Abstract

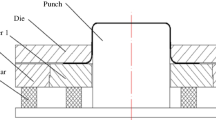

The experimental die apparatus of the solid granules medium forming on sheet metal was designed and manufactured. Typical parts, such as conical, parabolic, cylindrical and square-box-shaped components, were successfully trial-produced as well. According to the analysis of the changing trends of the cross-section shape and the wall thickness during the process, it can be found that the shape of the free deformation zone of the sheet metal, which is the most critical thinning area, can be described as an approximately spherical cap. According to this forming feature, back pressure deep drawing technology with solid granules medium on sheet metal was proposed to restrain drastic thinning at the bottom of the part through the joint friction effect of solid granules medium, the back pressure tringle and the sheet metal. Therefore, the deep drawing limit of the sheet metal is significantly improved. In order to fabricate thin-walled rotary parts with great drawing ratio and complex cross-sections, a finite element model based on the material property test of the solid granules medium was established to optimize the scheme of the back pressure deep drawing. The effects on the forming performance of sheet metal from back pressure load and the approach of blank holding control were analyzed through this model.

Similar content being viewed by others

References

LIN Xin, XU Yong-chao, YUAN Shi-jian. Hydro-forming of aluminum alloy complex-shaped components [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 417–422.

LIN Wei, LIU Gang, CUI Xiao-lei, XU Yong-chao, YUAN Shi-jian. Formability influenced by process loading path of double sheet hydroforming [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 465–469.

WANG Zhong-jin, LIU Jian-guang, LI Yi. Fracture prediction in non-isothermal viscous pressure bulging of aluminum alloy sheet using ductile fracture criterion [J]. Journal of Central South University of Technology, 2010, 17: 449–453.

WANG Zhong-jin, SONG Hui. Effect of electropulsing on anisotropy behaviour of cold-rolled commercially pure titanium sheet [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 409–413.

CHOI H, KOC M, NI J. A study on the analytical modeling for warm hydro-mechanical deep drawing of lightweight materials [J]. International Journal of Machine Tools & Manufacture, 2007, 47: 1752–1766.

LANG L, GU G, LI T, ZHOU X. Numerical and experimental confirmation of the calibration stage’s effect in multi-operation sheet hydroforming using poor-formability materials [J]. Journal of Materials Processing Technology, 2008, 201: 97–100.

PALUMBO G, ZHANG S H, TRICARICO L, XU C, ZHOU L X. Numerical/experimental investigations for enhancing the sheet hydroforming process [J]. International Journal of Machine Tools & Manufacture, 2006, 46: 1212–1221.

XU Yong-chao, LIU Xin, LIU Xiao-jing, YUAN Shi-jian. Deformation and defects in hydroforming of 5A06 aluminum alloy dome with controllable radial pressure [J]. Journal of Central South University of Technology, 2009, 16: 0887–0891.

LIU Xiao-jing, CONG Yan-li, LI Feng, XU Yong-chao, YUAN Shi-jian. Effects of independent radial pressure loading paths on cupthickness distribution [J]. Journal of Central South University: Science and Technology, 2010, 41(3): 917–922. (in Chinese)

WANG Hui-ting, GAO Lin, CHEN Ming-he. Hydrodynamic deep drawing process assisted by radial pressure with inward flowing liquid [J]. International Journal of Mechanical Sciences, 2011, 53: 793–799.

AHMETOGLU M, HUA J, KULUKURU S, ALTAN T. Hydroforming of sheet metal using a viscous pressure medium [J]. Journal of Materials Processing Technology, 2004, 146: 97–107.

WANG Zhong-jin, LI Yi. Formability of 6k21-T4 car panel sheet for viscoselastic-plastic flexible-die forming [J]. Journal of Materials Processing Technology, 2008, 201: 408–412.

LI Yi, WANG Zhong-jin. Finite element analysis of stiffness and static dent resistance of aluminum alloy double-curved panel in viscous pressure forming [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 312–317.

LIU Jiang-guang, WANG Zhong-jin. Prediction of wrinkling and fracturing in viscous pressure forming (VPF) by using the coupled deformation sectional finite element method [J]. Computational Materials Science, 2010, 48: 381–389.

CAO Miao-yan, ZHAO Chang-cai, WU Li-jun, DONG Guo-jiang. Lubricant research on SGMF of magnesium alloy sheet [J]. Advanced Materials Research, 2013, 675: 311–316.

CAO Miao-yan, Dong Guo-jiang, Zhao Chang-cai, SUN Chao, WANG Yin-si. The research on SGMF process applied to metal pipe and sheet metal [C]// 2010 International Conference on Mechanic Automation and Control Engineering. Wuhan, 2010: 5544–5547.

KONG Wei-xue, RUI Yong-qin, DONG Bao-di. Determination of dilatancy angle for geomaterials under non-associated flow rule [J]. Rock and Soil Mechanics, 2009, 30(11): 3278–3282. (in Chinese)

JIANG M J, YAN H B, ZHU H H, UTILI S. Modeling shear behavior and strain localization in cemented sands by two-dimensional distinct element method analyses [J]. Computers and Geotechnics, 2011, 38: 14–29.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(50775197) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Dong, Gj., Zhao, Cc. & Cao, My. Process of back pressure deep drawing with solid granule medium on sheet metal. J. Cent. South Univ. 21, 2617–2626 (2014). https://doi.org/10.1007/s11771-014-2221-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2221-z