Abstract

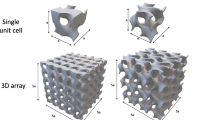

This work focuses on the study of the adhesion and thermal performance of near-net-shaped pyramidal fin arrays manufactured by cold spray on aluminum alloy substrate coated with various bond coats: a cold-sprayed bond coat as well as nitrogen- and air-propelled arc-sprayed bond coats. Furthermore, the effects of the fin density, fin height, and substrate surface roughness on the adhesion strength of the fins deposited on Al6061 substrates were characterized. It was found that the fin density, the fin height, and the substrate roughness have little impact on the adhesion strength of this system. The adhesion strength was found to be inversely proportional to the surface hardness when investigating these parameters for the different thermal-spray bond coatings, with all the fin systems having a much greater strength than the theoretical application stresses. Finally, it was found that the increase in the fin’s base layer’s roughness increases the overall heat transfer, with the bond coat material having a negligible effect on the thermal resistance for this type of heat-exchanger configuration.

Similar content being viewed by others

Abbreviations

- \(\Delta P_{\text{fin}}\) :

-

Fin differential pressure [Pa]

- \(\Delta T_{1}\) :

-

Inlet temperature difference [K]

- \(\Delta T_{2}\) :

-

Outlet temperature difference [K]

- \(\Delta T_{\text{lm}}\) :

-

Log mean temperature difference [K]

- \(\varepsilon\) :

-

Relative surface roughness

- \(\eta\) :

-

Fan efficiency

- \(\rho\) :

-

Fluid density [kg/m3]

- \(\tau_{\text{d}}\) :

-

Fluid drag shear stress [Pa]

- \(A_{\text{base}}\) :

-

Base area [m2]

- \(A_{\text{cond}}\) :

-

Conduction area [m2]

- \(A_{\text{conv}}\) :

-

Convection area [m2]

- \(A_{\text{front}}\) :

-

Frontal area [m2]

- \(C_{\text{d}}\) :

-

Drag coefficient

- \({\text{Cp}}\) :

-

Fluid’s specific heat capacity \([ {\text{kJ/(kg}} \, {\rm{K}})]\)

- \(D_{\text{h}}\) :

-

Hydraulic diameter [m]

- \(e_{\text{v}}\) :

-

Pumping power per unit volume [kW/m3]

- \(H\) :

-

Fin height [m]

- \(h\) :

-

Convective heat-transfer coefficient [W/(m2 · K)]

- \(k\) :

-

Thermal conductivity [W/(m · K)]

- \(L\) :

-

Base length (streamwise direction) [m]

- \(\dot{m}\) :

-

Mass-flow rate [kg/s]

- \(q\) :

-

Heat flux [W/m2]

- \(R_{\text{cond}}\) :

-

Conduction thermal resistance [K/W]

- \(R_{\text{conv}}\) :

-

Convection thermal resistance [K/W]

- \(R_{\text{eq}}\) :

-

Equivalent thermal resistance [K/W]

- \(r\) :

-

Surface roughness [m]

- \(T_{\text{in}}\) :

-

Inlet fluid temperature [K]

- \(T_{\text{out}}\) :

-

Outlet fluid temperature [K]

- \(t\) :

-

Conduction length [m]

- \(U\) :

-

Fluid velocity [m/s]

- \({\text{UA}}_{\text{conv}}\) :

-

Convection thermal conductance [W/K]

- \({\text{UA}}_{v}\) :

-

Thermal conductance per unit volume \([ {\text{kW/(m}}^{ 3} {\text{ K)]}}\)

- \(V\) :

-

Volume [m3]

- \(\dot{V}_{f}\) :

-

Volumetric flow rate [m3/s]

References

A.B. Lovins, Small is Profitable: The Hidden Economic Benefits of Making Electrical Resources the Right Size, Rocky Mountain Institute, 2002

S.M. Kaplan and F. Sissine, Smart Grid: Modernizing Electric Power Transmission and Distribution; Energy Independence, Storage and Security; Energy Independence and Security Act … and Resiliency; Integra, TheCapitol.Net Inc., Alexandria, 2009

D. Bohn, Micro Gas Turbine and Fuel Cell: A Hybrid Energy Conversion System with High Potential, NATO Research and Technology Organisation, 2005

J. Tian, T. Kim, T.J. Lu, H.P. Hodson, D.T. Queheillalt, D.J. Sypeck, and H.N.G. Wadley, The Effects of Topology Upon Fluid-Flow and Heat-Transfer Within Cellular Copper Structures, Int. J. Heat Mass Transf., 2004, 47(14–16), p 3171-3186

Z. Anxionnaz, M. Cabassud, C. Gourdon, and P. Tochon, Heat Exchanger/Reactors (HEX Reactors): Concepts, Technologies: State-of-the-Art, Chem. Eng. Process., 2008, 47(12), p 2029-2050

R.L. Shaner, Heat Exchanger Having Metal Wire Screens, and Method of Making Stack of Screens Therefor, US4840228, Year of Priority (Issued): 1985 (1989)

J. Chisholm, Method of Making a Crimped Wire Mesh Heat Exchanger/Sink, US4843693, Year of Priority (Issued): 1988 (1989)

J. Assaad, A. Corbeil, P. Richer, and B. Jodoin, Novel Stacked Wire Mesh Compact Heat Exchangers Produced Using Cold Spray, J. Therm. Spray Technol., 2011, 20(6), p 1192-1200

Y. Cormier, P. Dupuis, B. Jodoin, and A. Corbeil, Net Shape Fins for Compact Heat Exchanger Produced by Cold Spray, J. Therm. Spray Technol., 2013, 22(7), p 1210-1221

P. Dupuis, Y. Cormier, A. Farjam, B. Jodoin, and A. Corbeil, Performance Evaluation of Near-Net Pyramidal Shaped Fin Arrays Manufactured by Cold Spray, Int. J. Heat Mass Transf., 2014, 69, p 34-43

Y. Cormier, P. Dupuis, A. Farjam, B. Jodoin, and A. Corbeil, Additive Manufacturing of Pyramidal Pin Fins: Height and Fin Density Effects Under Forced Convection, Int. J. Heat Mass Transf., 2014, 75, p 235-244

H.R. Salimi Jazi, J. Mostaghimi, S. Chandra, L. Pershin, and T. Coyle, Spray-Formed, Metal-Foam Heat Exchangers for High Temperature Applications, J. Thermal Sci. Eng. Appl., 2009, 1(3), p 1-7

F. Azarmi, J. Saaedi, T.W. Coyle, and J. Mostaghimi, Microstructure Characterization of Alloy 625 Deposited on Nickel Foam Using Air Plasma Spraying, Adv. Eng. Mater., 2008, 10(5), p 459-465

J.G. Legoux and S. Dallaire, Adhesion Mechanisms of Arc-Sprayed Zinc on Concrete, J. Therm. Spray Technol., 1995, 4(4), p 395-400

X. Wang, J. Heberlein, E. Pfender, and W. Gerberich, Effect of Nozzle Configuration, Gas Pressure, and Gas Type on Coating Properties in Wire Arc Spray, J. Therm. Spray Technol., 1999, 8(4), p 565-575

R. Drehmann, T. Grund, T. Lampke, B. Wielage, K. Manygoats, T. Schucknecht, and D. Rafaja, Splat Formation and Adhesion Mechanisms of Cold Gas-Sprayed Al Coatings on Al2O3 Substrates, J. Therm. Spray Technol., 2014, 23(1–2), p 68-75

D.J. Varacalle, D.P. Guillen, D.M. Deason, W. Rhodaberger, and E. Sampson, Effect of Grit-Blasting on Substrate Roughness and Coating Adhesion, J. Therm. Spray Technol., 2006, 15(3), p 348-355

M. Yandouzi, A.J. Böttger, R.W.A. Hendrikx, M. Brochu, P.F. Richer, A. Charest, and B. Jodoin, Microstructure and Mechanical Properties of B4C Reinforced Al-Based Matrix Composite Coatings Deposited by CGDS and PGDS Processes, Surf. Coat. Technol., 2010, 205, p 2234-2246

EN 15340, European Standard Method-Determination of Shear Load Resistance of Thermally Sprayed Coatings, 2007, p. A91

J.R. Davis, Ed., Handbook of Thermal Spray Technology, ASM International, 2004

P.H. Shipway, D.G. McCartney, and T. Sudaprasert, Sliding Wear Behaviour of Conventional and Nanostructured HVOF Sprayed WC-Co Coatings, Wear, 2005, 259(7–12), p 820-827

S. Naik, S.D. Probert, and M.J. Shilston, Forced Convective Steady-State Heat Transfers From Shrouded Vertical Fin Arrays Aligned Parallel to an Undisturbed Air-Stream, Appl. Energy, 1987, 26, p 137-158

J.J. Hwang and T.M. Liou, Heat Transfer and Friction in a Low-Aspect-Ratio Rectangular Channel with Staggered Perforated Ribs on Two Opposite Walls, ASME J. Heat Transfer, 1995, 117(11), p 843-850

R.W. Fox, P.J. Pritchard, and A.T. McDonald, Introduction to Fluid Mechanics, 7th ed., Wiley, Hoboken, NJ, 2008

N. Sahiti, F. Durst, and A. Dewan, Heat Transfer Enhancement by Pin Elements, Int. J. Heat Mass Transf., 2005, 48, p 4738-4747

N. Sahiti, F. Durst, and A. Dewan, Strategy for Selection of Elements for Heat Transfer Enhancement, Int. J. Heat Mass Transf., 2006, 49, p 3392-3400

Acknowledgment

The authors would like to thank the MITACS Accelerate program for the financial support to this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cormier, Y., Dupuis, P., Jodoin, B. et al. Mechanical Properties of Cold Gas Dynamic-Sprayed Near-Net-Shaped Fin Arrays. J Therm Spray Tech 24, 476–488 (2015). https://doi.org/10.1007/s11666-014-0203-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0203-1