Abstract

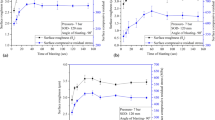

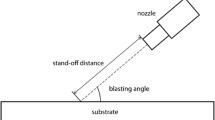

This paper examines how the grit blasting process influences the surface roughness of different sub-strates, the grit residue, and the grit erosion. The influence of grit blasting conditions on induced sub-strate residual stresses is also discussed. Aluminum alloy, cast iron, and hard steel were blasted with white alumina grits of 0.5,1, and 1.4 mm mean diameters. Grit blasting was performed using either a suction-type or a pressure-type machine equipped with straight nozzles made of B4C. The influence of the follow-ing parameters was studied: grit blasting distance (56 to 200 mm), blasting time (3 to 30 s), angle between nozzle and blasted surface (30°, 60°, 90°), and blasting pressure (0.2 to 0.7 MPa). The roughness of the substrate was characterized either by using a perthometer or by image analysis. The grit residue remain-ing at the blasted surface was evaluated after cleaning by image analysis. The residual stresses induced by grit blasting were determined by using the incremental hole drilling method and by measuring the de-flection of grit-blasted beams.

Grit size was determined to be the most important influence on roughness. The average values of Ra and Rt and the percentage of grit residue increased with grit size as well as the depth of the plastic zone under the substrate. An increase of the pressure slightly increased the values of Äa and Rt but also promoted grit breakdown and grit residue.

A blasting time of 3 to 6 s was sufficient to obtain the highest roughness and limit the grit breakdown. The residual stresses generated under the blasted surface were compressive, and the depth of the affected zone depended on the grit diameter, the blasting pressure, and the Young’s modulus of the substrate. More-over, the maximum residual stress was reached at the limit of the plastic zone (i.e., several tenths of a mil-limeter below the substrate surface).

Similar content being viewed by others

References

Thermal Spraying, American Welding Society, 1985

J.M. Zaat, Thermal Spraying, Ann. Rev. Mater. Sci., Vol 13,1983, p 9- 42

S. Kitahara and A. Hasui, A Study of the Bonding Mechanism of Sprayed Coatings, J. Vac. Sci. Technol., Vol 11 (No. 4), 1974, p 747–753

C.P. Bergmann, Preheating of Substrate as Adherence Agent of Plasma Sprayed Coatings, Thermal Spraying ’93, D. Von Hofe and E. Lugsheider, Ed., DVS, Düsseldorf, 1993, p 114–118

W. Funk, F. Coebe, and M. Manz, The Influence of Substrate Temperature on the Bond Strength of Plasma Sprayed Oxide Ceramics, 1st Plasma-Technik Symp., Vol 1, H. Eschnauer, P. Huber, A.R. Nicoll, and S. Sandmeier, Ed., P.T. Wohlen, 1988, p 59–66

M. Mellali, P. Fauchais, and A. Grimaud, Influence of Substrate Rough- ness and Temperature on Alumina Coatings Adhesion-Cohesion, Surf. Coat. Technol., Vol 81 (No. 2–3), 1996, p 275–286

J. Wiggren, Grit Blasting as Surface Preparation before Plasma Spraying, Thermal Spray: Advances in Coating Technology, D. Houck, Ed., ASM International, 1988, p 99

C. Beauvais, Surface Preparation, Introduction, Surface Treatment, J. Techniques de l’Ingénieur, Metallurgie-M5,1982, p 1435

J. J. Dupras and G. Gamier, Chemical Decreasing, Surface Treatment, J. Techniques de l’Ingénieur, Metallurgie-M5,1982, p 1450

R.L. Apps, The Significance of Surface Preparation and Flame Spray- ing of Metals, Chem. Eng., Vol 292,1974, p 769–773

D.M. Karpinos, V.G. Zil’Bergerg, A.M. Vyal’Tsev, and V.S. Kud, Shot Blasting as Means of Preparing Surfaces for Plasma Deposition, Powder Metall. Mater. Parts Coat., 1979, p 675–678

S. Amada, H. Yamada, S. Yematsu, and Y. Saotome, Modelling and Measurements of Adhesive Strength of Thermal Spray Coatings, Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 915–920

S. Amada and Y. Yamada, Introduction of Fractal Dimension to Adhesive Strength of Plasma Sprayed Coatings, 11th Int. Symp. Plasma Chemistry, Vol 1, J. Harry, Ed., Loughborough, U.K., 1993, p 150–155

D.H. James, AReview of Experimental Findings in Surface Preparation for Thermal Spraying, J. Mech. Work. Technol, Vol 10, 1984, p 221- 232

S.J. Yankee, R.L. Salsbury, and B.J. Pletka, Quality Control of Hydroxylapatite Coatings: The Surface Preparation Stage, Thermal Spray Coatings: Properties, Processes and Applications, T.T. Bernecki, Ed., ASM International, 1991, p 475–481

M. Mellali, “Influence of Roughness and Temperature of Substrates on Adhesion/Cohesion and Residual Stresses of Plasma Sprayed Alumina Coatings,” Ph.D. thesis, University of Limoges, France, 18 July 1994

C. Richard, “Study of Mechanical Characteristics of Thermal Spray Coatings,” Ph.D. thesis, University of Technology of Compiègne, France, 18 Dec 1992

J. Lu, A. Niku-Lari, and J.F. Flavenot, Measurement of the Through Thickness Stress Distribution by the Incremental Hole Drilling Method, Mèm. Etud. Sci. Rev. Mètall., 1985, p 69–81

D.J. Greving, V.R. Shadleg, and E.F. Rybicki, Effects of Coatings Thickness and Residual Stresses on Bond Strength of C633-79 Thermal Spray Coating Test Specimens, Thermal Spray Industrial Applications, C.C. Berndt and S. Sampath, Ed., ASM International, 1994, p 639–645

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mellali, M., Grimaud, A., Leger, A.C. et al. Alumina grit blasting parameters for surface preparation in the plasma spraying operation. J Therm Spray Tech 6, 217–227 (1997). https://doi.org/10.1007/s11666-997-0016-6

Issue Date:

DOI: https://doi.org/10.1007/s11666-997-0016-6