Abstract

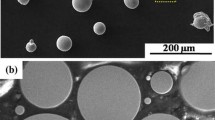

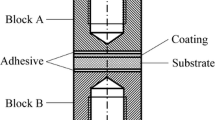

NiTi shape-memory alloy coatings were deposited by atmospheric plasma spray (APS) on mild-steel substrates and their mechanical properties such as hardness (Vickers’s microhardness), adhesion strength (ASTM C-633), and wear resistance (solid particle erosion) analyzed. The physical characteristics of the surface and interface of the as-deposited coating were investigated using scanning electron microscopy (SEM), energy-dispersive spectroscopy (EDS), and x-ray diffraction (XRD) analysis. Also, the as-deposited coatings were exposed to airborne particle erosion to investigate their wear behavior for different erodent impact angles. The correlations between various plasma parameters and the erosive wear resistance and mechanical properties of the coating were established. In addition, the surface morphology of the eroded surface was investigated by scanning electron microscopy to analyze the different wear mechanisms (plastic deformation, crater formation, splat boundary pile-up, and lip formation) occurring on the surface.

Similar content being viewed by others

References

G.P. Tilly, Erosion Caused by Impact of Solid Particles, Treatise on Materials Science and Technology, Academic Press Inc., 2013, https://doi.org/10.1016/s0161-9160(13)70071-1

R. Westergård, L.C. Erickson, N. Axén, H.M. Hawthorne, and S. Hogmark, The Erosion and Abrasion Characteristics of Alumina Coatings Plasma Sprayed under Different Spraying Conditions, Tribol. Int., 1998, 31(5), p 271-279

D. Toma, W. Brandl, and G. Marginean, Wear and Corrosion Behaviour of Thermally Sprayed Cermet Coatings, Surf. Coatings Technol., 2001, 138(2-3), p 149-158

Y. Fu, A.W. Batchelor, Y. Wang, and K.A. Khor, Fretting Wear Behaviors of Thermal Sprayed Hydroxyapatite (HA) Coating under Unlubricated Conditions, Wear, 1998, 217(1), p 132-139

H. Liao, B. Normand, and C. Coddet, Influence of Coating Microstructure on the Abrasive Wear Resistance of WC/Co Cermet Coatings, Surf. Coatings Technol., 2000, 124(2-3), p 235-242

H. Herman and H. Herman, Plasma-Sprayed Coatings, Sci. Am., 1988, 259(3), p 112-117

S. Lathabai, M. Ottmüller, and I. Fernandez, Solid Particle Erosion Behaviour of Thermal Sprayed Ceramic, Metallic and Polymer Coatings, Wear, 1998, 221(2), p 93-108

H. Hiraga, T. Inoue, H. Shimura, and A. Matsunawa, Cavitation Erosion Mechanism of NiTi Coatings Made by Laser Plasma Hybrid Spraying, Wear, 1999, 231(2), p 272-278

J. Stella, E. Schüller, C. Heßing, O.A. Hamed, M. Pohl, and D. Stöver, Cavitation Erosion of Plasma-Sprayed NiTi Coatings, Wear, 2006, 260(9-10), p 1020-1027

M. Bram, A. Ahmad-Khanlou, H.P. Buchkremer, and D. Stöver, Vacuum Plasma Spraying of NiTi Protection Layers, Mater. Lett., 2002, 57(3), p 647-651

M.M. Verdian, K. Raeissi, and M. Salehi, Corrosion Performance of HVOF and APS Thermally Sprayed NiTi Intermetallic Coatings in 3.5% NaCl Solution, Corros. Sci., Elsevier Ltd, 2010, 52(3), p 1052-1059, https://doi.org/10.1016/j.corsci.2009.11.034.

M.M. Verdian, K. Raeissi, and M. Salehi, Electrochemical Impedance Spectroscopy of HVOF-Sprayed NiTi Intermetallic Coatings Deposited on AISI 1045 Steel, J. Alloys Compd., Elsevier B.V., 2010, 507(1), p 42-46, https://doi.org/10.1016/j.jallcom.2010.07.132.

J.M. Guilemany, N. Cinca, S. Dosta, and A. V. Benedetti, Corrosion Behaviour of Thermal Sprayed Nitinol Coatings, Corros. Sci., Elsevier Ltd, 2009, 51(1), p 171-180, https://doi.org/10.1016/j.corsci.2008.10.022.

M. Bitzer, N. Rauhut, G. Mauer, M. Bram, R. Vaßen, H.P. Buchkremer, D. Stöver, and M. Pohl, Cavitation-Resistant NiTi Coatings Produced by Low-Pressure Plasma Spraying (LPPS), Wear, Elsevier, 2015, 328-329, p 369-377. https://doi.org/10.1016/j.wear.2015.03.003

Z. Shi, J. Wang, Z. Wang, Y. Qiao, T. Xiong, and Y. Zheng, Cavitation Erosion and Jet Impingement Erosion Behavior of the NiTi Coating Produced by Air Plasma Spraying, Coatings, 2018, 8(10).

B. Swain, S. Bajpai, and A. Behera, Microstructural Evolution of NITINOL and Their Species Formed by Atmospheric Plasma Spraying, Surf. Topogr. Metrol. Prop., IOP Publishing, 2018, 7(1), p 015006, https://doi.org/10.1088/2051-672x/aaf30e.

V.K. Singh, S. Bambroo, S. Sinha, U.K. Mahto, and R. Keshavamurthy, Corrosion Behaviour of Plasma Sprayed Flyash Coatings on Mild Steel Substrate, Int. J. Appl. Eng. Res., 2015, 10(55), p 3911-3914

K. Otsuka and X. Ren, Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys, Prog. Mater. Sci., 2005, 50(5), p 511-678

“Nickel Titanium - Wikipedia,” n.d., https://en.wikipedia.org/wiki/Nickel_titanium. Accessed 2 December 2019.

R.H. Richman, A.S. Rao, and D.E. Hodgson, Cavitation Erosion of Two NiTi Alloys, Wear, 1992, 157(2), p 401-407

X. Zhang and H. Sehitoglu, Crystallography of the B2 → R → B19′ Phase Transformations in NiTi, Mater. Sci. Eng. A, 2004, 374(1-2), p 292-302

M.F. Morks and A. Kobayashi, Influence of Spray Parameters on the Microstructure and Mechanical Properties of Gas-Tunnel Plasma Sprayed Hydroxyapatite Coatings, Mater. Sci. Eng. B Solid-State Mater. Adv. Technol., 2007, 139(2-3), p 209-215.

C.K. Lin and C.C. Berndt, Measurement and Analysis of Adhesion Strength for Thermally Sprayed Coatings * Measurement and Analysis of Adhesion Strength for Thermally Sprayed Coatings, J. Therm. Spray Technol., 1994, 3(March), p 75-104

A. Satapathy, “Thermal Spray Coating of Red Mud on Metals,” 2005.

Y. Morisada, H. Fujii, T. Mizuno, G. Abe, T. Nagaoka, and M. Fukusumi, Modification of Thermally Sprayed Cemented Carbide Layer by Friction Stir Processing, Surf. Coatings Technol., Elsevier B.V., 2010, 204(15), p 2459-2464, https://doi.org/10.1016/j.surfcoat.2010.01.021.

C.R. Deo, “Preparation and Characterization of Polymer Matrix Composite Using Natural Fiber Lantana-Camara Polymer Matrix Composite Using,” 2010.

B.R. Lawn and D.B. Marshall, Hardness, Toughness, and Brittleness: An Indentation Analysis, J. Am. Ceram. Soc., 1979, 62(7-8), p 347-350

A.S.M. Ang and C.C. Berndt, A Review of Testing Methods for Thermal Spray Coatings, Int. Mater. Rev., 2014, 59(4), p 179-223

Y. Maozhong, H. Baiyun, and H. Jiawen, Erosion Wear Behaviour and Model for Abradable Seal Coating, Wear, 2002, 252(1-2), p 9-15

B. Swain, A. Patnaik, S.K. Bhuyan, K.N. Barik, S.K. Sethi, S. Samal, S.C. Mishra, and A. Behera, “Solid Particle Erosion Wear on Plasma Sprayed Mild Steel and Copper Surface,” Materials Today: Proceedings, 2018.

C.S. Ramesh, R. Keshavamurthy, B.H. Channabasappa, and S. Pramod, Influence of Heat Treatment on Slurry Erosive Wear Resistance of Al6061 Alloy, Mater. Des., Elsevier Ltd, 2009, 30(9), p 3713-3722, https://doi.org/10.1016/j.matdes.2009.02.009.

N.M. Barkoula, J. Gremmels, and J. Karger-Kocsis, Dependence of Solid Particle Erosion on the Cross-Link Density in an Epoxy Resin Modified by Hygrothermally Decomposed Polyurethane, Wear, 2001, 247(1), p 100-108

R. Arji, D.K. Dwivedi, and S.R. Gupta, Sand Slurry Erosive Wear of Thermal Sprayed Coating of Stellite, Surf. Eng., 2007, 23(5), p 391-397

G. Grant and W. Tabakoff, Erosion Prediction in Turbomachinery Resulting from Environmental Solid Particles, J. Aircr., 1975, 12(5), p 471-478. https://doi.org/10.2514/3.59826

H.H. Tian and G.R. Addie, Experimental Study on Erosive Wear of Some Metallic Materials Using Coriolis Wear Testing Approach, Wear, 2005, 258(1-4 SPEC. ISS.), p 458-469.

I. Finnie, Erosion of Surfaces by Solid Particles, Wear, 1960, 3(2), p 87-103

D.K. Goyal, H. Singh, H. Kumar, and V. Sahni, Erosive Wear Study of HVOF Spray Cr 3 C 2 -NiCr Coated CA6NM Turbine Steel, J. Tribol., 2014, 136(4), p 041602, https://doi.org/10.1115/1.4027621.

S.B. Mishra, S. Prakash, and K. Chandra, Studies on Erosion Behaviour of Plasma Sprayed Coatings on a Ni-Based Superalloy, Wear, 2006, 260(4-5), p 422-432

D. Aquaro and E. Fontani, Erosion of Ductile and Brittle Materials, Meccanica, 2002, 36(6), p 651-661

H. Imrek, M. Bagci, and O.M. Khalfan, Solid Particle Erosion as Influenced by Tensile Axial Loads, Tribol. Trans., 2011, 54(5), p 779-783. https://doi.org/10.1080/10402004.2011.603459

Acknowledgements

The authors would like to thank Hindustan Aeronautics Limited (HAL), Koraput Division for doing the atmospheric plasma spray coating in the Thermal Spray Division and also the National Institute of Technology, Rourkela for carrying out all the characterizations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Swain, B., Mallick, P., Bhuyan, S.K. et al. Mechanical Properties of NiTi Plasma Spray Coating. J Therm Spray Tech 29, 741–755 (2020). https://doi.org/10.1007/s11666-020-01017-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01017-6