Abstract

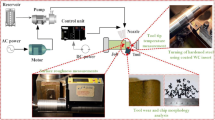

In this current research, mist cooling and dry cutting effects on cutting force, flank wear, chip morphology, crater wear, surface roughness and microhardness of chip have been evaluated during hard turning operation of EN-24 grade steel having hardness of 48 HRC. Water-soluble oil was applied for cooling and lubricating purposes in mist cooling, and a comprehensive comparative analysis was performed with dry machining environment. Dry machining was found more effective as compared to mist cooling technique against the chip microhardness and cutting force. For other responses like crater wear, flank wear, surface roughness and chip morphology, the cooling setup having coolant delivered in mist form performed better than dry machining owing to reduction in cutting zone temperature and complimentary modification in chip–tool interaction during hard turning.

Similar content being viewed by others

References

N.V.V.S. Sudheer et al., Investigation on influence of refrigerated air and high heat transfer rate MQL in turning of aluminium metal matrix composite, in 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati, Assam, India 12th–14th December 2014, pp. 454-1–454-6

S.A. Lawal et al., Experimental evaluation and optimization of flank wear during turning of AISI 4340 steel with coated carbide inserts using different cutting fluids. J. Inst. Eng. India Ser. C 96(1), 21–28 (2015)

L.E.A. Sanchez et al., Cleaner machining through a tool holder with internal cooling, in 3rd International workshop Advances in Cleaner Production Sao Paulo-Brazil, 18th–20th May 2011, pp. 1–10

A.U. Alkali et al., Influence of Cutting conditions on chip formation when turning ASSAB DF-3 hardened tool steel. Int. J. Mater. Mech. Manuf. 1(1), 76–79 (2013)

A. Saini et al., Experimental estimation and optimization of process parameters under minimum quantity lubrication and dry turning of AISI- 4340 with different carbide inserts. J. Mech. Sci. Technol. 28(6), 2307–2318 (2014)

A. Vardhaman et al., Examining the role of cutting fluids in machining AISI 1040 steel using Taungsten carbide insert under minimal quantity lubrication condition, in 3rd International Conference on Advances in Engineering Sciences & Applied Mathematics (ICAESAM 2015) 23–24th March 2015, pp. 80–83

M.H.S. Elmunafi et al., Tool life of coated carbide cutting tool when turning hardened stainless steel under minimum quantity lubricant using castor oil, in 2nd International Materials, Industrial, and Manufacturing Engineering Conference, MIMEC2015, Bali Indonesia, Procedia Manufacturing, 4–6th February 2015, pp. 563–567

D.A. Stephenson et al., Rough turning Inconel 750 with supercritical CO2-based minimum quantity lubrication. J. Mater. Process. Technol. 214(3), 673–680 (2014)

P.S.C. Bose et al., Role of MQL and nano fluids on the machining of NICROFER C263, in 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati Assam, India, 12th–14th December 2014, pp. 363-1–363-5

P.V. Krishna et al., Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel. Int. J. Mach. Tools Manuf. 50(10), 911–916 (2010)

P. Netake, S. Chinchanikar, Hard turning under minimum quantity lubrication: modelling of cutting force and surface roughness. J. Adv. Eng. Res. 2(1), 17–22 (2015)

G.S. Goindi et al., Investigation of ionic liquids as metal working fluids in minimum quantity lubrication machining of AISI 1045 Steel, in 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), IIT Guwahati Assam, India, 12th–14th December 2014, pp. 277-1–277-6

D.K. Sharma, U.S. Dixit, A comparison of dry and air-cooled turning of grey cast iron with mixed oxide ceramic tool. J. Mater. Process. Technol. 190(1–3), 160–172 (2007)

M.M.A. Khan et al., Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Process. Technol. 209(15–16), 5573–5583 (2009)

S.J. Ojolo et al., Experimental determination of the effects of some straight biological oils on cutting force during cylindrical turning. Rev. Mater. 13(4), 650–663 (2008)

N.R. Dhar et al., The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J. Mater. Process. Technol. 171(1), 93–99 (2006)

A.E. Diniz et al., Influence of refrigeration/lubrication condition on SAE 52100 hardened steel turning at several cutting speeds. Int. J. Mach. Tools Manuf. 43(3), 317–326 (2003)

S.S. Gill et al., Wear behaviour of cryogenically treated tungsten carbide inserts under dry and wet turning conditions. Int. J. Mach. Tools Manuf. 49(3–4), 256–260 (2009)

A. Attanasio et al., Minimal quantity lubrication in turning: effect on tool wear. Wear 260(3), 333–338 (2006)

O. Cakir et al., Comparison of gases applications to wet and dry cutting in turning. J. Mater. Process. Technol. 153–154, 35–41 (2004)

P. Selopal, O.S. Bhatia, Lubrication: a review. Int. J. Adv. Res. Ideas Innov. Technol. 1(2), 1–7 (2015)

G. Singh et al., Experimental investigations of vegetable & mineral oil performance during machining of En-31 steel with minimum quantity lubrication. Int. J. Res. Eng. Technol. 2(6), 1030–1037 (2013)

R.W. Maruda et al., Tool wear characterizations in finish turning of AISI 1045 carbon steel for MQCL conditions. Wear 372–373, 54–67 (2017)

R.W. Maruda et al., The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism. J. Manuf. Process. 24, 107–115 (2016)

R.W. Maruda, E. Feldshtein, Some features of ecological finish turning of low carbon steels. Achiev. Mech. Technol. Autom. 33(2), 13–23 (2013)

R.W. Maruda et al., Effect of anti-wear additive on cutting tool and surface layer of workpiece state under MQCL conditions. Tech. Gaz. 22(5), 1219–1223 (2015)

R.W. Maruda et al., Influence of cooling conditions on the machining process under MQCL and MQL conditions. Tech. Gaz. 22(4), 965–970 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, A., Tirkey, N., Patel, S.K. et al. A Comparison of Machinability in Hard Turning of EN-24 Alloy Steel Under Mist Cooled and Dry Cutting Environments with a Coated Cermet Tool. J Fail. Anal. and Preven. 19, 115–130 (2019). https://doi.org/10.1007/s11668-018-0574-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0574-6