Abstract

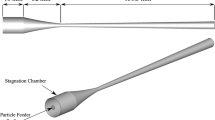

Cold spray is a solid-state rapid deposition technology in which metal powder is accelerated to supersonic speeds within a de Laval nozzle and then impacts onto the surface of a substrate. It is possible for cold spray to build thick structures, thus providing an opportunity for melt-less additive manufacturing. Image analysis of particle impact location and focused ion beam dissection of individual particles were utilized to validate a 3D multicomponent model of cold spray. Impact locations obtained using the 3D model were found to be in close agreement with the empirical data. Moreover, the 3D model revealed the particles’ velocity and temperature just before impact—parameters which are paramount for developing a full understanding of the deposition process. Further, it was found that the temperature and velocity variations in large-size particles before impact were far less than for the small-size particles. Therefore, an optimal particle temperature and velocity were identified, which gave the highest deformation after impact. The trajectory of the particles from the injection point to the moment of deposition in relation to propellant gas is visualized. This detailed information is expected to assist with the optimization of the deposition process, contributing to improved mechanical properties for additively manufactured cold spray titanium parts.

Similar content being viewed by others

References

S. Cadney, M. Brochu, P. Richer, and B. Jodoin, Cold Gas Dynamic Spraying as a Method for Freeforming and Joining Materials, Surf. Coatings Technol., 2008, 202(12), p 2801-2806

D. Kotoban, S. Grigoriev, A. Okunkova, and A. Sova, Influence of a Shape of Single Track on Deposition Efficiency of 316L Stainless Steel Powder in Cold Spray, Surf. Coatings Technol., 2016, 309, p 951-958

R.E. Blose, B.H. Walker, R.M. Walker, and S.H. Froes, New Opportunities to Use Cold Spray Process for Applying Additive Features to Titanium Alloys, Met. Powder Rep., 2006, 61(9), p 30-37

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkimov, and V. Fomin, Cold Spray Technology, 1st ed., A. Papyrin, Ed., Elsevier Ltd, New York, 2007

D. Riedlbauer, T. Scharowsky, R.F. Singer, P. Steinmann, C. Körner, and J. Mergheim, Macroscopic Simulation and Experimental Measurement of Melt Pool Characteristics in Selective Electron Beam Melting of Ti-6Al-4 V, Int. J. Adv. Manuf. Technol., 2016, 88, p 1-9

M. Faizan-Ur-Rab, S. H. Zahiri, S.H. Masood, M. Jahedi, and R. Nagarajah, 3D CFD Multicomponent Model for Cold Spray Additive Manufacturing of Titanium Particles, CFD Modeling and Simulation in Materials Processing 2016, John Wiley, Nashville, 2016, p 213-220.

M. Rab, S. Zahiri, S. Masood, M. Jahedi, and R. Nagarajah, Development of 3D Multicomponent Model for Cold Spray Process Using Nitrogen and Air, Coatings, 2015, 5(4), p 688-708

D. Goldbaum, R.R. Chromik, S. Yue, E. Irissou, and J.-G. Legoux, Mechanical Property Mapping of Cold Sprayed Ti Splats and Coatings, J. Therm. Spray Technol., 2011, 20(3), p 486-496

N.A. Buchmann, C. Atkinson, and J. Soria, Ultra-High-Speed Tomographic Digital Holographic Velocimetry in Supersonic Particle-Laden Jet Flows, Meas. Sci. Technol., 2013, 24, p 24005

S. Guetta, M.H. Berger, F. Borit, V. Guipont, M. Jeandin, and M. Boustie, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18(3), p 331-342

X.K. Suo, T.K. Liu, W.Y. Li, Q.L. Suo, M.P. Planche, and H.L. Liao, Numerical Study on the Effect of Nozzle Dimension on Particle Distribution in Cold Spraying, Surf. Coatings Technol., 2013, 220, p 107-111

S. Yin, Q. Liu, H. Liao, and X. Wang, Effect of Injection Pressure on Particle Acceleration, Dispersion and Deposition in Cold Spray, Comput. Mater. Sci., 2014, 90, p 7-15

B. Samareh and A. Dolatabadi, A Three-Dimensional Analysis of the Cold Spray Process: The Effects of Substrate Location and Shape, J. Therm. Spray Technol., 2007, 16(5-6), p 634-642

M. Faizan-Ur-Rab, S.H. Zahiri, S.H. Masood, T.D. Phan, M. Jahedi, and R. Nagarajah, Application of a Holistic 3D Model to Estimate State of Cold Spray Titanium Particles, Mater. Des., 2016, 89, p 1227-1241

M. Faizan-Ur-Rab, S.H. Zahiri, S.H. Masood, M. Jahedi, and R. Nagarajah, PIV Validation of 3D Multicomponent Model for Cold Spray Within Nitrogen and Helium Supersonic Flow Field, J. Therm. Spray Technol., 2017, 26(5), p 941-957

W.-Y. Li, C. Zhang, C.-J. Li, and H. Liao, Modeling Aspects of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, J. Therm. Spray Technol., 2009, 18(5-6), p 921-933

W.-Y. Li and W. Gao, Some Aspects on 3D Numerical Modeling of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, Appl. Surf. Sci., 2009, 255(18), p 7878-7892

W.-Y. Li, H. Liao, C.-J. Li, H.-S. Bang, and C. Coddet, Numerical Simulation of Deformation Behavior of Al Particles Impacting on Al Substrate and Effect of Surface Oxide Films on Interfacial Bonding in Cold Spraying, Appl. Surf. Sci., 2007, 253(11), p 5084-5091

P.C. King, C. Busch, T. Kittel-Sherri, M. Jahedi, and S. Gulizia, Interface Melding in Cold Spray Titanium Particle Impact, Surf. Coatings Technol., 2014, 239, p 191-199

H. Schlighting, Boundary Layer Theory, McGraw Hill, New York, 1979

B.E. Poling, J.M. Prausnitz, and J.P. O’Connell, The Properties of Gases and Liquids, McGraw Hill, New York, 2001

M. Karimi, A. Fartaj, G. Rankin, D. Vanderzwet, W. Birtch, and J. Villafuerte, Numerical Simulation of the Cold Gas Dynamic Spray Process, J. Therm. Spray Technol., 2006, 15(4), p 518-523

A. Kumar, S. Ghosh, and B.K. Dhindaw, Simulation of Cooling of Liquid Al–33wt.% Cu Droplet Impinging on a Metallic Substrate and Its Experimental Validation, Acta Mater., 2010, 58(1), p 122-133

S.H. Zahiri, T.D. Phan, S.H. Masood, and M. Jahedi, Development of Holistic Three-Dimensional Models for Cold Spray Supersonic Jet, J. Therm. Spray Technol., 2014, 23(6), p 919-933

D.K. Christoulis, S. Guetta, V. Guipont, and M. Jeandin, The Influence of the Substrate on the Deposition of Cold-Sprayed Titanium: An Experimental and Numerical Study, J. Therm. Spray Technol., 2011, 20(3), p 523-533

P.R. Spalart, Strategies for Turbulence Modelling and Simulations, Heat Fluid Flow, 2000, 21, p 252-263

H. Grotjans and F. Menter, Wall Functions for General Application {CFD} Codes., 1998

D.C. Wilcox, Turbulence Modeling for CFD, 3rd ed., DCW Industries, La Canada Flintridge p, 2000, p 91011

M. Karimi, G.W. Rankin, and B. Jodoin, Shock-Wave Induced Spraying: Gas and Particle Flow and Coating Analysis, Surf. Coatings Technol., 2012, 207, p 435-442

M. Meyer and R. Lupoi, An Analysis of the Particulate Flow in Cold Spray Nozzles, Mech. Sci, 2015, 6, p 127-136

D.-M. Chun, J.-O. Choi, C.S. Lee, and S.-H. Ahn, Effect of Stand-off Distance for Cold Gas Spraying of Fine Ceramic Particles, Surf. Coatings Technol., 2012, 206(8), p 2125-2132

R. Lupoi and W. O’Neill, Powder Stream Characteristics in Cold Spray Nozzles, Surf. Coat. Technol., 2011, 206, p 1069-1076

P.C. King and M. Jahedi, Relationship Between Particle Size and Deformation in the Cold Spray Process, Appl. Surf. Sci., 2010, 256(6), p 1735-1738

S.H. Zahiri, C.I. Antonio, and M. Jahedi, Elimination of Porosity in Directly Fabricated Titanium via Cold Gas Dynamic Spraying, J. Mater. Process. Technol., 2009, 209(2), p 922-929

P.C. King, S.H. Zahiri, and M. Jahedi, Focused Ion Beam Micro-Dissection of Cold-Sprayed Particles, Acta Mater., 2008, 56(19), p 5617-5626

W. Wong, P. Vo, E. Irissou, A.N. Ryabinin, J.-G. Legoux, and S. Yue, Effect of Particle Morphology and Size Distribution on Cold-Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2013, 22(7), p 1140-1153

T. Van Steenkiste, J. Smith, R. Teets, J. Moleski, D. Gorkiewicz, R. Tison, D. Marantz, K. Kowalsky, W. Riggs, P. Zajchowski, B. Pilsner, R. McCune, and K. Barnett, Kinetic Spray Coatings, Surf. Coatings Technol., 1999, 111, p 62-71

T. Van Steenkiste and J.R. Smith, Evaluation of Coatings Produced via Kinetic and Cold Spray Processes, J. Therm. Spray Technol., 2004, 13(2), p 274-282

T.H. Van Steenkiste, J.R. Smith, and R.E. Teets, Aluminum Coatings via Kinetic Spray with Relatively Large Powder Particles, Surf. Coatings Technol., 2002, 154, p 252-273

P. Cavaliere, A. Perrone, and A. Silvello, Mechanical and Microstructural Behavior of Nanocomposites Produced via Cold Spray, Compos. PART B, 2014, 67, p 326-331

P.C. King, S.H. Zahiri, and M. Jahedi, Microstructural Refinement within a Cold-Sprayed Copper Particle, Metall. Mater. Trans. A, 2009, 40(9), p 2115-2123

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process, J. Therm. Spray Technol., 1999, 8(4), p 576-582

H. Tabbara, S. Gu, D.G. McCartney, T.S. Price, and P.H. Shipway, Study on Process Optimization of Cold Gas Spraying, J. Therm. Spray Technol., 2011, 20(3), p 608-620

Acknowledgments

This experimental work was performed in part at the Melbourne Center for Nanofabrication.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faizan-Ur-Rab, M., Zahiri, S.H., King, P.C. et al. Utilization of Titanium Particle Impact Location to Validate a 3D Multicomponent Model for Cold Spray Additive Manufacturing. J Therm Spray Tech 26, 1874–1887 (2017). https://doi.org/10.1007/s11666-017-0628-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0628-4