Abstract

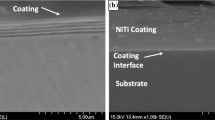

Improvements to an Ni-(5–6 wt.%)B coating have resulted in exceptional hardness and wear resistance that meet or exceed many of the performance standards set by hard chromium. Currently, no other bath plating technologies offer properties competitive with hard chromium, including electroless nickel-phosphorous derivatives and older versions of Ni-B. In this article, the improved Ni-B is discussed in terms of microstructural features, performance properties, coating methodology, and applications.

Similar content being viewed by others

References

E. Brooman, “Wear Behavior of Environmentally Acceptable Alternatives to Chromium Coatings: Nickel-Based Candidates,” Metal Finishing, 102 (9) (2004), pp. 75–82.

E. McComas, U.S. patent 4,833,041.

T. Gaevskaya, I. Novotortseva, and L. Tsybulskaya, “The Effect of Boron on the Microstructure and Properties of Electrodeposited Nickel Films,” Metal Finishing (June 1996), pp. 100–103.

P. Panissod, I. Bakonyi, and R. Hasegawa, “NMR Study of the Boron Coordination in Ni100-xBx Metallic Glass,” J. Magnetism and Magnetic Materials, 31–34 (1983), pp. 1523–1524.

F. Delaunois and P. Lienard, “Heat Treatments for Electroless Nickel-Boron Plating on Aluminum Alloys,” Surface and Coatings Technology, 160 (2002), pp. 239–248.

P. Kumar and P. Nair, “X-ray Diffraction Studies on the Relative Proportion and Decomposition of Amorphous Phase in Electroless Ni-B Deposits,” Nanostructured Materials, 4 (2) (1994), pp. 183–198.

T. Narayanan and S. Seshadri, “Formation and Characterization of Borohydride Reduced Electroless Nickel Deposits,” J. Alloys and Compounds, 365 (2004), pp. 197–205.

C. Devros, J. Novakovic, and P. Vassiliou, “Vacuum Heat Treatment of Electroless Ni-B Coatings,” Materials Letters, 58 (2004), pp. 619–623.

F. Delaunois et al., “Autocatalytic Electroless Nickel-Boron Plating on Light Alloys,” Surface and Coating Technology, 124 (2000), pp. 201–209.

G. Gawrilov, Chemical (Electroless) Nickel Plating (Surrey: Portcullis Press, 1979), pp. 57–97.

Technical information about electroless of chemical nickel plating by the Nibodur method, Paul Anke, Essen, West Germany.

M. Mathiselvam, B. Sivasankar, and T. Narayanan, Proceedings of the Interfinish-2002, Section VII: Electroless Nickel (Mumbai, India: Metal Finisher’s Association of India, 2002), paper no. 42.

R. Duncan and T. Arney, Plat. Surf. Finish., 71 (1984), p. 49.

Author information

Authors and Affiliations

Additional information

For more information, contact Y.W. Riddle, UCT Coatings Inc., 7825 SW Ellipse Way, Stuart, FL 34997; (772) 223-6699; e-mail yriddle@uctcoatings.com.

Rights and permissions

About this article

Cite this article

Riddle, Y.W., Bailerare, T.O. Friction and wear reduction via an Ni-B electroless bath coating for metal alloys. JOM 57, 40–45 (2005). https://doi.org/10.1007/s11837-005-0080-7

Issue Date:

DOI: https://doi.org/10.1007/s11837-005-0080-7