Abstract

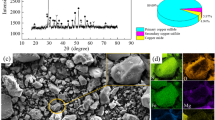

Sulfuric acid leaching process was applied to extract nickel from roasting-dissolving residue of a spent catalyst, the effect of different parameters on nickel extraction was investigated by leaching experiments, and the leaching kinetics of nickel was analyzed. The experimental results indicate that the effects of particle size and sulfuric acid concentration on the nickel extraction are remarkable; the effect of reaction temperature is mild; while the effect of stirring speed in the range of 400–1 200 r/min is negligible. Decreasing particle size or increasing sulfuric acid concentration and reaction temperature, the nickel extraction efficiency is improved. 93.5% of nickel in residue is extracted under suitable leaching conditions, including particle size (0.074–0.100) mm, sulfuric acid concentration 30% (mass fraction), temperature 80 °C, reaction time 180 min, mass ratio of liquid to solid 10 and stirring speed 800 r/min. The leaching kinetics analyses shows that the reaction rate of leaching process is controlled by diffusion through the product layer, and the calculated activation energy of 15.8 kJ/mol is characteristic for a diffusion controlled process.

Similar content being viewed by others

References

JIANG Yuan, HOU Meng-xi. The study of global nickel supply and demand [J]. Non-ferrous Mining and Metallurgy, 2008, 24(2): 55–57. (in Chinese)

HANSON D J. Nickel [J]. Chemical and Engineering News, 2003, 81(36): 82.

MARAFI M, STANISLAUS A. Spent hydroprocessing catalyst management: A review. Part II. Advances in metal recovery and safe disposal methods [J]. Resources, Conservation and Recycling, 2008, 53(1/2): 1–26.

VALVERDE J I M, PAULINO J F, AFONSO J C. Hydrometallurgical route to recover molybdenum, nickel, cobalt and aluminum from spent hydrotreating catalysts in sulphuric acid medium [J]. Journal of Hazardous Materials, 2008, 160(2/3): 310–317.

GHANEM R, FARAG H, ELTAWEEL Y, OSSMAN M E. Recovery of nickel from spent catalyst by single- and multi-stage leaching process [J]. International Journal of Environment and Waste Management, 2008, 2(6): 540–548.

CARLA L, PASQUALI M. Electrolytic nickel recovery from lithium-ion batteries [J]. Minerals Engineering, 2003, 16(6): 537–542.

LUPI C, PASQUALI M, DELL’ERA A. Nickel and cobalt recycling from lithium-ion batteries by electrochemical processes [J]. Waste Management, 2005, 25(2): 215–220.

TZANETAKIS N, SCOTT K. Recycling of nickel-metal hydride batteries. II: Electrochemical deposition of cobalt and nickel [J]. Journal of Chemical Technology and Biotechnology, 2004, 79(9): 927–934.

ZHUANG J M, WALSH T, HOBENSHIELD E. Nickel recovery and stabilization of nickel waste tailings [J]. International Journal of Mining, Reclamation and Environment, 2006, 20(2): 127–141.

AL-MANSI N M, ABDEL MONEM N M. Recovery of nickel oxide from spent catalyst [J]. Waste Management, 2002, 22(1): 85–90.

SAHU K K, AQARWAL A, PANDEY B D. Nickel recovery from spent nickel catalyst [J]. Waste Management and Research, 2005, 23(2): 148–154.

CHEN Yun, FENG Qi-ming, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Study on the recycling of valuable metals in spent Al2O3-based catalyst [J]. Minerals and Metallurgical Processing, 2007, 24(1): 30–34.

CHAUDHARY A J, DONALDSON J D, BODDINGTON S C, GRIMES S M. Heavy metals in the environment. Part II: A hydrochloric acid leaching process for the recovery of nickel value from a spent catalyst [J]. Hydrometallurgy, 1993, 34(2): 137–150.

MA Cheng-bin, WANG Shu-fang, YUAN Ying-bin. Study on the recovery of spent catalysts containing molybdenum, nickel, bismuth and cobalt [J]. China Molybdenum Industry, 2007, 31(5): 23–25. (in Chinese)

LAI Y D, LIU J C. Leaching behaviors of Ni and V from spent catalyst [J]. Journal of Hazardous Materials, 1997, 53(2): 213–224.

BOSIO V, VIERA M, DONATI E. Integrated bacterial process for the treatment of a spent nickel catalyst [J]. Journal of Hazardous Materials, 2008, 154(1/3): 804–810.

MULAK W, MIAZGA B, SZYMCZYCHA A. Kinetics of nickel leaching from spent catalyst in sulphuric acid solution [J]. International Journal of Mineral Processing, 2005, 77(4): 231–235.

ABDEL-AAL E A, RASHAD M M. Kinetic study on the leaching of spent nickel oxide catalyst with sulfuric acid [J]. Hydrometallurgy, 2004, 74(3): 189–194.

FENG Qi-ming, CHEN Yun, SHAO Yan-hai, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. New technique of comprehensive utilization of spent Al2O3-based catalyst [J]. Journal of Central South University of Technology, 2006, 13(2): 151–155.

SOUZA A D, PINA P S, LIMA E V O, DA SILVA C A, LEÃO V A. Kinetics of sulphuric acid leaching of a zinc silicate calcine[J]. Hydrometallurgy, 2007, 89(3/4): 337–345.

DENG C H, FENG Q M, CHEN Y. Studies on the leaching kinetics of cobalt from spent catalyst with sulphuric acid [J]. Mineral Processing and Extractive Metallurgy, 2007, 116(3): 159–162.

ZHU Bing-chen. Chemical reaction engineering [M]. Beijing: Chemical Industry Press, 1993: 353–357. (in Chinese)

ABDEL-AAL E A. Kinetics of sulfuric acid leaching of low-grade zinc silicate ore [J]. Hydrometallurgy, 2000, 55(3): 247–254.

ANAND S, DAS S C, DAS R P, JENA P K. Leaching of manganese nodules at elevated temperature and pressure in the presence of oxygen [J]. Hydrometallurgy, 1988, 20(2): 155–167.

LOZANO L J, JUAN D. Leaching of vanadium from spent sulphuric acid catalysts [J]. Minerals Engineering, 2001, 14(5): 543–546.

LUO L, WEI J H, WU G Y, TOYOHISA F, ATSUSHI S. Extraction studies of cobalt (II) and nickel (II) from chloride solution using PC88A [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 687–692.

TSAKIRIDIS P E, AGATZINI S L. Process for the recovery of cobalt and nickel in the presence of magnesium and calcium from sulphate solutions by Versatic 10 and Cyanex 272[J]. Minerals Engineering, 2004, 17(4): 535–543.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project (50574101) supported by the National Natural Science Foundation of China; Project (2003UDBEA00C020) supported by the Collaborative Project of School and Province of Yunnan Province, China

Rights and permissions

About this article

Cite this article

Feng, Qm., Shao, Yh., Ou, Lm. et al. Kinetics of nickel leaching from roasting-dissolving residue of spent catalyst with sulfuric acid. J. Cent. South Univ. Technol. 16, 410–415 (2009). https://doi.org/10.1007/s11771-009-0069-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0069-4