Abstract

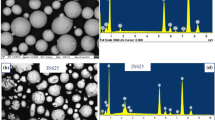

Cold spraying is a coating technology on the basis of aerodynamics and high-speed impact dynamics. Spray particles (usually 1-50 μm in diameter) are accelerated to high velocity (typically 300-1200 m/s) by a high-speed gas (preheated air, nitrogen, or helium) flow that is generated through a convergent-divergent de Laval type nozzle. The coating forms through the intensive plastic deformation of particles impacting on the substrate at temperatures well below the melting point of the spray material. In the present paper, the main processing parameters affecting the crystallization behavior of pure Ni cold spray deposits on IN718 alloy are described. Various experimental conditions have been analyzed: gas temperature and pressure, nozzle to substrate distance. In particular, the study deals with those conditions leading to a strong grain refinement, with an acceptable level of the deposits mechanical properties. In precise spray conditions, a shift toward amorphous phases has been observed and studied. A systematic analysis of microstructural evolution, performed through TEM observations, as a function of processing parameters is presented.

Similar content being viewed by others

References

P. Cavaliere and A. Silvello, Mechanical and Microstructural Behavior of Cold-Sprayed Titanium- and Nickel-Based Coatings, J. Therm. Spray. Technol., 2015, 24(8), p 1506-1512

P. Cavaliere and A. Silvello, Processing Conditions Affecting Residual Stresses and Fatigue Properties of Cold Spray Deposits, Int. J. Adv. Manuf. Technol., 2015, 81(9), p 1857-1862

P. Cavaliere, A. Perrone, and A. Silvello, Mechanical and Microstructural Behavior of Nanocomposites Produced Via Cold Spray, Compos. Part B-Eng., 2014, 67, p 326-331

P. Cavaliere, A. Perrone, and A. Silvello, Processing Conditions Affecting Grain Size and Mechanical Properties in Nanocomposites Produced Via Cold Spray, J. Therm. Spray Technol., 2014, 23(7), p 1089-1096

Y. Zou, W. Quin, E. Irissou, J.G. Legoux, S. Yue, and J.A. Szpunar, Dynamic Recrystallization in the Particle/Particle Interfacial Region of Cold-Sprayed Nickel Coating: Electron Backscattered Diffraction Characterization, Scr. Mater., 2009, 61, p 899-902

Y. Xiong, X. Xiong, S. Yoon, G. Bae, and C. Lee, Dependence of Bonding Mechanisms of Cold Sprayed Coatings on Strain-Rate-Induced Non-Equilibrium Phase Transformation, J. Therm. Spray Technol., 2011, 20, p 860-865

V. Keryvin, V.H. Hoang, and J. Shen, Hardness, Toughness, Brittleness and Cracking Systems in an Iron-Based Bulk Metallic Glass by Indentation, Intermetallics, 2009, 17(4), p 211-217

A. Inoe, B.L. Shen, and C.T. Chang, Super-High Strength of Over 4000 MPa for Fe-Based Bulk Glassy Alloys in [(Fe1-xCox)0.75B0.2Si 0.05]96Nb4 System, Acta Mater., 2004, 52, p 4093-4099

S.J. Pang, T. Zhang, K. Asami, and A. Inoue, Roles of Aluminium and Chromium in Sulfidation and Oxidation of Sputter-Deposited Al- and Cr-Refractory Metal Alloys, Corros. Sci., 2002, 44, p 1847-1856

A. Makino, T. Bitoh, A. Kojima, A. Inoe, and T. Masumoto, Magnetic Properties of Zero-Magnetostrictive Nanocrystalline Fe-Zr-Nb-B Soft Magnetic Alloys with High Magnetic Induction, J. Magn. Mater., 2000, 215-216, p 288-292

M. Trexler and N. Thadhani, Mechanical properties of bulk metallic glasses, Progr. Mater. Sci., 2010, 55, p 759-893

I. Kaban, P. Jovari, A. Waske, M. Stoica, J. Bednarcik, B. Beuneu, N. Mattern, and J. Ecker, Atomic Structure and Magnetic Properties of Fe-Nb-B Metallic Glasses, J. Alloys Comp., 2014, 586, p S189-S193

W.H. Wang, C. Dong, and C.H. Shek, Bulk Metallic Glasses, Mater. Sci. Eng. R, 2004, 44, p 45-89

X.-T. Luo, C.-X. Li, F.-L. Shang, G.-J. Yan, Y.-Y. Wang, and C.-J. Li, High Velocity Impact Induced Microstructure Evolution During Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254, p 11-20

G. Bae, J. Jang, and C. Lee, Correlation of Particle Impact Conditions with Bonding, Nanocrystal Formation and Mechanical Properties in Kinetic Sprayed Nickel, Acta Mater., 2012, 60, p 3524-3535

S. Yoon, H.J. Kim, and C. Lee, Deposition Behavior of Bulk Amorphous NiTiZrSiSn According to the Kinetic and Thermal Energy Levels in the Kinetic Spraying Process, Surf. Coat. Technol., 2006, 200, p 6022-6029

F. Gartner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15, p 223-232

D. Goldbaum, J.M. Shockley, R.R. Chromik, A. Rezaeian, S. Yue, E. Irissou, and J.G. Legoux, Document The Effect of Deposition Conditions on Adhesion Strength of Ti and Ti6Al4V Cold Spray Splats, J. Therm. Spray Technol., 2012, 21(2), p 288-303

X.K. Wu, J. Zhang, X. Zhou, H. Cui, and J. Liu, Advanced Cold Spray Technology: Deposition Characteristics and Potential Applications, Sci. China Technol. Sci., 2012, 55, p 357-368

J. Koike, D.M. Parkin, and M. Nastasi, Crystal-to-Amorphous Transformation of NiTi Induced by Cold Rolling, J. Mater. Res., 1990, 5, p 1414-1418

G.P. Dinda, H. Rosner, and G. Wilde, Cold-Rolling Induced Amorphization in Cu-Zr, Cu-Ti, Cu-Ti-Zr and Cu-Ti-Zr-Ni Multilayers, J. Non-Cryst. Solids, 2007, 353, p 3777-3781

Y. Xiong, K. Kang, G. Bae, S. Yoon, and C. Lee, Dynamic Amorphization and Recrystallization of Metals in Kinetic Spray Process, Appl. Phys. Lett., 2008, 92, p 194101-194113

H. Assadi, F. Gartner, T. Stolenhoff, H. Kreye, and K. Kang, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

H. Assadi, T. Schmidt, H. Richter, J.-O. Kliemann, K. Binder, F. Gärtner, T. Klassen, and H. Krey, On Parameter Selection in Cold Spraying, J. Therm. Spray. Technol., 2011, 20, p 1161-1176

J. Henao, A. Concustell, I.G. Cano, N. Cinca, S. Dosta, and J.M. Guilemany, Influence of Cold Gas Spray Process Conditions on the Microstructure of Fe-Based Amorphous Coatings, J. Alloy Compd., 2015, 622, p 995-999

A.L. Greer, Y.Q. Cheng, and E. Ma, Shear Bands in Metallic Glasses, Mater. Sci. Eng. R, 2013, 74(71), p 71-132

P. Cavaliere and A. Silvello, Processing Parameters Affecting Cold Spay Coatings Performances, Int. J. Adv. Manuf. Technol., 2014, 71, p 263-277

M. Villa, S. Dosta, J. Fernandez, and J.M. Guilemany, La proyección fría (CGs): Una alternativa a las tecnologías convencionales de deposición, Revista de Metalurgia, 2012, 48(3), p 175-191

T. Schmidt, F. Gartner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54, p 729-742

H. Tabbara, S. Gu, and D.G. McCartney, Computational Modelling of Titanium Particles in Warm Spray, Comput. Fluids, 2011, 44, p 358-368

W.Y. Li, H. Liao, C.-J. Li, G. Li, C. Coddet, and X.F. Wang, On High Velocity Impact of Micro-sized Metallic Particles in Cold Spraying, Appl. Surf. Sci., 2006, 253, p 2852-2862

Y. Zou, D. Goldbaum, J.A. Szpunar, and S. Yue, Microstructure and nanohardness of cold-sprayed coatings: Electron backscattered diffraction and nanoindentation studies, Scr. Mater., 2010, 62, p 395-398

D. Goldbaum, J.M. Shockley, R.R. Chromik, A. Rezaeian, S. Yue, J.G. Legoux, and E. Irissou, The Effect of Deposition Conditions on Adhesion Strength of Ti and Ti6Al4V Cold Spray Splats, J. Therm. Spray Technol., 2012, 21(2), p 288-303

P.H. Gao, C.-J. Li, G.J. Yang, Y.G. Li, and C.X. Li, Influence of Substrate Hardness on Deposition Behavior of Single Porous WC-12Co Particle in Cold Spraying, Surf. Coat. Technol., 2008, 203, p 384-390

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Thermal. Spray Technol., 1999, 8, p 559-564

J. Ajaja, D. Goldbaum, and R.R. Chromik, Characterization of Ti Cold Spray Coatings by Indentation Methods, Acta Astronaut., 2011, 69, p 923-928

D. Goldbaum, J. Ajaja, R.R. Chromika, W. Wong, S. Yue, E. Irissou, and J.G. Legoux, Mechanical Behavior of Ti Cold Spray Coatings Determined by a Multi-Scale Indentation Method, Mater. Sci. Eng. A, 2011, 530, p 253-265

H. Koivuluoto, A. Coleman, K. Murray, M. Kearns, and P. Vuoristo, High Pressure Cold Sprayed (HPCS) and Low Pressure Cold Sprayed (LPCS) Coatings Prepared from OFHC Cu Feedstock: Overview from Powder Characteristics to Coating Properties, J. Therm. Spray Technol., 2012, 21, p 1065-1075

L. Venkatesh, N.M. Chavan, and G. Sundararajan, The Influence of Powder Particle Velocity and Microstructure on the Properties of Cold Sprayed Copper Coatings, J. Therm. Spray Technol., 2011, 20, p 1009-1021

L. Ajdelsztajn, B. Jodoin, and J.M. Schoenung, Synthesis and Mechanical Properties of Nanocrystalline Ni Coatings Produced by Cold Gas Dynamic Spraying, Surf. Coat. Technol., 2006, 201, p 1166-1172

G. Bae, K. Kang, H. Na, J.-J. Kim, and C. Lee, Effect of Particle Size on the Microstructure and Properties of Kinetic Sprayed Nickel Coatings, Surf. Coat. Technol., 2010, 204, p 3326-3335

S. Yoon, C. Lee, H. Choi, H. Kim, and J. Bae, Impacting Behavior of Bulk Metallic Glass Powder at an Abnormally High Strain Rate During Kinetic Spraying, Mater. Sci. Eng. A, 2007, 449-451, p 911-915

X.-T. Luo, Y.-J. Li, C.-X. Li, G.-J. Yang, and C.-J. Li, Effect of Spray Conditions on Deposition Behavior and Microstructure of Cold Sprayed Ni Coatings Sprayed with a Porous Electrolytic Ni Powder, Surf. Coat. Technol., 2016, 289, p 85-93

C.-J. Li and W.Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167, p 278-283

C.-J. Li, G.J. Yang, P.H. Gao, J. Ma, Y.Y. Wang, and C.X. Li, Characterization of Nanostructured WC-Co Deposited by Cold Spraying, J. Therm. Spray Technol., 2007, 16, p 1011-1020

T. Suhonen, T. Varis, S. Dosta, M. Torrell, and J.M. Guilemany, Residual Stress Development in Cold Sprayed Al, Cu and Ti Coatings, Acta Mater., 2013, 61, p 6329-6337

W.B. Choi, L. Li, V. Luzin, R. Neiser, T.G. Herold, H.J. Prask, S. Sampath, and A. Gouldstone, Integrated Characterization of Cold Sprayed Aluminum Coatings, Acta Mater., 2007, 55, p 857-866

V. Luzin, K. Spencer, and M.X. Zhang, Residual Stress and Thermo-Mechanical Properties of Cold Spray Metal Coatings, Acta Mater., 2011, 59, p 1259-1270

C. Borchers, F. Gartner, T. Stoltenhoff, and H. Kreye, Formation of Persistent Dislocation Loops by Ultra-High Strain-Rate Deformation During Cold Spraying, Acta Mater., 2005, 53, p 2991-3000

E. Calla, D.G. McCartney, and P.H. Shipway, Effect of Deposition Conditions on the Properties and Annealing Behavior of Cold-Sprayed Copper, J. Therm. Spray Technol., 2006, 15, p 255-262

B.B. Straumal, A.A. Mazilkin, B. Baretzky, G. Schutz, E. Rabkin, and R.Z. Valiev, Accelerated Diffusion and Phase Transformations in Co-Cu Alloys Driven by the Severe Plastic Deformation, Mater. Trans., 2012, 53, p 63-71

A.A. Mazilkin, G.E. Abrosimova, S.G. Protasova, B.B. Straumal, G. Schutz, and S.V. Dobatkin, Transmission Electron Microscopy Investigation of Boundaries Between Amorphous Grains in Ni50Nb20Y30 Alloy, J. Mater. Sci., 2011, 46, p 4336-4342

K. Kang, H. Park, G. Bae, and C. Lee, Microstructure and Texture of Al Coating During Kinetic Spraying and Heat Treatment, J. Mater. Sci., 2012, 47(9), p 4053-4061

X.T. Luo, G.J. Yang, C.J. Li, and K. Kondoh, High Strain Rate Induced Localized Amorphization in Cubic BN/NiCrAl Nanocomposite Through High Velocity Impact, Scr. Mater., 2011, 65(7), p 581-584

G. Bae, K. Kang, and C. Lee, Nanoscale Deformation Twinning at Ultrahigh Strain Rates During Kinetic Spraying of Nickel, Mater. Lett., 2012, 89, p 320-323

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cavaliere, P., Perrone, A. & Silvello, A. Crystallization Evolution of Cold-Sprayed Pure Ni Coatings. J Therm Spray Tech 25, 1158–1167 (2016). https://doi.org/10.1007/s11666-016-0430-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0430-8