Abstract

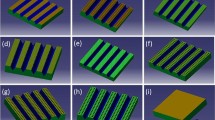

A new approach which adopted the idea of coupling bionics to improve erosion resistance was presented, by taking the desert scorpion as the research object. The anti-erosion characteristic rules and mechanism of desert scorpion’s surface under the dynamics effect of gas/solid mixed media were researched, especially the comprehensive influence mechanism of surface morphology, microstructure, creature flexibility and many other factors was studied. Simulation by CFD software was applied to predict the relative erosion severity. Samples with the coupled bionic configurations and flexibility were produced. Experiment optimum design theory was employed to design experiment scheme. Silica sand of particle size of 105–830 μm was used as the erodent. The erosion tests were carried out to validate the simulation results obtained. It is shown that the predicted results are in agreement with those obtained from the experiment. And contrast tests were carried out at the best and worst test points of erosion resistance for four samples. Contrast tests show that the erosion resistance trend occurs in such order with the best erosion resistance as coupling sample, groove, smooth and flexibility, and smooth, and the increasing rate of erosion resistances in sequence of 12.08%, 8.87%, 6.03% in the best test point. But in the poorest point, the increasing rate of erosion resistance is in sequence of 15.64%, 9.53%, 6.59%. The morphologies of eroded surface were examined by the scanning electron microscope, and the possible wear mechanism was discussed.

Similar content being viewed by others

References

HASSANI S, KLEMBERG-SAPIEHA J E, BIELAWSKI M, BERESC W, MARTINUA L, BALAZINSKI M. Design of hard coating architecture for the optimization of erosion resistance [J]. Wear, 2008, 265(5/6): 879–887.

FENG T, LI H J, FU Q G, YANG X, WU Heng. High-temperature erosion resistance and aerodynamic oxidation mechanism of multi-layer MoSi2-CrSi2-Si/SiC coated carbon/carbon composites in a wind tunnel at 1873 K [J]. Carbon, 2012, 50(6): 2171–2178.

SHIVAMURTHY R C, KAMARAJ M, NAGARAJAN R, SHARIFF S M, PADMANABHAM G. Influence of microstructure on slurry erosive wear characteristics of laser surface alloyed 13Cr-4Ni steel [J]. Wear, 2009, 267(1/2/3/4): 204–212.

BORAWSKI B, SINGH J, TODD JUDITH A, WOLFE DOUGLAS E. Multi-layer coating design architecture for optimum particulate erosion resistance [J]. Wear, 2011, 271(11/12): 2782–2792.

BORAWSKI B, TODD JUDITH A, SINGH J. The influence of ductile interlayer material on the particle erosion resistance of multilayered TiN based coatings [J]. Wear, 2011, 271(11/12): 2890–2898.

HAMED A, TABAKOFF W, WENGLARZ R. Erosion and deposition in turbomachinery [J]. Journal of Propulsion and Power, 2006, 22(2): 350–360.

LIN J Z, SHEN L P, ZHOU Z X. The effect of coherent vortex structure in the particulate two-phase boundary layer on erosion [J]. Wear, 2000, 241(1): 10–16.

FAN J R, LUO K, ZHANG X Y, CEN K C. Large eddy simulation of the anti-erosion characteristics of the ribbed-bend in gas-solid flows [J]. Journal of Engineering for Gas Turbines and Power-Transactions of the ASME, 2004, 126(3): 672–679.

REN L Q, LIANG Y H. Biological couplings: Classification and characteristic rules [J]. Science China Series E: Technological Sciences, 2009, 52(10): 2791–2800.

FET V, POLIS G A, SISSOM W D. Life in sandy deserts: The scorpion model [J]. Journal of Arid Environments, 1998, 39(4): 609–622.

HADLEY N F. Adaptational biology of desert scorpions [J]. Journal of Arachnology, 1974, 2(1): 11–23.

BSC M B, BONNET C M S. Toxicology of androctonus scorpion [J]. British Homoeopathic Journal, 1997, 86(3): 142–151.

ZHU M S, YANG X F. Two species of the genus heterometrus ehrenberg, 1828 (Scorpionidae) from south Vietnamsold in pet shops in china [J]. Acta Arachnologica Sinica, 2007, 16(2): 92–103.

VOLSCHENK E S. A new technique for examining surface morphosculpture of scorpions [J]. The Journal of Arachnology, 2005, 33(3), 820–825.

REN L Q. Progress in the bionic study on anti-adhesion and resistance reduction of terrain machines [J]. Science China Series E: Technological Sciences, 2009, 52(2): 273–284.

SUZUKI M, INABA K, YAMAMOTO M. Numerical simulation of sand erosion phenomena in rotor/stator interaction of compressor [J]. Journal of Thermal Science, 2008, 17(2): 125–133.

SRIVASTAVA V K, PAWAR A G. Solid particle erosion of glass fibre reinforced flyash filled epoxy resin composites [J]. Composites Science and Technology, 2006, 66(15): 3021–3028.

AMAR P, ALOK S, MAHAPATRA S S, DASH R R. Tribo-performance of polyester hybrid composites: Damage assessment and parameter optimization using Taguchi design [J]. Materials and Design, 2009, 30(1): 57–67.

MAHAPATRA S S, AMAR P. Study on mechanical and erosion wear behavior of hybrid composites using Taguchi experimental design [J]. Materials and Design, 2009, 30(8): 2791–2801.

SATAPATHY A, PATNAIK A, PRADHAN M K. A study on processing, characterization and erosion behavior of fish (Labeo-rohita) scale filled epoxy matrix composites [J]. Materials and Design, 2009, 30(7): 2359–2371.

HAN Z W, ZHANG J Q, GE C, JIANG J L, REN L Q. Gas-solid erosion on bionic configuration surface [J]. Journal of Wuhan University of Technology: Materials Science Edition, 2011, 26(2): 306–311.

HAN Z W, ZHANG J Q, GE C, LÜ Y, JIANG J L, LIU Q P, REN L Q. Anti-erosion function in animals and its biomimetic application [J]. Journal of Bionic Engineering, 2010, 7(Supplement): 50–58.

HAN Z W, ZHANG J Q, GE C, LI W, REN L Q. Erosion resistance of bionic functional surfaces inspired from desert scorpions [J]. Langmuir, 2012, 28(5): 2914–2921.

SANDHYARANI B, ALOK S. Tribo-performance analysis of red mud filled glass-epoxy composites using Taguchi experimental design [J]. Materials and Design, 2009, 30(8): 2841–2853.

KIANI A, SHAHBAZI M, ASEMPOUR H. Hydrogel membranes based on gum tragacanth with tunable structure and properties. I. Preparation method using Taguchi experimental design [J]. Journal of Applied Polymer Science, 2012, 124(1): 99–108.

ASILTURK I, NESELI S. Multi response optimisation of CNC turning parameters via Taguchi method-based response surface analysis [J]. Measurement, 2012, 45(4): 785–794.

BARKOULA N M, GREMMELS J, KAEGER K J. Dependence of solid particle erosion on the cross-link density in an epoxy resin modified by hygrothermally decomposed polyurethane [J]. Wear, 2001, 247(1): 100–108.

ARJULA S, HARSHA A P, GHOSH M K. Solid-particle erosion behavior of high-performance thermoplastic polymers [J]. Journal of Materials Science, 2008, 43(6): 1757–1768.

LIANG X. Slurry erosion resistance of alundum reinforced polymer composite material [D]. Dalian: Dalian University of Technology, 2007. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51205161, 51175220, 51290292) supported by the National Natural Science Foundation of China; Projects(20120061120051, 20100061110023) supported by Specialized Research Fund for the Doctoral Program of Higher Education of China; Project(OSR-04-04) supported by Cooperation and Innovation to National Potential Oil and Gas for Production and Research, China; Project(200905016) supported by Ten Outstanding Youth Fund Project of Jilin University, China; Project(2012M511345) supported by China Postdoctoral Science Foundation; Project(450060481176) supported by Basic Scientific Research Expenses of Jilin University, China

Rights and permissions

About this article

Cite this article

Zhang, Jq., Han, Zw., Ma, Rf. et al. Scorpion back inspiring sand-resistant surfaces. J. Cent. South Univ. 20, 877–888 (2013). https://doi.org/10.1007/s11771-013-1561-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-013-1561-4