. Lampman, Ed., ASM International, Materials Park, OH, 1998, p 677-686

W. Wong, A. Rezaeian, E. Irissou, J.G. Legoux, and S. Yue, Cold Spray Characteristics of Commercially Pure Ti and Ti-6Al-4V, Adv. Mater. Res., 2010, 89-91, p 639-644

R. Guinebretière, X-Ray Diffraction by Polycrystalline Materials, ISTE Ltd., London, 2007

H. Gruner, P. Gruner, and J. Moens, Optimized Powder Feeding, a Key Parameter for Thermal Spraying, Thermal Spray 2005: Thermal Spray Connects: Explore Its Surfacing Potential!, E. Lugscheider, Ed., ASM International, Materials Park, OH, 2005, p 1558-1560

R.C. Dykhuizen and R.A. Neiser, Optimizing the Cold Spray Process, Thermal Spray 2003: Advancing the Science & Applying the Technology, C. Moreau and B. Marple, Ed., ASM International, Materials Park, OH, 2003, p 19-26

T.C. Jen, L. Li, W. Cui, Q. Chen, and X. Zhang, Effects of Shock Waves on the Particle Acceleration for Cold Gas Dynamic Spray, Am. Soc. Mech. Eng., Heat Transfer Division, (Publication) HTD, Article number IMECE2004-60723, 2004, 375(3), p 499-505

X. Luo and H. Olivier, Gas Dynamic Principles and Experimental Investigations of Shock Tunnel Produced Coatings, J. Therm. Spray Technol., 2009, 18(4), p 546-554

J. Pattison, S. Celotto, A. Khan, and W. O’Neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surf. Coat. Technol., 2008, 202(8), p 1443-1454

C.J. Li, H.T. Wang, Q. Zhang, G.J. Yang, W.Y. Li, and H.L. Liao, Influence of Spray Materials and Their Surface Oxidation on the Critical Velocity in Cold Spraying, J. Therm. Spray Technol., 2010, 19(1-2), p 95-101

W.Y. Li, C.J. Li, and H. Liao, Significant Influence of Particle Surface Oxidation on Deposition Efficiency, Interface Microstructure and Adhesive Strength of Cold-Sprayed Copper Coatings, Appl. Surf. Sci., 2010, 256(16), p 4953-4958

L.P. Lefebvre and E. Baril, Effect of Oxygen Concentration and Distribution on the Compression Properties on Titanium Foams, Adv. Eng. Mater., 2008, 10(9), p 868-876

H. Conrad, Effect of Interstitial Solutes on the Strength and Ductility of Titanium, Prog. Mater. Sci., 1981, 26(2-4), p 123-403

Acknowledgments

The cold spray equipment used for this study was funded by CFI project number 8246, McGill University (Montreal, Canada) with the support of Cold Gas Technology GmbH, Tecnar Automation Ltd., and Polycontrols Technologies Inc. The authors acknowledge the support of NSERC strategic grant and would like to thank J.F. Alarie, F. Belval, B. Harvey, M. Lamontagne, M. Laplume, J. Sykes, M. Thibodeau, and J.C. Tremblay from NRC for their technical support. Additional appreciation goes toward Dr. E. Baril and Dr. Y. Thomas for their insightful comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wong, W., Vo, P., Irissou, E. et al. Effect of Particle Morphology and Size Distribution on Cold-Sprayed Pure Titanium Coatings. J Therm Spray Tech 22, 1140–1153 (2013). https://doi.org/10.1007/s11666-013-9951-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9951-6