Abstract

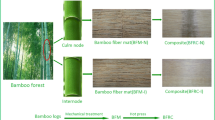

Bamboo is a unique fiber-reinforced bio-composite with fibers embedded into a parenchyma cell matrix. We conducted axial compression tests on bamboo blocks prepared from bottom to top, and from inner to outer portions of the culm. The apparent Young’s modulus and compressive strength of whole thickness bamboo blocks exhibited slight increases with increasing height along the culm, due to slight increases of fiber volume fraction (Vf) from 28.4 to 30.4%. Other blocks showed a significant increase in apparent Young’s modulus and strength from the inner to outer part of the culm wall, mainly owing to a sharp increase of Vf from 17.1 to 59.8%. With a decrease of fiber fraction volume there was a transition from relatively brittle behavior to very ductile behavior in bamboo blocks. Results indicated that stiffness and strength of bamboo was primarily due to fiber in compression, and ductility of bamboo was provided by the parenchyma cell matrix acting as a natural fiber-reinforced composite.

Similar content being viewed by others

References

Ahmad M, Kamke FA (2005) Analysis of calcutta bamboo for structural composite materials: physical and mechanical properties. Wood Sci Technol 39(6):448–459

Amada S, Ichikawa Y, Munekata T, Nagase Y, Shimizu H (1997) Fiber texture and mechanical graded structure of bamboo. Compos Part B Eng 28(1):13–20

Baets J, Wouters K, Hendrickx K, Vuure AWV (2015) Compressive properties of natural fibre composites. Mater Lett 149:138–140

Chung KF, Yu WK (2002) Mechanical properties of structural bamboo for bamboo scaffoldings. Eng Struct 24(4):429–442

Dixon PG, Gibson LJ (2014) The structure and mechanics of moso bamboo material. J R Soc Interface 11(99):20140321

Ghavami K, Rodrigues CS, Paciornik S (2003) Bamboo: functionally graded composite material. Asian J Civ Eng 4(4):1–10

Habibi MK, Samaei AT, Gheshlaghi B, Jian L, Yang L (2015) Asymmetric flexural behavior from bamboo’s functionally graded hierarchical structure: underlying mechanisms. Acta Biomater 16:178–186

Huang DS, Zhou AP, Li HT, Su Y, Chen G (2012) Experimental study on the tensile properties of bamboo related to its distribution of vascular bundles. Key Eng Mater 517:112–117

Huang P, Chang WS, Ansell MP, Chew YMJ, Shea A (2015) Density distribution profile for internodes and nodes of phyllostachys edulis (moso bamboo) by computer tomography scanning. Constr Build Mater 93:197–204

Krause JQ, Silva FDA, Ghavami K, Gomes ODFM, Filho RDT (2016) On the influence of dendrocalamus giganteus, bamboo microstructure on its mechanical behavior. Constr Build Mater 127:199–209

Li HT, Zhang QS, Huang DS, Deekz AJ (2013) Compressive performance of laminated bamboo. Compos Part B Eng 54(1):319–328

Liu H, Wang X, Zhang X, Sun Z, Jiang Z (2016) In situ detection of the fracture behaviour of moso bamboo (phyllostachys pubescens) by scanning electron microscopy. Holzforschung 70:1–8

Lo TY, Cui HZ, Leung HC (2004) The effect of fiber density on strength capacity of bamboo. Mater Lett 58(21):2595–2598

Lo TY, Cui HZ, Tang PWC, Leung HC (2008) Strength analysis of bamboo by microscopic investigation of bamboo fibre. Constr Build Mater 22(7):1532–1535

Nogata F, Takahashi H (1995) Intelligent functionally graded material: bamboo. Compos Eng 5(7):743–751

Obataya E, Kitin P, Yamauchi H (2007) Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber foam composite structure. Wood Sci Technol 41:385–400

Qi J, Xie J, Yu W, Chen S (2015) Effects of characteristic inhomogeneity of bamboo culm nodes on mechanical properties of bamboo fiber reinforced composite. J Forestry Res 26(4):1–4

Ray AK, Mondal S, Das SK, Ramachandrarao P (2005) Bamboo—a functionally graded composite-correlation between microstructure and mechanical strength. J Mater Sci 40(19):5249–5253

Shang L, Sun Z, Liu X, Jiang Z (2015) A novel method for measuring mechanical properties of vascular bundles in moso bamboo. J Wood Sci 61(6):562–568

Shao ZP, Fang CH, Tian GL (2009) Mode I interlaminar fracture property of moso bamboo (phyllostachys pubescens). Wood Sci Technol 43(5):527–536

Shao ZP, Fang CH, Huang SX (2010) Tensile properties of moso bamboo (phyllostachys pubescens) and its components with respect to its fiber-reinforced composite structure. Wood Sci Technol 44(4):655–666

Silva ECN, Walters MC, Paulino GH (2006) Modeling bamboo as a functionally graded material: lessons for the analysis of affordable materials. J Mater Sci 41(21):6991–7004

Tan T, Rahbar N, Allameh SM, Kwofie S, Dissmore D, Ghavami K, Soboyejo WO (2011) Mechanical properties of functionally graded hierarchical bamboo structures. Acta Biomater 7(10):3796–3803

Verma CS, Chariar VM (2013) Stiffness and strength analysis of four layered laminate bamboo composite at macroscopic scale. Compos Part B Eng 45(1):369–376

Verma CS, Sharma NK, Chariar VM, Maheshwari S, Hada MK (2014) Comparative study of mechanical properties of bamboo laminae and their laminates with woods and wood based composites. Compos Part B Eng 60(2):523–530

Wang X, Ren H, Zhang B, Fei B, Burgert I (2012) Cell wall structure and formation of maturing fibres of moso bamboo (phyllostachys pubescens) increase buckling resistance. J R Soc Interface 9(70):988–996

Wang H, Li W, Ren D, Yu Z, Yu Y (2014) A two-variable model for predicting the effects of moisture content and density on compressive strength parallel to the grain for moso bamboo. J Wood Sci 60(5):362–366

Wegst UG (2011) Bending efficiency through property gradients in bamboo, palm, and wood-based composites. J Mechl Behav Biomed 4(5):744–755

Xiao Y, Li L, Yang R, Shan B, She L (2013) Experimental study on creep and loading property of laminated bamboo bridge. Build Struc 43(18):86–91

Xu Q, Harries K, Li X, Liu Q, Gottron J (2014) Mechanical properties of structural bamboo following immersion in water. Eng Struct 81:230–239

Zhang X, Li J, Yu Z, Yu Y, Wang H (2017) Compressive failure mechanism and buckling analysis of the graded hierarchical bamboo structure. J Mater Sci 52(12):6999–7007

Acknowledgements

We are grateful to the Basic Scientific Research Funds of International Center for Bamboo and Rattan (1632016007) and the National Science Foundation of China (31400519) for their financial support for this research.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Project funding

This study is supported by Basic Scientific Research Funds of International Center for Bamboo and Rattan (1632016007) and the National Science Foundation of China (31400519).

The online version is available at http://www.springerlink.com

Corresponding editor: Zhu Hong.

Rights and permissions

About this article

Cite this article

Zhang, X., Yu, Z., Yu, Y. et al. Axial compressive behavior of Moso Bamboo and its components with respect to fiber-reinforced composite structure. J. For. Res. 30, 2371–2377 (2019). https://doi.org/10.1007/s11676-018-0780-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11676-018-0780-9