Abstract

GLARE (glass-reinforced aluminum laminate) is a new class of fiber metal laminates for advanced aerospace structural applications. It consists of thin aluminum sheets bonded together with unidirectional or biaxially reinforced adhesive prepreg of high-strength glass fibers. GLARE laminates offer a unique combination of properties such as outstanding fatigue resistance, high specific static properties, excellent impact resistance, good residual and blunt notch strength, flame resistance and corrosion properties, and ease of manufacture and repair. GLARE laminates can be tailored to suit a wide variety of applications by varying the fiber/resin system, the alloy type and thickness, stacking sequence, fiber orientation, surface pretreatment technique, etc. This article presents a comprehensive overview of the mechanical properties of various GLARE laminates under different loading conditions.

Similar content being viewed by others

References

C.A.J.R. Vermeeren, “An Historic Overview of the Development of Fiber Metal Laminates,” Appl. Comp. Mater., 10 (2003), pp. 189–205.

A. Volt, L.B. Vogelesang, and T.J. de Vries, “Towards Application of Fiber Metal Laminates in Larger Aircraft,” Aircraft Eng. & Aerospace Technol., 71 (6) (1999), pp. 558–570.

L.B. Vogeslang and A. Volt, “Development of Fibre Metal Laminates for Advanced Aerospace Materials,” J. of Mater. Processing Technol., 103 (2000), pp. 1–5.

S. Krishnakumar, “Fiber Metal Laminates—The Synthesis of Metals and Composites,” Materials and Manufacturing Processing, 9 (2) (1995), pp. 295–354.

A. Afaghi-Khatibi, L. Ye, and Y.W. Mai, “Hybrids and Sandwiches,” Comprehensive Composite Materials, 2 (2000), pp. 249–290.

E. Li and W.S. Johnson, “An Investigation into the Fatigue of Hybrid Titanium Composite Laminate,” J. of Comp. Technol., 20 (1) (1998), pp. 3–12.

Dennis A. Burianek and S.M. Spearing, “Delamination Growth Face Sheet Seams in Cross-Ply Titanium/Graphite Hybrid Laminates,” Comp. Sci. and Tech., 61 (2000), pp. 261–269.

H.J.M. Woerden, J. Sinke, and P.A. Hooimeijer, “Maintenance of GLARE Structures and GLARE as Riveted or Bonded Repair Material,” Appl. Comp. Mater., 10 (2003), pp. 307–329.

C.A.J.R. Vermeeren et al., “Glare Design Aspects and Philosophies,” Appl. Comp. Mater., 10 (2003), pp. 257–276.

J.W. Gunnink and L.B. Vogelesang, Proceedings of the 35th International SAMPE Symposium (Covina, CA: SAMPE, 1990), pp. 1708–1721.

J.W. Gunnink and L.B. Vogelesang, Proceedings of the 36th International SAMPE Symposium and Exhibition (Covina, CA: SAMPE, 1991), pp. 1509–1522.

R.J. Bucci and L.N. Muller, Treatise on Materials Science and Technology, Vol. 31A, ed. K. Vasudevan and R.D. Doherty (San Diego, CA: Academic Press Inc., 1989), pp. 295–322.

H.F. Wu, “Use of the Rule of Mixtures and Metal Volume Fraction for Mechanical Property Predictions of Fiber-Reinforced Aluminum Laminates,” J. of Mater. Sci., 29 (1994), pp. 4583–4591.

M. Hangenbeek et al., “Static Properties of Fiber Metal Laminates,” Appl. Comp. Mater., 10 (2003), pp. 207–222.

Guocai Wu and Jenn-Ming Yang, “Analytical Modeling and Numerical Simulation of Nonlinear Deformation of Hybrid Fiber Metal Laminates,” submitted to Modeling and Simulation in Mater. Sci. and Eng. (2004).

M. Kawai et al., “Inelastic Deformation Behavior and Strength of Fiber-Metal Hybrid Composite: GLARE,” Int. J. Mech. Sci., 40 (2) (1998), pp. 183–198.

M.A. Gegory, Proceedings of the 30th Annual CIM Conference of Metallurgists (Ottawa, Canada: CIM, 1991), p. 4410.

J.L. Verolme, Compressive Properties of GLARE, Report LR-666 (Delft, Netherlands: Delft University of Technology, 1991).

J. Cook and M.E. Donnellan, Tensile and Interlaminar Properties of GLARE Laminates, Report NADC-91087-60 (Warminster, PA: Naval Air Development Center, 1991).

E. Holleman, “Bearing Strength Prediction for Some GLARE Grades,” Memorandum M-683 (Delft, Netherlands: Delft University of Technology, November 1994).

W.J. Slager, “On the Bearing Strength of Fiber Metal Laminates,” J. of Comp. Mater., 6 (17) (1992), pp. 2542–2566.

H.F. Wu, “An Investigation on the Bearing Test Procedure for Fiber-Reinforced Aluminum Laminates,” J. of Mater. Sci., 29 (1994), pp. 4592–4603.

J.L. Teply, B. Diapolo and R.J. Bucci, Proceedings of the 19th International SAMPE Technical Conference (Covina, CA: SAMPE, 1987), pp. 353–359.

Y. Macheret and T.L. Teply, Proceedings of the Joint ASME/SES Applied Mechanics and Engineering Sciences Conference (NY: ASME, 1988), p. 53.

C.A.J.R. Vermeeren, L.B. Vogelesang, and J.W. Gunnink, Proceedings of the ESA Symposium on Space Applications of Advanced Structural Materials (European Space Agency, June 1990), p. 313

J. Macheret and R.J. Bucci, “A Crack Growth Resistance Curve Approach to Fiber/Metal Laminate Fracture Toughness Evaluation,” Eng. Fract. Mech., 45 (6) (1993), pp. 729–739.

C.A.J.R. Vermeeren, Residual Strength Predictions for Fiber Metal Laminates: The R-curve Approach, Report LR-717 (Delft, Netherlands: Delft University of Technology, 1993).

R.C. Alderliesten et al., “Fatigue and Damage Tolerance of Glare,” Appl. Comp. Mater., 10 (2003), pp. 223–242.

P.A. Lagace and D.S. Cairns, Proceedings of the 33rd International SAMPE Symposium and Exhibition (Covina, CA: SAMPE, 1987), pp. 720–726.

C.A.J.R. Vermeeren, Blunt Notch Behavior of Fiber Metal Laminates: ARALL and GLARE, Report LR-617 (Delft, Netherlands: Delft University of Technology, January 1990).

E. Holleman and T.J. de Vries, “Residual Strength of Some Grades as Function of Specimen Geometry,” Memorandum M-717 (Delft, Netherlands: Delft University of Technology, 1995).

T. J. de Vries, “The Influence of the Constituent Properties on the Residual Strength of GLARE,” Appl. Comp. Mater., 8 (2001), pp. 263–277.

C.A.J.R. Vereeren, “The Residual Strength of Fiber Metal Laminates: GLARE2 and GLARE3,” Proceedings of the 30th International SAMPE Technical Conference (Covina, CA: SAMPE, 1998), pp. 471–483.

P.K. Govindan Potti, B. Nageswararao, and V.K. Srivastava, “Notched Tensile Strength of Various Fiber Reinforced Metal Laminates,” Adv. Comp. Mater., 9 (3) (2000), pp. 187–206.

G.D. Lawcock, L. Ye, and Y.-W. Mai, “Progressive Damage and Residual Strength of a Carbon Fiber Reinforced Metal Laminate,” J. Comp. Mater., 31 (1997), pp. 762–787.

Guocai Wu and Jenn-Ming Yang, “Blunt Notch Behavior of GLARE Laminates,” Proceedings of the 49th International SAMPE Symposium and Exhibition (Covina, CA: SAMPE, 2004).

Z.H. Jin and R.C. Batra, “Residual Strength of Centrally Cracked Metal/Fiber Composite Laminates,” Mater. Sci. and Eng., A216 (1996), pp. 117–124.

A. Afaghi-Khatibi, L. Ye, and Y.-W. Mai, “An Effective Crack Growth Model for Residual Strength Evaluation of Composite Laminates with Circular Holes,” J. Comp. Mater., 30 (1996), pp. 142–163.

A. Afaghi-Khatibi, L. Ye, and Y.W. Mai, “Evaluation of Effective Crack Growth and Residual Strength of Fiber-Reinforced Metal Laminates with a Sharp Notch,” Comp. Sci. and Tech., 56 (1996), pp. 1079–1088.

J.B. Young, J.G.N. Landry, and V.N. Cavoulacos, “Crack Growth and Residual Strength Characteristics of Two Grades of GLARE,” Composites Structures, 29 (1994), pp. 457–469.

T. Takamatsu et al., “Fatigue Crack Growth Properties of a GLARE3-5/4 Fiber/Metal Laminate,” Eng. Fract. Mech., 63 (1999), pp. 253–272.

P. Horst, and N. Ohrloff, “The Influence of Pre-Stretching and Temperature on the Static and Damage Tolerance Behavior of GLARE Material,” Proceedings of ICCM-IX, Vol. 4, ed. Antonio Miravete (1993), pp. 182–188.

M. Papakyriacou, J. Schijve, and S.E. Stanzl-Tschegg, “Fatigue Crack Growth Behavior of Fiber-Metal Laminate GLARE-1 and Metal Laminate 7475 with Different Blunt Notches,” Fatigue & Fracture Eng. Mater. Struc., 20 (11) (1997), pp. 1573–1584.

M. Papakyriacou et al., “Fatigue Crack Growth in GLARE, Role of Glass Fibers,” Proc. of 10th Europ. Conf. Fract., Vol. 2 (West Midlands, UK: Warley, 1994), pp. 1193–1199.

A. Vasak, J. Polak, and V. Kozak, “Fatigue Crack Initiation in Fibre-Metal Laminate GLARE 2,” Mater. Sci. and Eng., A234–236 (1997), pp. 621–624.

M. Kawai and A. Hachinohe, “Two-Stress Level Fatigue of Unidirectional Fiber-Metal Hybrid Composite: GLARE 2,” Inter. J. of Fatigue, 24 (2002), pp. 567–580.

J.R. Yeh, “Fracture Crack Growth in Fiber-Metal Laminates,” Int. J. Solids Structures, 32 (14) (1995), pp. 2063–2075.

L.B. Vogelesang, J. Schijve, and R. Fredell, “Fiber Metal Laminates: Damage Tolerant Aerospace Materials,” Case Studies in Manufacturing with Advanced Materials, Vol. 2, ed. A. Demaid and J.H.W. de Wit (Amsterdam: Elsevier, 1995), pp. 253–271.

R. Marissen, “Fatigue Mechanisms in ARALL, a Fatigue Resistant Hybrid Aluminum Aramid Composite Material,” Fatigue’ 87 (1987), pp. 1271–1279.

R.O. Ritchie, W. Yu, and R.J. Bucci, “Fatigue Crack Propagation in ARALL Laminates: Measurement of the Effect of Crack-Tip Shielding from Crack Bridging,” Eng. Fract. Mech., 32 (1989), pp. 361–377.

R. Marissen (Ph.D. thesis, Delft University of Technology, 1988).

J. Schijve, “Development of Fiber-Metal Laminate (ARALL and GALE), New Fatigue Resistant Materials,” Fatigue 93, pp. 3–20.

K.J. Cain and C.L. Tan “Numerical Modeling of Fiber-Bridging in Cracked Fiber-Metal Laminates,” J. Advanced Mater., 28 (2) (1997), pp. 8–15.

Y.J. Guo and X.R. Wu, “A Phenomenological Model for Predicting Crack Growth in Fiber-Reinforced Metal Laminates under Constant-Amplitude Loading,” Comp. Sci. and Tech., 59 (1999), pp. 1825–1831.

D. J. Shim et al., “Fatigue Crack Growth Prediction of GLARE Hybrid Laminates,” Comp. Sci. and Eng., 63 (2003), pp. 1759–1767.

Y.J. Guo and X.R. Wu, “A Theoretical Model for Predicting Fatigue Crack Growth in Fiber-Reinforced Metal Laminates,” Fatigue & Fracture Eng. Mater. Struc., 21 (1998), pp. 1133–1145.

Y.J. Guo and X.R. Wu, “Bridging Stress Distribution in Center-Cracked Fiber Reinforced Metal Laminate: Modeling and Experiment,” Eng. Fract. Mech., 63 (1999), pp. 147–163.

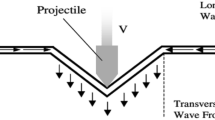

A. Vlot, “Impact Properties of Fiber Metal Laminates,” Composites Eng., 3 (10) (1993), pp. 911–927.

A. Vlot, “Impact Loading on Fiber Metal Laminates,” Int. J. Impact Eng., 18 (3) (1996), pp. 291–307.

A. Vlot, E. Kroon, and G.L. Rocca, “Impact Response of Fiber Metal Laminates,” Key Eng. Mater., 141–143 (1998), pp. 235–276.

A. Fahr et al., “Non-Destructive Evaluation Methods for Damage Assessment in Fiber-Metal Laminates,” Polymer Comp., 21 (2000), pp. 568–575.

Guocai Wu and Jenn-Ming Yang, “Impact Behavior of GLARE Laminates,” Proceedings of the 36th International SAMPE Technical Conference (Covina, CA: SAMPE, November 2004).

J.F. Laliberte et al., “Post-Impact Fatigue Damage Growth in Fiber-Metal Laminates,” Inter. J. of Fatigue, 24 (2002), pp. 249–256.

J.J. Homan, Compression after Impact, Report B2v-98-11 (Delft, Netherlands: Delft University of Technology, December 1998).

T. Beumler et al., “Environmental Influence on GLARE Riveted Joints,” Proceedings of the 46th International SAMPE Symposium, Vol. 35, No. 2 (Covina, CA: SAMPE, 2001), pp. 389–401.

M.F.H.C. Boertien, “Strength of GLARE after Exposure to Moisture” (Thesis report, Faculty of Aerospace Engineering, Delft University of Technology, 1996).

B. Borgonje and M.S. Ypma, “Long Term Behavior of GLARE,” Appl. Comp. Mater., 10 (2003), pp. 243–255.

Author information

Authors and Affiliations

Additional information

For more information, contact J.-M. Yang, University of California, Department of Materials Science and Engineering, 6532 Boelter Hall, Los Angles, CA 90024; (310) 825-2758; fax (310) 206-7353; e-mail jyang@seas.ucla.edu.

Rights and permissions

About this article

Cite this article

Wu, G., Yang, J.M. The mechanical behavior of GLARE laminates for aircraft structures. JOM 57, 72–79 (2005). https://doi.org/10.1007/s11837-005-0067-4

Issue Date:

DOI: https://doi.org/10.1007/s11837-005-0067-4