Abstract

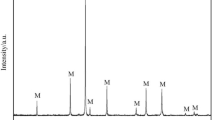

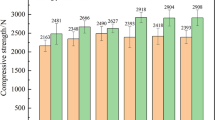

The mechanism of high pressure roll grinding on improvement of compression strength of oxidized hematite pellets was researched by considering their roasting properties. The results indicate that oxidized hematite pellets require higher preheating temperature and longer preheating time to attain required compression strength of pellets compared with the common magnetite oxidized pellets. It is found that when the hematite concentrates are pretreated by high pressure roll grinding (HPRG), the compression strengths of preheated and roasted oxidized hematite pellets get improved even with lower preheating and roasting temperatures and shorter preheating and roasting time. The mechanism for HPRG to improve roasting properties of oxidized pellets were investigated and the cause mainly lies in the increase of micro-sized particles and the decrease of dispersion degree for hematite concentrates, which promotes the hematite concentrate particles to be compacted, the solid-phase crystallization, and finally the formation of Fe2O3 bonding bridges during subsequent high temperature roasting process.

Similar content being viewed by others

References

WILLS B A, NAPIER-MUM T J. Wills’ mineral processing technology [M]. Changsha: Central South University Press and Elsevier Ltd, 2008: 134–137.

ABDEL-ZAHER M A, DOUGLS W F. Grinding of mineral mixtures in high-pressure grinding rolls [J]. Int J Miner Process, 2009, 93: 59–65.

FUERSTENAU D W, ABOUZEID A Z M. Role of feed moisture in high-pressure roll mill comminution [J]. Int J Miner Process, 2007, 82: 203–204.

FUERSTENAU D W, SHUKL A, KAPUR P C. Energy consumption and product size distribution in choke-fed, high-compression roll mills [J]. Int J Miner Process, 1991, 32: 59–79.

TAVARES L M. Particle weakening in high-pressure roll grinding [J]. Minerals Engineering, 2005, 18: 651–657.

LIM I L, VOIGT W, WELLER K R. Particles size distributionand energy expenditure in grinding minerals and ores in high-pressureroll mills [J]. Int J Miner Process, 1996, 44: 539–541.

FUERSTENAUA D W, DEB A, KAPURE P C. Linear and nonlinear particle breakage processes in comminution systems [J]. Miner Process, 2004, 745: 317–327.

LIU Shu, WANG Yong-qing. The application of HPRG (RP3.6-120/50B) at Chengchao pellet plant [J]. Pellet Technology, 2006(1): 38–39. (in Chinese)

ZHANG Yan-bin, Grinding test of iron ore concentrates by high pressure roll mill [J]. Sintering and Pelletizing, 2005, 30(3): 14–16. (in Chinese)

WANG Chang-an, XIONG Shou-an, ZHU De-qin. Effect of high pressure roller mill pre-treatment concentrates on green ball property [J]. Sintering and Pelletizing, 2002, 27(6): 12–15. (in Chinese)

QIU Guan-zhou, ZHU De-qin, PAN Jian, WANG Chang-an, GUO Yu-feng, JIANG Tao, HU Chen-fan, CLOUT J, SHU Tang-hua. Improve the oxidizing kinetics of pelletization of magnetite concentrate by high press roll grinding [J]. ISIJ International, 2004, 44(1): 69–73.

ZHU De-qing, PAN Jian, QIU Guan-zhou, CLOUT J, WANG Chang-an, GUO Yu-feng. Mechano-chemical activation of magnetite concentrate for improving its pelletability by high pressure roll grinding [J]. ISIJ International, 2004, 44(2): 3l0–3l5.

ZHU De-qin, TANG Yan-yun, VINICIUS MENDES, PAN Jian, ZHAI Yong. Pretreatment of Brazilian specularite before pelletization by high pressure roller grinding [J]. Metal Mine, 2008(4): 10–11. (in Chinese)

JIANG Tao, ZHANG Yuan-bo, HANG Zhu-cheng, LI Guang-hui, FAN Xiao-hui. Preheating and roasting characteristics of hematite-magnetite (H-M) concentrate pellets [J]. Ironmaking and Steelmaking, 2008, 35(1): 21–23.

TANG Yan-yun. Study of HPRG on PFC specularite pellet [D]. Changsha: Central South University, 2008.

Tavares L M. Particle weakening in high-pressure roll grinding [J]. Minerals Engineering, 2005, 18(7): 651–657.

ZEN Fan, HU Yong-ping, YANG Yi. The principle on mineral process of particle [M]. Xuzhou: China University of Mining and Technology Press, 2001: 16–31. (in Chinese)

XIAO Qi. The theory and production of pellet [M]. Changsha: Central South University of Technology Press, 1990: 106–110. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50725416) supported by the National Natural Science Funds for Distinguished Young Scholars of China

Rights and permissions

About this article

Cite this article

Fan, Jj., Qiu, Gz., Jiang, T. et al. Mechanism of high pressure roll grinding on compression strength of oxidized hematite pellets. J. Cent. South Univ. 19, 2611–2619 (2012). https://doi.org/10.1007/s11771-012-1318-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-012-1318-5