Abstract

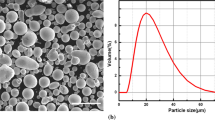

This research aims at understanding the spray coating of NiCrBSi with different amount of tungsten carbide particles on JIS SUP9 steel substrate. The amount of tungsten carbide added to NiCrBSi was 0, 20, and 40% by volume to reinforce the coating. Microstructures, microhardness, adhesion, cohesion, and rigidity of coating were characterized. The results revealed that NiCrBSi structure composed of nickel solid solution as matrix embedded with Ni boride and Ni4Si with chromium carbide distributed across the coating. Tungsten carbide particles were apparent in the coating and they partially diffused into the NiCrBSi coating. In the case of 40% tungsten carbide addition, the matrix hardness was increased by 29.18%, but the cohesion of coating was reduced by 22.94%. The adhesion failure was not apparent in all samples examined in this study under the 20 N scratch load. Wear area of coatings mixed with tungsten carbide addition was found to decrease by 3.5 to 8.8 times compared to the substrate. As per the findings, the addition of WC can promote the wear resistance by its reinforcement and also introduce the solid solution strengthening of W in the NiCrBSi matrix, specifically in the Ni solid solution.

Similar content being viewed by others

References

M.A. Garrido, A. Rico, M.T. Gómez, M. Cadenas, J.E. Fernández-Rico, and J. Rodríguez, Tribological and Oxidative Behavior of Thermally Sprayed NiCrBSi Coatings, J. Therm. Spray Technol., 2017, 26, p 517-529

K. Bobzin, M. Öte, T.F. Linke, and K.M. Malik, Wear and Corrosion Resistance of Fe-Based Coatings Reinforced by TiC Particles for Application in Hydraulic Systems, J. Therm. Spray Technol., 2016, 25, p 365-374

R. González, M. Cadenas, R. Fernández, J.L. Cortizo, and E. Rodríguez, Wear Behaviour of Flame Sprayed NiCrBSi Coating Remelted by Flame or by Laser, Wear, 2007, 262, p 301-307

J.R. Davis, Handbook of Thermal Spray Technology, ASM International, Almere, 2004

J.R. Davis, ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys, ASM International, Almere, 2000

C. Navas, R. Colaço, J. de Damborenea, and R. Vilar, Abrasive Wear Behaviour of Laser Clad and Flame Sprayed-Melted NiCrBSi Coatings, Surf. Coat. Technol., 2006, 200, p 6854-6862

K. Gurumoorthy, M. Kamaraj, K.P. Rao, A.S. Rao, and S. Venugopal, Microstructural Aspects of Plasma Transferred Arc Surfaced Ni-Based Hardfacing Alloy, Mater. Sci. Eng. A, 2007, 456, p 11-19

S. Dong, B. Song, H. Liao, and C. Coddet, Deposition of NiCrBSi Coatings by Atmospheric Plasma Spraying and Dry-Ice Blasting: Microstructure and Wear Resistance, Surf. Coat. Technol., 2015, 268, p 36-45

A. Vencl, S. Arostegui, G. Favaro, F. Zivic, M. Mrdak, S. Mitrovic, and V. Popovic, Evaluation of Adhesion/Cohesion Bond Strength of the thick Plasma Spray Coatings by Scratch Testing on Coatings Cross-Sections, Tribol. Int., 2011, 44, p 1281-1288

P. Niranatlumpong and H. Koiprasert, Phase Transformation of NiCrBSi–WC and NiBSi–WC Arc Sprayed Coatings, Surf. Coat. Technol., 2011, 206, p 440-445

H. Yu, W. Zhang, H. Wang, Y. Guo, M. Wei, Z. Song, and Y. Wang, Bonding and Sliding Wear Behaviors of the Plasma Sprayed NiCrBSi Coatings, Tribol. Int., 2013, 66, p 105-113

P. Reinaldo and A.S. D’Oliveira, NiCrSiB Coatings Deposited by Plasma Transferred Arc on Different Steel Substrates, J. Mater. Eng. Perform., 2011, 22, p 590-597

S.W. Huang, M. Samandi, and M. Brandt, Abrasive Wear Performance and Microstructure of Laser Clad WC/Ni Layers, Wear, 2004, 256, p 1095-1105

M.R. Fernández, A. García, J.M. Cuetos, R. González, A. Noriega, and M. Cadenas, Effect of Actual WC Content on the Reciprocating Wear of a Laser Cladding NiCrBSi Alloy Reinforced with WC, Wear, 2015, 324–325, p 80-89

K. Van Acker, D. Vanhoyweghen, R. Persoons, and J. Vangrunderbeek, Influence of Tungsten Carbide Particle Size and Distribution on the Wear Resistance of Laser Clad WC/Ni Coatings, Wear, 2005, 258, p 194-202

M.J. Tobar, C. Álvarez, J.M. Amado, G. Rodríguez, and A. Yáñez, Morphology and Characterization of Laser Clad Composite NiCrBSi–WC Coatings on Stainless Steel, Surf. Coat. Technol., 2006, 200, p 6313-6317

P.F. Mendez, N. Barnes, K. Bell, S.D. Borle, S.S. Gajapathi, S.D. Guest, H. Izadi, A.K. Gol, and G. Wood, Welding Processes for Wear Resistant Overlays, J. Manuf. Process., 2014, 16, p 4-25

D. Deschuyteneer, F. Petit, M. Gonon, and F. Cambier, Processing and Characterization of Laser Clad NiCrBSi/WC Composite Coatings—Influence of Microstructure on Hardness and Wear, Surf. Coat. Technol., 2015, 283, p 162-171

Acknowledgments

This work is a part of “Application of Thermal Spray in Agricultural Part” project, supported by Innovation and Technology Assistance Program (iTAP) under National Science and Technology Development Agency (NSTDA) and Acme International (Thailand) Ltd. The authors would like to express their gratitude and gratefully acknowledge.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Usana-ampaipong, T., Dumkum, C., Tuchinda, K. et al. Surface and Subsurface Characteristics of NiCrBSi Coating with Different WC Amount Prepared by Flame Spray Method. J Therm Spray Tech 28, 580–590 (2019). https://doi.org/10.1007/s11666-019-00839-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00839-3