Abstract

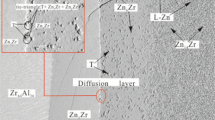

The phase diagram of the Al-Er-Zr ternary system at 773 K has been experimentally investigated by means of x-ray powder diffraction (XRD), differential thermal analysis (DTA) and scanning electron microscopy (SEM) with energy dispersive analysis (EDX). The existence of 13 binary compounds, i.e. Al3Zr, Al2Zr, Al3Zr2, AlZr, Al3Zr4, Al2Zr3, AlZr2, AlZr3, Al3Er, Al2Er, AlEr, Al2Er3 and AlEr2 was confirmed. It is proved that the phases Al3Zr5 and Al4Zr5 do not exist at 773 K. The isothermal section consists of 16 single-phase regions, 29 binary-phase regions and 14 ternary-phase regions. The maximum solid solubility of Zr in Al3Er, Al2Er, AlEr, Al2Er3 and Er is about 9, 14, 4.5, 5.4, and 12 at.% Zr, respectively. No remarkable solid solubility could be found in the other compounds of this ternary system at 773 K. No ternary compound is found in the present work.

Similar content being viewed by others

References

X.D. Du, Study on Ageing and Creep of Al-0.1Zr Alloy, Mater. Sci. Eng. A, 2006, 432, p 84-89

B. Forbord, R.H. Mathiesen, J. Mårdalen, T. Furu, and H.I. Lange, Thermal Stability of Al3(Sc x ,Zr1−x )-Dispersoids in Extruded Aluminium Alloys, Mater. Sci. Eng., 2008, 479A, p 313-323

S. Kaneko, K. Murakami, and T. Sakai, Effect of the Extrusion Conditions on Microstructure Evolution of the Extruded Al-Mg-Si-Cu Alloy Rods, Mater. Sci. Eng., 2009, 500A, p 8-15

Z. Yin, Q. Pan, Y. Zhang, and F. Jiang, Effect of Minor Sc and Zr on the Microstructure and Mechanical Properties of Al-Mg Based Alloys, Mater. Sci. Eng., 2000, 280A, p 151-155

B. Forbord, W. Lefebvre, F. Danoix, H. Hallem, and K. Marthinsen, Three Dimensional Atom Probe Investigation on the Formation of Al3(Sc,Zr)-Dispersoids in Aluminium Alloys, Scripta Mater., 2004, 51, p 333-337

M.S. Chuang and G.C. Tu, The Effect of Nb-Addition on the L12 Precipitates of Rapidly-Solidified Al-Cr-Zr Alloy, Scripta Metall. Mater., 1995, 33, p 1999-2005

W.-S. Lee, T.-H. Chen, C.-F. Lin, and M.-S. Chen, Impact Deformation Behaviour and Dislocation Substructure of Al-Sc Alloy, J. Alloys Compd., 2010, 493, p 580-589

S. Bai, Z. Liu, Y. Li, Y. Hou, and X. Chen, Microstructures and Fatigue Fracture Behavior of an Al-Cu-Mg-Ag Alloy with Addition of Rare Earth Er, Mater. Sci. Eng. A, 2010, 527, p 1806-1814

S.H. Liu, Y. Du, and H.L. Chen, A Thermodynamic Reassessment of the Al-Y System, CALPHAD, 2006, 30, p 334-340

C. Watanabe, R. Monzen, and K. Tazaki, Effects of Al3Sc Particle Size and Precipitate-Free Zones on Fatigue Behavior and Dislocation Structure of an Aged Al-Mg-Sc Alloy, J. Fatigue, 2008, 30, p 635-641

W. Lefebvre, F. Danoix, H. Hallem, B. Forbord, A. Bostel, and K. Marthinsen, Precipitation Kinetic of Al3(Sc,Zr) Dispersoids in Aluminium, J. Alloys Compd., 2009, 470, p 107-110

S. Lathabai and P.G. Lloyd, The Effect of Scandium on the Microstructure, Mechanical Properties and Weldability of a Cast Al-Mg Alloy, Acta Mater., 2002, 50, p 4275-4292

R.A. Karnesky, D.C. Dunand, and D.N. Seidman, Evolution of Nanoscale Precipitates in Al Microalloyed with Sc and Er, Acta Mater., 2009, 57, p 4022-4031

S.P. Wen, Z.B. Xing, H. Huang, B.L. Li, W. Wang, and Z.R. Nie, The Effect of Erbium on the Microstructure and Mechanical Properties of Al-Mg-Mn-Zr Alloy, Mater. Sci. Eng. A, 2009, 516, p 42-49

K.A. Gschneidner, Jr., and F.W. Calderwood, Al-Er System, Bull. Alloy Phase Diagr., 1988, 9(6), p 713-714

H. Okamoto, Zr-Al Phase Diagram, J. Phase Equilib., 2002, 23, p 455-456

B. Predel, Er-Zr (Erbium-Zirconium), O. Madelung, Ed., SpringerMaterials—The Landolt-Börnstein Database. doi:10.1007/10474837_1243

P. Villars, Pearson’s Handbook of Crystallographic Data, ASM International, Materials Park, OH, 1997, p 488-489

P. Villars, Pearson’s Handbook of Crystallographic Data, ASM International, Materials Park, OH, 1997, p 364-365

S. Lin, Z. Nie, H. Huang, C. ZHAN, Z. Xing, and W. Wang, Thermodynamic Calculation of Er-X and Al-Er-X Compounds Existing in Al-Mg-Mn-Zr-Er Alloy, Trans. Nonferr. Met. Soc. China, 2010, 20, p 682-687

Materials Data JADE Release 5, XRD Pattern Processing, Materials Data Inc., Livermore, CA, 2002

J. She, Y. Zhan, Z. Hu, C. Li, J. Hu, Y. Du, and H. Xu, Experimental Study of Al-Zr-Y System Phase Equilibria at 773 K, J. Alloys Compd., 2010, 497, p 118-120

J. She, Y. Zhan, C. Li, Y. Du, H. Xu, and Y. He, Phase Equilibria of the Al-Pr-Zr Ternary System at 773 K, J. Alloys Compd., 2010, 503, p 57-60

Z. Hu, Y. Zhan, J. She, Y. Du, and H. Xu, Phase Equilibria in the Al-Zr-Ce System at 773 K, J. Alloys Compd., 2010, 491, p 200-202

M. Pang, Y. Zhan, W. Yang, C. Li, and Y. Du, The Phase Relationships in the Al-Zr-Ho Ternary System at 773 K, J. Alloys Compd., 2010, 508, p 79-84

Z. Yang, Y. Zhan, H. Mo, Y. Du, and H. Xu, Determination of the Phase Equilibria in the Al-Er-V Ternary System at 773 K, J. Alloys Compd., 2010, 503, p 61-64

L.G. Zhang, L.B. Liu, G.X. Huang, H.Y. Qi, B.R. Jia, and Z.P. Jin, Thermodynamic Assessment of the Al-Cu-Er System, CALPHAD, 2008, 32, p 527-534

Y. Zhan, Y. Du, and Y. Zhuang, Determination of Phase Diagrams Using Equilibrated Alloys, Methods for Phase Diagram Determination, 1st ed., J.-C. Zhao, Ed., Elsevier Science Press, Amsterdam, 2007, p 108-150

Acknowledgments

This work is supported by the National Natural Science Foundation of China (50831007), the Guangxi Science and Technology Development Project (1114003-1, 2011GXNSFA018017) and the Plans for Construction of Scientific Topnotch and Innovation Team in Guangxi University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, J., Zhan, Y., Pang, M. et al. Experimental Phase Diagram of the Al-Er-Zr Ternary System. J. Phase Equilib. Diffus. 32, 412–417 (2011). https://doi.org/10.1007/s11669-011-9929-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-011-9929-3