Abstract

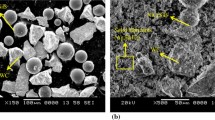

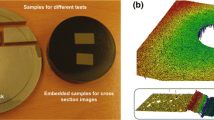

In order to improve the tribological properties of aluminum alloy cylinders and cylinder bore walls, WC-reinforced Ni-WC coatings were deposited on an aluminum substrate by atmospheric plasma spraying. The composition and microstructure of Ni-WC coatings with different WC contents were investigated and the tribological properties were tested under oil lubrication, lean oil lubrication and dry friction. The results showed that Ni-WC coatings consisted of a lamellar structure. Friction and wear testing results demonstrated that Ni-WC coatings had much better tribological performance than gray cast iron under different lubricating conditions. These Ni-WC composite coatings exhibited excellent mechanical properties and tribological properties due to the strengthening effect of the WC phase.

Similar content being viewed by others

References

A. Edrisy, T. Perry, and A.T. Alpas, Investigation of Scuffing Damage in Aluminum Engines with Thermal Spray Coatings, Wear, 2005, 259, p 1056-1062

S. Johansson, C. Frennfelt, A. Killinger, P.H. Nilsson, R. Ohlsson, and B.G. Rosén, Frictional Evaluation of Thermally Sprayed Coatings Applied on the Cylinder Liner of a Heavy Duty Diesel Engine: Pilot Tribometer Analysis and Full Scale Engine Test, Wear, 2011, 273, p 82-92

K. Bobzin, F. Ernst, K. Richardt, T. Schlaefer, C. Verpoort, and G. Flores, Thermal Spraying of Cylinder Bores with the Plasma Transferred Wire Arc Process, Surf. Coat. Technol., 2008, 202, p 4438-4443

M. Wenzelburger, Modeling of Thermally Sprayed Coatings on Light Metal Substrates: Layer Growth and Residual Stress Formation, Surf. Coat. Technol., 2004, 180–181, p 429-435

T.M. Yonushonis, Overview of Thermal Barrier Coatings in Diesel Engines, J. Therm. Spray Technol., 1997, 6, p 50-56

B. Hwang, S. Lee, and J. Ahn, Effect of Oxides on Wear Resistance and Surface Roughness of Ferrous Coated Layers Fabricated by Atmospheric Plasma Spraying, Mater. Sci. Eng. A, 2002, 335, p 268-280

B. Gérard, Application of Thermal Spraying in the Automobile Industry, Surf. Coat. Technol., 2006, 201, p 2028-2031

Y. Wang, C. Yao, G. Barber, B. Zhou, and Q. Zou, Scuffing Resistance of Coated Piston Skirts Run Against Cylinder Bores, Wear, 2005, 259, p 1041-1047

G. Barbezat, Advanced Thermal Spray Technology and Coating for Lightweight Engine Blocks for the Automotive Industry, Surf. Coat. Technol., 2005, 200, p 1990-1993

S.L. Liu and X.P. Zheng, Microstructure and Properties of AC-HVAF Sprayed Ni60/WC Composite Coating, J. Alloy. Compd., 2009, 480, p 254-258

T. Yu, Q.L. Deng, J.F. Zheng, G. Dong, and J.G. Yang, Microstructure and Wear Behaviour of Laser Clad NiCrBSi+ Ta Composite Coating, Surf. Eng., 2012, 28, p 357-363

H. Chen, K. Feng, J. Xiong, and Z. Guo, Characterization and Stress Relaxation of the Functionally Graded WC-Co/Ni Component/Stainless Steel Joint, J. Alloy. Compd., 2013, 557, p 18-22

T. Liyanage, G. Fisher, and A.P. Gerlich, Microstructures and Abrasive Wear Performance of PTAW Deposited Ni-WC Overlays Using Different Ni-Alloy Chemistries, Wear, 2012, 274-275, p 345-354

S.-P. Lu, O.-Y. Kwon, and Y. Guo, Wear Behavior of Brazed WC/NiCrBSi (Co) Composite Coatings, Wear, 2003, 254, p 421-428

T. Ungár, Microstructural Parameters from X-Ray Diffraction Peak Broadening, Scripta Mater., 2004, 51, p 777-781

S. Sampath and H. Herman, Rapid Solidification and Microstructure Development During Plasma Spray Deposition, J. Therm. Spray Technol., 1996, 5, p 445-456

P. Kotalik and K. Volenik, Cooling Rates of Plasma-Sprayed Metallic Particles in Liquid and Gaseous Nitrogen, J. Phys. D Appl. Phys., 2001, 34, p 567-573

M.R. Libera, P.P. Bolsaitis, R.E. Spjut, and J.B. Vandersande, Liquid Supercoolings and Droplet Cooling Rates of Remelted Argon-Atomized Fe-30Ni Powder Particles, J. Mater. Res., 1988, 3, p 441-452

W. Ni, Y.-T. Cheng, M.J. Lukitsch, A.M. Weiner, L.C. Lev, and D.S. Grummon, Effects of the Ratio of Hardness to Young’s Modulus on the Friction and Wear Behavior of Bilayer Coatings, Appl. Phys. Lett., 2004, 85, p 4028-4030

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, Wear, 2000, 246, p 1-11

J. Rech, A. Kusiak, and J.L. Battaglia, Tribological and Thermal Functions of Cutting Tool Coatings, Surf. Coat. Technol., 2004, 186, p 364-371

W. Grzesik, Friction Behaviour of Heat Isolating Coatings in Machining: Mechanical, Thermal and Energy-Based Considerations, Int. J. Mach. Tools Manuf, 2003, 43, p 145-150

J.A. Nairn, Analytical Fracture Mechanics Analysis of the Pull-Out Test Including the Effects of Friction and Thermal Stresses, Adv. Compos. Lett., 2000, 9, p 373-383

Acknowledgments

The authors acknowledge the financial supports by the National Basic Research Program of China (Grant No. 2014CB643302), China Postdoctoral Science Foundation (Grant No. 2014M551784), Foundation for Selected Postdoctoral Project of Zhejiang Province (Grant No. BSH1401040), Ningbo Municipal Nature Science Foundation (Grant No. 2011A610121), Zhejiang Provincial Innovation Team (Grant No. 2011R50006), and Ningbo Municipal Innovation Team (Grant No.2011B81001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, X., Zhu, L., Zhou, Z. et al. Tribological Properties of WC-Reinforced Ni-Based Coatings Under Different Lubricating Conditions. J Therm Spray Tech 24, 1323–1332 (2015). https://doi.org/10.1007/s11666-015-0290-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0290-7