Abstract

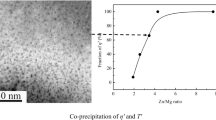

The effects of Zn and Mg variations on the precipitated phases and the properties of Al-Zn-Mg-Cu alloys are investigated in this study. The quantities of stable and metastable phases have been calculated under various Zn and Mg contents by using software package JmatPro. The results show that the amount of the main hardening η (MgZn2) phase and η′ phase increase with higher Zn and Mg contents. T (AlCuMgZn) phase and metastable counterpart significantly increase with the reduction of Zn contents or the increase of Mg contents. S (Al2CuMg) phase reduces gradually with the increase of Mg content, while S phase varies only slightly with the Zn content. The precipitation of GP zones is promoted by the increase of Zn or Mg content. The physical and mechanical properties of the alloys have been modelled in such way that increasing Zn or Mg content could reduce electrical conductivity and thermal conductivity, while the mechanical properties improve with increasing Zn content and varies markedly as Mg content changes from 2.7 to 2.9 wt.%.

Similar content being viewed by others

References

P. Sepehrband and S. Esmaeili, Application of Recently Developed Approaches to Microstructural Characterization and Yield Strength Modeling of Aluminum Alloy AA7030, Mater. Sci. Eng. A, 2008, 487, p 309-315

X.M. Li and M.J. Starink, The Effect of Compositional Variations on Characteristics of Coarse Intermetallic Particles in Overaged 7000 Aluminium Alloys, Mater. Sci. Technol., 2001, 171, p 324-1328

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux, Evolution of Precipitate Microstructures During the Retrogression and Re-Ageing Heat Treatment of an Al-Zn-Mg-Cu Alloy, Acta Mater., 2010, 58, p 248-260

M.J. Starink and X.M. Li, A Model for the Electrical Conductivity of Peak Aged and Overaged Al-Zn-Mg-Cu Alloys, Metall. Mater. Trans. A, 2003, 34A, p 899-911

J.K. Park and A.J. Ardell, Precipitate. Microstructure of Peak-Aged 7075 Al, Scripta Metall., 1988, 22, p 1115-1119

N. Yazdian, F. Karimzadeh, and M. Tavoosi, Microstructural Evolution of Nanostructure 7075 Aluminum Alloy During Isothermal Annealing, J. Alloys Compd., 2010, 493, p 137-141

K. Osamura, K. Kohno, and H. Okuda, Mesoscopic Structure of Super-High Strength P/M Al-Zn-Mg-Cu Alloys, Mater. Sci. Forum, 1996, 217-222, p 1829-1834

J. Polmear, Light Alloys—Metallurgy of the Light Metals, St. Edmundsbury Press Ltd, Suffolk, 1995

Z. Guo, N. Saunders, A.P. Miodownik, and J.-Ph. Schille, Modelling of Materials Properties and Behaviour Critical to Casting Simulation, Mater. Sci. Eng. A, 2005, 413-414, p 465-469

N. Saunders, Z. Guo, X. Li, A.P. Miodownik, and J.-Ph. Schillé, Using JMatPro to Model Materials Properties and Behavior, JOM, 2003, 55, p 60-65

Z. Guo, N. Saunders, J.P. Schillé, and A.P. Miodownik, Material Properties for Process Simulation, Mater. Sci. Eng. A, 2009, 499, p 7-13

M. Založnik and B. Sarler, Modeling of Macrosegregation in Direct-Chill Casting of Aluminum Alloys: Estimating the Influence of Casting Parameters, Mater. Sci. Eng. A, 2005, 413-414, p 5-91

X. Li, A.P. Miodownik, and N. Saunders, Modelling of Materials Properties in Duplex Stainless Steels, Mater. Sci. Technol., 2002, 18, p 861-868

N. Saunders, Z. Guo, X. Li, A.P. Miodownik, and J.P. Schillé, Modelling the Material Properties and Behaviour of Ni-Based Superalloys, Superalloys 2004, K.A. Green, T.M. Pollock, H. Harada, T.E. Howson, R.C. Reed, J.J. Schirra, and S. Walston, Ed., The Minerals, Metals & Materials Society (TMS), 2004, p 849-858

N. Saunders, Phase Diagram Calculations for Ni-Based Superalloys, Superalloys 1996, R.D. Kissinger, Ed., TMS, Warrendale, 1996,

X. Cao, N. Saunders, and J. Campbell, Effect of Iron and Manganese Contents on Convection-Free Precipitation and Sedimentation of Primary α-Al(FeMn)Si Phase in Liquid Al-11.5Si-0.4Mg Alloy, J. Mater. Sci., 2004, 39, p 2303-2314

A. Sullivan and J.D. Robson, Microstructural Properties of Friction Stir Welded and Post-Weld Heat-Treated 7449 Aluminium Alloy Thick Plate, Mater. Sci. Eng. A, 2008, 478, p 351-360

N. Kamp, A. Sullivan, and J.D. Robson, Modelling of Friction Stir Welding of 7xxx Aluminium Alloys, Mater. Sci. Eng. A, 2007, 466, p 246-255

Z. Guo and W. Sha, Quantification of Precipitate Fraction in Al-Si-Cu Alloys, Mater. Sci. Eng. A, 2005, 392, p 449-452

N. Saunders and A.P. Miodownik, CALPHAD—Calculation of Phase Diagrams: A Comprehensive Guide, Pergamon Materials Series, Vol 1, R.W. Cahn, Ed., Elsevier, Oxford, 1998,

H.M. Flower, High Performance Materials in Aerospace, Chapman & Hall, London, 1995

H.R. Shercliff and M.F. Ashby, A Process Model for Age Hardening of Aluminium Alloys-I. The Model, Acta Metall. Mater., 1990, 38, p 1789-1802

A. Deschamps, F. Livet, and Y. Brechet, Influence of Predeformation on Ageing in an Al-Zn-Mg alloy. I. Microstructure Evolution and Mechanical Properties, Acta Mater., 1998, 47, p 281-292

S.P. Alpay and R. Gurbuz, The Effect of Coarse Second Phase Particles on Fatigue Crack Propagation of An Al-Zn-Mg-Cu Alloy, Scripta Metall., 1994, 30, p 1373-1376

J.D. Robson and P.B. Prangnell, Dispersoid Precipitation and Process Modelling in Zirconium Containing Commercial Aluminium Alloys, Acta Mater., 2001, 49, p 599-613

M. Dhiman, D.K. Dwivedi, R. Sehgal, and I.K. Bhat, Effect of Iron on Microstructure of Al-12Si-1Cu-0.1Mg Alloy, Mater. Manuf. Process., 2008, 23, p 805-808

D.J. Strawbridge, W. Hume-Rothery, and A.T. Little, The Constitution of Al-Cu-Mg-Zn Alloys at 460 °C, J. Inst. Met., 1948, 74, p 191-225

H. Loffler, I. Kavaks, and J. Lendvai, Decomposition Processes in Al-Zn-Mg Alloys, J. Mater. Sci., 1983, 18, p 2215-2240

T. Ungár, The Formation of Guinier-Preston Zones in the Al-4.8 wt.%Zn-1.2 wt.%Mg Alloy Studied by X-Ray Small Angle Scattering, Z. Metallkd., 1979, 40, p 739-747

G. Groma, E. Kovács-Csetényi, I. Kovács, J. Lendvai, and T. Ungár, The Composition of Guinier-Preston Zones in Al-Zn-Mg Alloys, Philos. Mag. A, 1979, 70, p 653-665

K.S. Ghosh, K. Das, and U.K. Chatterjee, Correlation of Stress Corrosion Cracking Behaviour with Electrical Conductivity and Open Circuit Potential in Al-Li-Cu-Mg-Zr Alloys, Mater. Corros., 2007, 58, p 181-188

T.C. Tsai and T.H. Chuang, Relationship Between Electrical Conductivity and Stress Corrosion Cracking Susceptibility of Al 7075 and Al 7475 Alloys, Corrosion, 1996, 6, p 414-416

J. Guo and M.T. Samonds, Alloy Thermal Physical Property Prediction Coupled Computational Thermodynamics with Back Diffusion Consideration, J. Phase Equilib. Diffus., 2007, 28, p 58-63

J.K. Park and A.J. Ardell, Relationship Between Electrical Conductivity, Stress Corrosion Cracking Susceptibility of Al 7075 and Al 7475 Alloys, Acta Metall. Mater., 1991, 39, p 591-598

P. Olafsson, R. Sandstrom, and A. Karlsson, Electrical Conductivity of Aluminium Alloys, Mater. Sci. Forum, 1996, 217-222, p 981-986

Y. Zeng, S. Mul, P. Wu, K.P. Ong, and J. Zhang, Relative Effects of All Chemical Elements on the Electrical Conductivity of Metal and Alloys: An Alternative to Norbury-Linde Rule, J. Alloys Compd., 2009, 478, p 345-354

J.M. Molina, R. Prieto, J. Narcisoa, and E. Louis, The Effect of Porosity on the Thermal Conductivity of Al-12 wt.% Si/SiC Composites, Scripta Mater., 2009, 60, p 582-585

L.F. Mondolfo, Aluminium Alloys: Structure and Properties, Butterworth & Co Ltd, London, 1976

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, J., Li, X. Modelling of the Precipitated Phases and Properties of Al-Zn-Mg-Cu Alloys. J. Phase Equilib. Diffus. 32, 350–360 (2011). https://doi.org/10.1007/s11669-011-9911-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-011-9911-0