Abstract

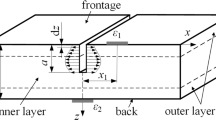

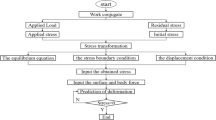

Residual stress distributions in 7075 aluminum alloy thick plates with different thicknesses and different quenching speeds were measured. A shape function of stress distribution was proposed based on the internal stress distribution characteristics of aluminum alloy. Using nonlinear regression technology, the function between stress value of key points on internal stress curve and surface stress of the plate was obtained. Based on the measured surface stress, stress value of key points and stress distribution shape, the internal stress distribution can be reconstructed. The experiments show that the model is of good engineering practicality.

Similar content being viewed by others

References

MICHAEL B P, MICHAEL R H. Residual stress, stress relief, and inhomogeneity in aluminum plate [J]. Scripta Materialia, 2002, 46(1): 77–82.

MUAMMER K, JOHN C, TAYLAN A. Prediction of residual stresses in quenched aluminium blocks and their reduction through cold working processes [J]. Journal of Materials Processing Technology, 2006, 174(1/2/3): 342–354.

ZHAO Li-li, ZHANG Yi-du. FEM simulation for residual stress in quenched aeronautics aluminium alloy thick-plate based on rolled residual stresses distribution [J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(1): 88–91. (in Chinese)

ZHAO Zu-de, WANG Qiu-cheng, KANG Feng, WANG Jian-guo. Numerical simulation of three-dimensional residual-stress field in 7A04 aluminum cone-shaped part after the quench-cooling process [J]. Journal of Zhejiang University of Technology, 2007, 35(3): 304–307. (in Chinese)

YAO Can-yang. Numerical simulation of quench temperature field and internal stress field of aluminum alloy 7050 thick plate [D]. Changsha: Central South University, 2007. (in Chinese)

KE Ying-ling, DONG Hui-yue. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick-plates [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 639–645. (in Chinese)

VAIDYNATHAN S, IAIN F. Determination of residual stresses from stress intensity factor measurements [J]. Journal of Basic Engineering, 1971, 93(4): 242–246.

GONG Hai, WU Yun-xin, LIAO Kai. Influence of pre-stretching on residual stress distribution in 7075 aluminum alloy thick-plate [J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 201–205. (in Chinese)

LIAO Kai, WU Yun-xin, GONG Hai, ZHANG Shu-yuan. Application of integral method on residual stress calculation along depth in aluminium alloy thick plate [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1006–1011. (in Chinese)

WEILI C, IAIN F. Residual stress measurement and the slitting method [M]. New York: Springer, 2006: 70–82.

MICHAEL B P. Experimental procedure for crack compliance measurements of residual stress [EB/OL]. https://doi.org/www.lanl.gov/residual/. 2002.

MICHAEL B P. Residual stress measurement by successive extension of a slot: the crack compliance [J]. Applied Mechanics Review, 1999, 52(2): 75–96.

MICHAEL B P, THOMAS G H. Residual stress measurements in a thick, dissimilar aluminium alloy friction stir weld [J]. Acta Materialia, 2006, 54(15): 4013–4021.

MICHAEL B P, MICHAE H R. Uncertainty analysis, model error, and order selection for series-expanded, residual-stress inverse solutions [J]. Journal of Engineering Materials and Technology, 2006, 128(2): 175–185.

MICHAEL B P, PIERLUIGI P. Uncertainty, model error, and improving the accuracy of residual stress inverse solutions [C]// Proceedings of the 2006 SEM Annual Conference and Exposition on Experimental and Applied Mechanics. Los Alamos: 2006: 176–187.

HE Shao-hua, WEN Zhu-qing, LOU Tao. Experiment design and data processing [M]. Changsha: National University of Defence Technology Press, 2002: 144–185. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(2005CB623708, 2010CB731703) supported by the National Basic Research Program of China

Rights and permissions

About this article

Cite this article

Gong, H., Wu, Yx. & Liao, K. Prediction model of residual stress field in aluminum alloy plate. J. Cent. South Univ. Technol. 18, 285–289 (2011). https://doi.org/10.1007/s11771-011-0692-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-011-0692-8