Abstract

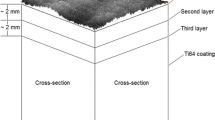

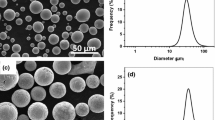

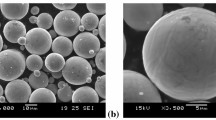

A cold spray process was used to deposit titanium (Ti) coatings of different thicknesses on commercial Ti-6Al-4V (Ti64) substrates. The hardness of the Ti coatings was measured using a Vickers micro-indenter. It was found that the thicker Ti coatings had higher hardness probably due to the better uniformity and higher density of the coatings. The tribological results showed that the friction and wear of the Ti coatings tested against a steel ball under dry condition became lower with higher thickness probably due to the higher wear resistance of the thicker coatings associated with their higher hardness. The specific wear rates of all the Ti coatings were significantly lower than that of the Ti64 substrate as a result of the higher wear resistance of the Ti coatings associated with their cold-worked microstructures and the formation of high wear resistant oxide layers on their wear tracks during the wear testing.

Similar content being viewed by others

References

L. Shen, L.Y. Kong, T.Y. Xiong, H. Du, and T.F. Li, Preparation of TiAl3-Al Composite Coating by Cold Spraying, Trans. Nonferrous Met. Soc. China, 2009, 19, p 879-882

C. Leyens and H. Gedanitz, Long-Term Oxidation of Orthorhombic Alloy Ti-22Al-25Nb in Air Between 650 and 800 °C, Scr. Mater., 1999, 41(8), p 901-906

A. Ralison, G. Dettemwamger, and M. Schutze, Oxidation of Orthorhombic Ti2AlNb Alloys at 800 °C in Air, Mater. Corros., 2000, 51(5), p 317-328

N.W. Khun, R.T. Li, K. Loke, and K.A. Khor, Effects of Al-Cr-Fe Quasicrystal Content on Tribological Properties of Cold Sprayed Titanium Composite Coatings, Tribol. Trans., 2015, 58(4), p 616-624

H. Singh, T.S. Sidhu, and S.B.S. Kalsi, Cold Spray Technology: Future of Coating Deposition Processes, Frattura ed Integrita Strutturale, 2012, 22, p 69-84

S.V. Klinkov, V.F. Kosarev, and M. Rein, Cold Spray Deposition: Significant of Particle Impact Phenomena, Aerosp. Sci. Technol., 2005, 9, p 582-591

H. Assadi, T. Schmidt, H. Richter, J.O. Kliemann, K. Binder, F. Gartner, T. Klassen, and H. Kreye, On Parameter Selection in Cold Spraying, J. Thermal Spray Technol., 2011, 20(6), p 1161-1176

S.B. Pitchuka, B. Boesl, C. Zhang, D. Lahiri, A. Nieto, G. Sundararajan, and A. Agarwal, Dry Sliding Wear Behavior of Cold Sprayed Aluminum Amorphous/Nanocrystalline Alloy Coatings, Surf. Coat. Technol., 2014, 238, p 118-125

C.J. Li, H.T. Wang, G.J. Yang, and C.G. Bao, Characterization of High Temperature Abrasive Wear of Cold Sprayed FeAl Intermetallic Compound Coating, J. Thermal Spray Technol., 2011, 20(1-2), p 227-233

S.R. Bakshi, D. Wang, T. Price, D. Zhang, A.K. Keshri, Y. Chen, D.G. McCartney, P.H. Shipway, and A. Agarwal, Microstructure and Wear Properties of Aluminium/Aluminium-Silicon Composite Coatings Prepared by Cold Spraying, Surf. Coat. Technol., 2009, 204, p 503-510

N.M. Melendez, V.V. Narulkar, G.A. Fisher, and A.G. McDonald, Effect of Reinforcing Particles on the Wear Rate of Low Pressure Cold Sprayed WC Based MMC Coatings, Wear, 2013, 306(1–2), p 185-195

R. Huang, M. Sone, W. Ma, and H. Fukanuma, The Effect of Heat Treatment on the Mechanical Properties of Cold Sprayed Coatings, Surf. Coat. Technol., 2015, 261, p 278-288

N.W. Khun, E. Liu, G.C. Yang, W.G. Ma, and S.P. Jiang, Structure and Corrosion Behaviour of Platinum/Ruthenium/Nitrogen Doped Diamond-like Carbon Thin Films, J. Appl. Phys., 2009, 106, p 013506

H. Yang, C. Tian, L. Sun, B. Wang, L. Wang, J. Yin, A. Wu, and H. Fu, Small Sized and High Dispersed WN from [SiO4(W3O9)4]4- Clusters Loading on GO-Derived Graphene as Promising Carriers for Methanol Electro-Oxidation, Energy Environ. Sci., 2014, 7, p 1939-1949

M.F. Smith, J.E. Brockmann, R.C. Dykhuizen, D.L. Gilmore, R.A. Neiser, and T.J. Roemer, Cold Spray Direct Fabrication: High Rate, Solid State, Material Consolidation, Mater. Res. Soc. Symp. Proc., 1999, 542, p 65

K. Balani, T. Laha, A. Agarwal, J. Karthikeyan, and N. Munroe, Effect of Carrier Gases on Microstructural and Electrochemical Behaviour of Cold Sprayed 1100 Aluminium Coating, Surf. Coat. Technol., 2005, 195, p 272-279

C.M. Mate, Tribology on the Small Scale: A Bottom Up Approach to Friction, Lubrication and Wear, 1st ed, Oxford University Press, Oxford, 2008

H. Ronkainen, A. Laukkanen, and K. Holmberg, Friction in a Coated Surface Deformed by a Sliding Sphere, Wear, 2007, 263(7–12), p 1315-1323

N.W. Khun, B.C.R. Troconis, and G.S. Frankel, Effects of Carbon Nanotube Content on Adhesion Strength and Wear and Corrosion Resistance of Epoxy Composite Coatings on AA2024-T3, Prog. Org. Coat., 2014, 77(1), p 72-80

P. J. Blau, Friction Science and Technology, Marcel Dekker, New York, 1996

B. Bhushan, Tribology and Mechanics of Magnetic Storage Device, 2nd ed., Springer, New York, 1996

N.W. Khun, R.T. Li, and K.A. Khor, Mechanical and Tribological Properties of Spark Plasma Sintered Titanium Composites Filled with Different Al-Cr-Fe Quasicrystal Content, Tribol. Trans., 2015, 58(5), p 859-866

N.W. Khun, G.S. Frankel, and M. Sumption, Effects of Normal Load, Sliding Speed and Surface Roughness on Tribological Properties of Niobium Under Dry and Wet Conditions, Tribol. Trans., 2014, 57(5), p 944-954

J. Meng, N.H. Loh, B.Y. Tay, G. Fu, and S.B. Tor, Tribological Behavior of 316L Stainless Steel Fabricated by Micro Powder Injection Molding, Wear, 2010, 268(7–8), p 1013-1019

T. Kasai, X.Y. Fu, D.A. Rigney, and A.L. Zharin, Applications of a Non-contacting Kelvin Probe During Sliding, Wear, 1999, 225–229, p 186-1204

L.M. Stark, I. Smid, A.E. Segall, T.J. Eden, and J. Potter, Self-Lubricating Cold-Sprayed Coatings Utilizing Microscale Nickel-Encapsulated Hexagonal Boron Nitride, Tribol. Trans., 2012, 55(5), p 624-630

K.M. Chen, Q.Y. Zhang, X.X. Li, L. Wang, X.H. Cui, and S.Q. Wang, Comparative Study of Wear Behaviors of a Selected Titanium Alloy and AISI, H13 Steel as a Function of Temperature and Load, Tribol. Trans., 2014, 57(5), p 838-845

N.W. Khun, E. Liu, T.W.Y. Adrian, D. Senthilkumar, B. Albert, and D.M. Lal, Effects of Deep Cryogenic Treatment on Mechanical and Tribological Properties of AISI, D3 Tool Steel, Friction, 2015, 3(3), p 234-242

Acknowledgments

Authors are grateful for the financial support from the National Research Foundation (NRF), Rolls-Royce (RR), and Nanyang Technological University (NTU), Singapore, with the NRF-RR-NTU research Grant Number of M-RT3.1, and the project team members from RR, Singapore, Harry Eyre, Anna Tai and Nicholas Weeks for their contributions in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khun, N.W., Tan, A.W.Y. & Liu, E. Mechanical and Tribological Properties of Cold-Sprayed Ti Coatings on Ti-6Al-4V Substrates. J Therm Spray Tech 25, 715–724 (2016). https://doi.org/10.1007/s11666-016-0396-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0396-6