Abstract

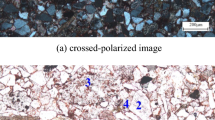

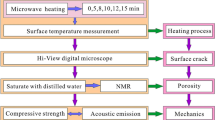

Traditional mechanical rock breaking method is labor-intensive and low-efficient, which restrictes the development of deep resources and deep space. As a new rock-breakage technology, microwave irradiation is expected to overcome these problems. This study examines the failure characteristics, weakening law, and breakdown mechanism of deep sandstone (depth=1050 m) samples in a microwave field. The macroscopic and microscopic properties were determined via mechanical tests, mesoscopic tests, and numerical simulations. Microwave application at 1000 W for 60 s reduced the uniaxial compressive strength of the sandstone by 50%. Thermal stress of the sandstone was enhanced by uneven expansion of minerals at the microscale. Moreover, the melting of some minerals in the high-temperature environment changed the pore structure, sharply reducing the macroscopic strength. The temperature remained high in the lower midsection of the sample, and the stress was concentrated at the bottom of the sample and along its axis. These results are expected to improve the efficiency of deep rock breaking, provide theoretical and technical support for similar rock-breakage projects, and accelerate advances in deep-Earth science.

摘要

传统的机械破岩方法劳动强度大, 效率低, 制约了深部资源和深部空间的开发。而微波技术作 为一种新型破岩手段有望破解此类难题。本文从宏观到细观综合运用力学测试, 细观试验以及数值模 拟等手段探讨了微波场内埋深1050 m砂岩试样的破坏特征, 弱化规律及破裂机制。研究表明, 微波作 用下砂岩单轴抗压强度会大幅降低, 当1000 W功率作用60 s 时, 强度折减幅度可达50%; 结合单轴和 细观试验发现, 矿物不均匀膨胀导致砂岩内部热应力增大的同时, 高温环境下部分矿物会同步发生熔融, 从而使试样内部孔裂隙结构发生急剧改变然后体现为强度的大幅下降微波场内试样的中下部温 度较高, 高应力区出现在试样底部并沿轴向扩展。本文研究结果将为类似岩石破碎工程提供破岩理论 依据与技术支撑。

Similar content being viewed by others

References

GAO Ming-zhong, HAO Hai-chun, XUE Shou-ning, et al. Discing behavior and mechanism of cores extracted from Songke-2 well at depths below 4500 m [J]. International Journal of Mining Science and Technology, 2022, 149: 104976. DOI: https://doi.org/10.1016/j.ijrmms.2021.104976.

GAO Ming-zhong, ZHANG Zhi-long, YIN Xian-gang, et al. The location optimum and permeability-enhancing effect of a low-level shield rock roadway [J]. Rock Mechanics and Rock Engineering, 2018, 51(9): 2935–2948. DOI: https://doi.org/10.1007/s00603-018-1461-x.

GAO Ming-zhong, ZHANG Jian-guo, LI Sheng-wei, et al. Calculating changes in the fractal dimension of surface cracks to quantify how the dynamic loading rate affects rock failure in deep mining [J]. Journal of Central South University, 2020, 27(10): 3013–3024. DOI: https://doi.org/10.1007/s11771-020-4525-5.

GAO Ming-zhong, XIE Jing, GAO Ya-nan, et al. Mechanical behavior of coal under different mining rates: A case study from laboratory experiments to field testing [J]. International Journal of Mining Science and Technology, 2021, 31(5): 825–841. DOI: https://doi.org/10.1016/j.ijmst.2021.06.007.

ZHENG Yan-long, HE Lei. TBM tunneling in extremely hard and abrasive rocks: Problems, solutions and assisting methods [J]. Journal of Central South University, 2021, 28(2): 454–480. DOI: https://doi.org/10.1007/s11771-021-4615-z.

ZHENG Yan-long, ZHANG Qian-bing, ZHAO Jian. Challenges and opportunities of using tunnel boring machines in mining [J]. Tunnelling and Underground Space Technology, 2016, 57: 287–299. DOI: https://doi.org/10.1016/j.tust.2016.01.023.

ALI A Y, BRADSHAW S M. Quantifying damage around grain boundaries in microwave treated ores [J]. Chemical Engineering and Processing: Process Intensification, 2009, 48(11, 12): 1566–1573. DOI: https://doi.org/10.1016/j.cep.2009.09.001.

LU Gao-ming, LI Yuan-hui, HASSANI F, et al. The influence of microwave irradiation on thermal properties of main rock-forming minerals [J]. Applied Thermal Engineering, 2017, 112: 1523–1532. DOI: https://doi.org/10.1016/j.applthermaleng.2016.11.015.

ZHENG Yan-long, ZHAO Xiao-bao, ZHAO Qin-hua, et al. Dielectric properties of hard rock minerals and implications for microwave-assisted rock fracturing [J]. Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2020, 6(1): 1–17. DOI: https://doi.org/10.1007/s40948-020-00147-z.

ZHAO Qin-hua, ZHAO Xiao-bao, ZHENG Yan-long, et al. A review on mineral heating characteristics and rock weakening effect under microwave irradiation [J]. Geological Journal of China Universities, 2020, 26(3): 350–360. DOI: https://doi.org/10.16108/j.issn1006-7493.2019041. (in Chinese)

KINGMAN S W, CORFIELD G M, ROWSON N A. Effects of microwave radiation upon the mineralogy and magnetic processing of a massive Norwegian ilmenite ore [J]. Magnetic and Electrical Separation, 1999, 9(3): 131–148. DOI: https://doi.org/10.1155/1999/57075.

KINGMAN S W, VORSTER W, ROWSON N A. The influence of mineralogy on microwave assisted grinding [J]. Minerals Engineering, 2000, 13(3): 313–327. DOI: https://doi.org/10.1016/S0892-6875(00)00010-8.

LU Gao-ming, FENG Xia-ting, LI Yuan-hui, et al. Experimental investigation on the effects of microwave treatment on basalt heating, mechanical strength, and fragmentation [J]. Rock Mechanics and Rock Engineering, 2019, 52(8): 2535–2549. DOI: https://doi.org/10.1007/s00603-019-1743-y.

NEJATI H, HASSANI F, RADZISZEWSKI P. Experimental investigation of fracture toughness reduction and fracture development in basalt specimens under microwave illumination [C]// Thirteenth ASCE Aerospace Division Conference on Engineering, Science, Construction, and Operations in Challenging Environments, and the 5th NASA/ASCE Workshop On Granular Materials in Space Exploration. Reston, VA, USA: American Society of Civil Engineers, 2012: 325–334. DOI: https://doi.org/10.1061/9780784412190.036.

LIU Jian-zhong, ZHU Jie-feng, CHENG Jun, et al. Pore structure and fractal analysis of Ximeng lignite under microwave irradiation [J]. Fuel, 2015, 146: 41–50. DOI: https://doi.org/10.1016/j.fuel.2015.01.019.

LI He, SHI Shi-liang, LIN Bai-quan, et al. Effects of microwave-assisted pyrolysis on the microstructure of bituminous coals [J]. Energy, 2019, 187: 115986. DOI: https://doi.org/10.1016/j.energy.2019.115986.

GAO Ming-zhong, ZHANG Sheng, LI Jie, et al. The dynamic failure mechanism of coal and gas outbursts and response mechanism of support structure [J]. Thermal Science, 2019, 23(S3): 867–875. DOI: https://doi.org/10.2298/tsci180610122g.

XIE Jing, GAO Ming-zhong, ZHANG Ru, et al. Gas flow characteristics of coal samples with different levels of fracture network complexity under triaxial loading and unloading conditions [J]. Journal of Petroleum Science and Engineering, 2020, 195: 107606. DOI: https://doi.org/10.1016/j.petrol.2020.107606.

LI Yuan-hui, LU Gao-ming, FENG Xia-ting, et al. The influence of heating path on the effect of hard rock fragmentation using microwave assisted method [J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(6): 1460–1468. DOI: https://doi.org/10.13722/j.cnki.jrme.2016.1229. (in Chinese)

SATISH H, OUELLET J, RAGHAVAN V, et al. Investigating microwave assisted rock breakage for possible space mining applications [J]. Mining Technology, 2006, 115(1): 34–40. DOI: https://doi.org/10.1179/174328606X101902.

ZHAO Jian, ZHENG Yan-long, ZHANG Qian-bing, et al. Rock fracturing by low power microwave treatment-observations, mechanisms and applications [C]// International Society for Rock Mechanics and Rock Engineering. 2018.

ZHENG Y L, ZHANG Q B, ZHAO J. Effect of microwave treatment on thermal and ultrasonic properties of gabbro [J]. Applied Thermal Engineering, 2017, 127: 359–369. DOI: https://doi.org/10.1016/j.applthermaleng.2017.08.060.

PEINSITT T, KUCHAR F, HARTLIEB P, et al. Microwave heating of dry and water saturated basalt, granite and sandstone [J]. International Journal of Mining and Mineral Engineering, 2010, 2(1): 18–29. DOI: https://doi.org/10.1504/ijmme.2010.031810.

HARTLIEB P, LEINDL M, KUCHAR F, et al. Damage of basalt induced by microwave irradiation [J]. Minerals Engineering, 2012, 31: 82–89. DOI: https://doi.org/10.1016/j.mineng.2012.01.011.

HASSANI F, NEKOOVAGHT P M, GHARIB N. The influence of microwave irradiation on rocks for microwave-assisted underground excavation [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2016, 8(1): 1–15. DOI: https://doi.org/10.1016/j.jrmge.2015.10.004.

HARTLIEB P, KUCHAR F, MOSER P, et al. Reaction of different rock types to low-power (3.2 kW) microwave irradiation in a multimode cavity [J]. Minerals Engineering, 2018, 118: 37–51. DOI: https://doi.org/10.1016/j.mineng.2018.01.003.

HARTLIEB P, GRAFE B. Experimental study on microwave assisted hard rock cutting of granite [J]. BHM Berg-Und Hüttenmännische Monatshefte, 2017, 162(2): 77–81. DOI: https://doi.org/10.1007/s00501-016-0569-0.

MENZHULIN M G, MAKHMUDOV K F. Analysis of the dependence of the break-down point on temperature of microwave heating of loaded heterogeneous materials (rocks) based on the formation of growth of microcracks [J]. Technical Physics, 2019, 64(5): 615–619. DOI: https://doi.org/10.1134/S1063784219050153.

GONG Feng-qiang, SI Xue-feng, LI Xi-bing, et al. Dynamic triaxial compression tests on sandstone at high strain rates and low confining pressures with split Hopkinson pressure bar [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 113: 211–219. DOI: https://doi.org/10.1016/j.ijrmms.2018.12.005.

LU Gao-ming, FENG Xia-ting, LI Yuan-hui, et al. Influence of microwave treatment on mechanical behaviour of compact basalts under different confining pressures [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2020, 12(2): 213–222. DOI: https://doi.org/10.1016/j.jrmge.2019.06.009.

MEISELS R, TOIFL M, HARTLIEB P, et al. Microwave propagation and absorption and its thermo-mechanical consequences in heterogeneous rocks [J]. International Journal of Mineral Processing, 2015, 135: 40–51. DOI: https://doi.org/10.1016/j.minpro.2015.01.003.

JONES D A, KINGMAN S W, WHITTLES D N, et al. The influence of microwave energy delivery method on strength reduction in ore samples [J]. Chemical Engineering and Processing: Process Intensification, 2007, 46(4): 291–299. DOI: https://doi.org/10.1016/j.cep.2006.06.009.

TOIFL M, MEISELS R, HARTLIEB P, et al. 3D numerical study on microwave induced stresses in inhomogeneous hard rocks [J]. Minerals Engineering, 2016, 90: 29–42. DOI: https://doi.org/10.1016/j.mineng.2016.01.001.

TOIFL M, HARTLIEB P, MEISELS R, et al. Numerical study of the influence of irradiation parameters on the microwave-induced stresses in granite [J]. Minerals Engineering, 2017, 103–104: 78–92. DOI: https://doi.org/10.1016/j.mineng.2016.09.011.

ZHANG Zhao-peng, XIE He-ping, ZHANG Ru, et al. Deformation damage and energy evolution characteristics of coal at different depths [J]. Rock Mechanics and Rock Engineering, 2019, 52(5): 1491–1503. DOI: https://doi.org/10.1007/s00603-018-1555-5.

GONG Feng-qiang, ZHAO Gao-feng. Dynamic indirect tensile strength of sandstone under different loading rates [J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 2271–2278. DOI: https://doi.org/10.1007/s00603-013-0503-7.

GAO M Z, ZHANG R, XIE J, et al. Field experiments on fracture evolution and correlations between connectivity and abutment pressure under top coal caving conditions [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 111: 84–93. DOI: https://doi.org/10.1016/j.ijrmms.2018.01.003.

XIE He-ping. Fractal in rock mechanics [M]. Beijing: Science Press, 1996. (in Chinese)

LI He. Thermodynamical response of coal and the hydraulic-mechanical coupling mechanism under microwave irradiation [D]. Xuzhou: China University of Mining and Technology, 2018. (in Chinese)

LIN Bai-quan, LI He, CHEN Zhong-wei, et al. Sensitivity analysis on the microwave heating of coal: A coupled electromagnetic and heat transfer model [J]. Applied Thermal Engineering, 2017, 126: 949–962. DOI: https://doi.org/10.1016/j.applthermaleng.2017.08.012.

WANG Wen-long. Research and simulation analysis of electromagnetic distribution of microwave heating cavity [D]. Changsha: Hunan University, 2015. (in Chinese)

HARTLIEB P, TOIFL M, KUCHAR F, et al. Thermophysical properties of selected hard rocks and their relation to microwave-assisted comminution [J]. Minerals Engineering, 2016, 91: 34–41. DOI: https://doi.org/10.1016/j.mineng.2015.11.008.

KAHRAMAN S, CANPOLAT A N, FENER M. The influence of microwave treatment on the compressive and tensile strength of igneous rocks [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 129: 104303. DOI: https://doi.org/10.1016/j.ijrmms.2020.104303.

Funding

Projects(51822403, 51827901) supported by the National Natural Science Foundation of China; Project(2018HH0159) supported by the Sichuan International Technological Innovation Cooperation, China

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

The overarching research goals were developed by GAO Ming-zhong, XIE Jing and YANG Ben-gao. YANG Ben-gao, LIU Jun-jun and WANG Fei carried out the microwave irradiation experiment, then recorded and analyzed the phenomena and data. YANG Ben-gao, WANG Xuan and WENG Xiang-yue established the model of microwave irradiation, and analyzed the distribution characteristics of electric field, temperature field and stress field in the microwave field. The mesoscopic tests of the sandstone were completed by WANG Ming-yao and YANG Zhao-ying. YANG Ben-gao and LIU Jun-jun analyzed the calculated results. The initial draft of the manuscript was written by YANG Ben-gao, GAO Ming-zhong and XIE Jing. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

The authors declare no conflict of interests.

Rights and permissions

About this article

Cite this article

Yang, Bg., Gao, Mz., Xie, J. et al. Exploration of weakening mechanism of uniaxial compressive strength of deep sandstone under microwave irradiation. J. Cent. South Univ. 29, 611–623 (2022). https://doi.org/10.1007/s11771-022-4910-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4910-3