Abstract

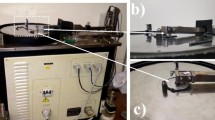

The forming performance of sheet metals in the deep-drawing process with ultrasonic vibrations can be improved by the surface effect between the sheet metal and the die. A sheet metal friction test with ultrasonic vibrations is performed to explore the cause of the surface effect. The frictional characteristics are investigated, and the corresponding friction expressions are established based on the contact mechanics and the elastic—plastic contact model for rough surfaces. Friction is caused by the elastic—plastic deformation of contacting asperities under normal loads. The actual contacting region between two surfaces increases with normal loads, whereas the normal distance decreases. The normal distance between the contacting surfaces is changed, asperities generate a tangential deformation with ultrasonic vibrations, and the friction coefficient is eventually altered. Ultrasonic vibrations are applied on a 40Cr steel punch at the frequency of 20 kHz and the amplitude of 4.2 μm. In the friction tests, the punch is perpendicular to the surface of the magnesium alloy AZ31B sheet metals and is sliding with a relative velocity of 1 mm/s. The test results show that the friction coefficient is decreased by approximately 40% and the theoretical values are in accordance with the test values; Ultrasonic vibrations can clearly reduce wear and improve the surface quality of parts.

摘要

在金属板材超声辅助拉深工艺中,超声激励在板材与模具间所产生的表面效应提高了板材成形 性能。为了探讨表面效应的成因,设计超声振动激励下金属板材摩擦试验,对超声激励下金属板材摩 擦特性进行了研究。同时,基于接触力学理论和粗糙表面弹—塑性接触模型,建立了超声振动激励下 金属板材摩擦力表达式。板材摩擦力起源于接触微凸体承受法向力后产生的弹塑性变形,随着接触力 的增加两个表面间的实际接触面积增加,同时二者间法向距离减小。超声振动改变了接触面间的法向 距离和切向变形,故对摩擦系数产生影响。在垂直于板材表面施加振动频率为20 kHz、振幅为4.2 μm 的超声激励,在相对速度为1 mm/s 的条件下,采用40Cr 压头对AZ31B 镁合金板材进行摩擦试验。 试验结果表明,超声振动使板材摩擦系数降低了大约40%,摩擦系数试验值与理论值基本一致;超声 振动可以减小板材表面划痕,有利于提高其拉深成形件表面质量。

Similar content being viewed by others

References

EAVES A E, SMITH A W, WATERHOUSE W J, SANSOME D H. Review of the application of ultrasonic vibrations to deforming metals [J]. Ultrasonics, 1975, 13(4): 162–170.

KIRCHNER H O K, KROMP W K, PRINZ F B, TRIMMEL P. Plastic deformation under simultaneous cyclic and unidirectional loading at low and ultrasonic frequencies [J]. Materials Science and Engineering, 1985, 68(2): 197–206.

LEE K H, LEE S K, KIM B M. Advanced simulation of die wear caused by wire vibrations during wire-drawing process [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1723–1731.

NGAILE G, BUNGET C. Influence of ultrasonic vibration on microforming [J]. Transactions of NAMRI/SME, 2008, 36: 137–144.

STORCK H, LITTMANN W, WALLASCHEK J, MRACEK M. The effect of friction reduction in presence of ultrasonic vibrations and its relevance to travelling wave ultrasonic motors [J]. Ultrasonics, 2002, 40: 379–383.

KUMAR V C, HUTCHINGS I M. Reduction of the sliding friction of metals by the application of longitudinal or transverse ultrasonic vibration [J]. Tribology International, 2004, 37(10): 833–840.

LITTMANN W, STORCK H, WALLASCHEK J. Sliding friction in the presence of ultrasonic oscillations: Superposition of longitudinal oscillations [J]. Archive of Applied Mechanics, 2001, 71(8): 549–554.

DONG S, DAPINO M J. Piezoelectrically-induced ultrasonic lubrication by way of Poisson effect [J]. Proc Spie, 2012, 8343: 83430L.

DONG S, DAPINO M J. Elastic–plastic cube model for ultrasonic friction reduction via Poisson’s effect [J]. Ultrasonics, 2014, 54: 343–350.

POPOV V L, STARCEVIC J, FILIPPOV A E. Influence of ultrasonic in-plane oscillations on static and sliding friction and intrinsic length scale of dry friction processes [J]. Tribology Letters, 2010, 39(1): 25–30.

HE Yu-hui, ZHOU Qun, ZHOU Jian-jie, LANG Xian-jun. Comprehensive modeling approach of axial ultrasonic vibration grinding force [J]. Journal of Central South University, 2016, 23(3): 562–569.

HUANG Y M, WU Y S, HUANG J Y. The influence of ultrasonic vibration-assisted micro-deep drawing process [J]. International Journal of Advanced Manufacturing Technology, 2014, 71(5–8): 1455–1461.

JIMMA T, KASUGA Y, IWAKI N, MIYAZAWA O, MORI E, ITO K, HATANO H. An application of ultrasonic vibration to the deep drawing process [J]. Journal of Materials Processing Technology, 1998, 80–81: 406–412.

CAO Miao-yan, LI Jian-chao, YUAN Ya-ning, ZHAO Chang-cai. Flexible die drawing of magnesium alloy sheet by superimposing ultrasonic vibration [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 163–171.

WEN Tong, GAO Rui, CHEN Xia. Influence of high frequency vibration on deep drawing process of AZ31 sheet at room temperature [J]. Journal of Shanghai Jiao Tong University: Science, 2012, 17(4): 456–460. (in Chinese)

SIDDIQ A, SAYED T E. Ultrasonic-assisted manufacturing processes: Variational model and numerical simulations [J]. Ultrasonics, 2012, 52(4): 521–529.

ASHIDA Y, AOYAMA H. Press forming using ultrasonic vibration [J]. Journal of Materials Processing Technology, 2007, 187–188(3): 118–122.

GREENWOOD J A, WILLIAMSON J B P. Contact of nominally flat surfaces [J]. Proceedings of the Royal Society A: Mathematical Physical and Engineering Sciences, 1966, 295(1442): 300–319.

COHEN D, KLINGERMAN Y, ETSION I. A model for contact and static friction of nominally flat rough surfaces under full stick contact condition [J]. Journal of Tribology, 2008, 130(3): 117–139.

CHANG W R, ETSION I, BOGY D B. An elastic-plastic model for the contact of rough surfaces [J]. Journal of Tribology, 1987, 109(2): 257–263.

POLYCARPOU A A, ETSION I. Analytical approximations in modeling contacting rough surfaces [J]. Journal of Tribology, 1999, 121(2): 234–239.

DAHL P. A Solid friction model [R]. Los Angeles: Aerospace Corp El Segundo Ca, 1968.

CRAIG R C. Mechanics of materials [M]. New York: John Wiley & Sons, 2000.

SIEGERT K, ULMER J. Influencing the friction in metal forming processes by superimposing ultrasonic waves [J]. CIRP Annals-Manufacturing Technology, 2001, 50(1): 195–200.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51775480, 51305385) supported by the National Natural Science Foundation of China; Project (E2018203143) supported by the Natural Science Foundation of Hebei Province, China

Rights and permissions

About this article

Cite this article

Cao, My., Li, Jc., Liu, Yy. et al. Frictional characteristics of sheet metals with superimposed ultrasonic vibrations. J. Cent. South Univ. 25, 1879–1887 (2018). https://doi.org/10.1007/s11771-018-3877-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3877-6