Abstract

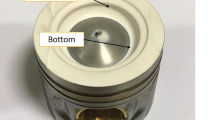

For the engines used in small turboprop aircrafts, the introduction of abradable coatings represents a feasible way to reach higher levels of overall engine efficiency, specifically by improving the fuel consumption and increasing the inter-turbine temperature margin. Abradable coatings on seals also contribute to improved hot restarts capability of an engine and lead to substantial extension of service life of the rotating counter bodies. In our contribution, we concentrate on flame-sprayed nickel-graphite abradable coating that can be used in turboprop engines both for seals and clearance control. The focus is the impact of spraying parameters on the physical and function properties of the abradable coating.

Similar content being viewed by others

References

Aircraft Propulsion System Performance Station Designation, SAE International Aerospace Standard. AS755 rev. F (2014).

R.E. Johnson, Mechanical Characterisation of AlSi-hBN, NiCrAl-Bentonite, and NiCrAl-Bentonite-hBN Free Standing Abradable Coatings, Surf. Coat. Technol., 2011, 205, p 3268-3273

Y. Maozahong, H. Baiyun, and H. Jiawen, Erosion Wear Behaviour and Model for Abradable Seal Coating, Wear, 2002, 252, p 9-15

X. Ma and A. Matthews, Evaluation of Abradable Seal Coating Mechanical Propeties, Wear, 2009, 267, p 1501-1510

Oerlicon Metco Material Product Data Sheet, Nickel Graphite Abradable Powders, DSMTS-0021.4—Nickel Graphite Abradable Powders © 2014 Oerlikon Metco

R. Soltani, M. Heydarzadeh-Soni, M. Ansari, F. Afsari, and Z. Valefui, Effect of APS Process Parameters on High-Temperature Wear Behavior of Nickel-Graphite Abradable Seal Coating, Surf. Coat. Technol., 2017, 321, p 403-408

J.J. Tang et al., The Influence of Size and Distrubution of Graphite on the Frictional and Wear Behaviour of Ni-Graphite Coatings, Surf. Coat. Technol., 2014, 252, p 48-55

H.I. Faraoun et al., Imrovement of Thermally, Sprayed Abradable Coating by Microstructure Control, Surf. Coat. Technol., 2006, 201, p 2303-2312

B. Bartlett, Optimization of 75% nickel – 25% Graphite Spray Parameters to Meet Coating Application Design Criteria, White Paper by Oerlikon Metco (2014)

S.H. Leght and C.C. Berndt, Evaluation of Off-Angle Therma Spray, Surf. Coat. Technol., 1997, 89(3), p 213-224

Š. Houdková, M. Kašparová, and F. Zahálka, The Influence of Spraying Angle on Properties of HVOF Sprayed Hardmetal Coatings, J. Therm. Spray Technol., 2010, 19(5), p 893-901

H.M. Rietveld, A Profile Refinement Method for Nuclear and Magnetic Structures, J. Appl. Crystallogr., 1969, 2, p 65-71

Y. Maozhong, H. Baiyun, and H. Jiawen, Erosion Wear Behaviour and Model of Abradable Seal Coating, Wear, 2002, 252(1-2), p 9-15

Acknowledgments

The paper has originated in the framework of the solution of the Ministry of Trade of the Czech Republic project number FV-TRIO FV10211. The authors would like to thank F. Lukáč from IPP ASCR for providing the XRD analyses and M. Bystrianský from RTI UWB for SEM analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ziegelheim, J., Lombardi, L., Cesanek, Z. et al. Abradable Coatings for Small Turboprop Engines: A Case Study of Nickel-Graphite Coating. J Therm Spray Tech 28, 794–802 (2019). https://doi.org/10.1007/s11666-019-00838-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00838-4