Abstract

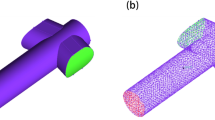

Slag entrainment in a continuous casting mold is one of the major causes of macro nonmetallic inclusions in continuous casting steel products. Stabilizing the level fluctuation is an important factor to improve steel quality. A new type of submerged entry nozzle (SEN) named self-braking SEN was designed. In the current study, water modeling experiments were performed to study the effect of self-braking SEN on level fluctuation in a continuous casting slab mold. The level position and the root mean square value of level fluctuation were analyzed through the online detection data. The results showed that the flow in the mold was more symmetrical and the tracer dispersion was more uniform. Moreover, the meniscus was also more uniform than the conventional nozzle with the self-braking SEN, especially at high casting speed.

Similar content being viewed by others

References

L. Zhang, Y. Wang, and X. Zuo, Metall. Mater. Trans. B 39, 534 (2008).

H. Bai and B.G. Thomas, Metall. Mater. Trans. B 32, 1143 (2001).

S. Yokoya, Y. Asako, S. Hara, and J. Szekely, ISIJ Int. 34, 883 (1994).

S. Yokoya, S. Haseo, S. Takagi, Y. Asako, J. Szekely, and S. Hara, Steelmaking Conference Proceedings, vol. 79 (Warrendale, PA: ISS, 1996), pp. 217–224.

S. Yokoya, S. Takagi, M. Iguchi, Y. Asako, R. Bestoff, and S. Hara, ISIJ Int. 38, 827 (1998).

S. Yokoya, S. Takagi, M. Iguchi, K. Marukawa, and S. Hara, Tetsu-to-Hagané 86, 259 (2000).

S. Yokoya, S. Takagi, M. Iguchi, K. Marukawa, and S. Hara, ISIJ Int. 40, 578 (2000).

S. Yokoya, S. Takagi, M. Iguchi, K. Marukawa, and S. Hara, ISIJ Int. 41, S47 (2001).

O. Nomura, Seramikkusu 35, 617 (2000).

N. Tsukamoto, Y. Kurashina, and K. Yanagawa, Taikabutsu 46, 215 (1994).

N. Tsukamoto, K. Ichikawa, E. Iida, A. Morita, and J. Inoue, 74th Steelmaking Conference Proceedings, vol. 74 (Warrendale, PA: ISS, 1991), pp. 803–808.

L. Zhang and B.G. Thomas (Paper presented at Proceeding of XXIV Steelmaking National Symposium, Mexico, 2003), pp. 184–198.

K. Morward, J. Watzinger, M. Stiftinger, H. Resch, and G. Shan, ISSTech2003 (Warrendale, PA: ISS, 2003), pp. 1135–1155.

B.G. Thomas, Continuous Casting, vol. 5, ed. A. Cramb (Pittsburgh, PA: AISE Steel Foundation, 2003), pp. 14.1–14.41.

M.R. Ozgu, W.E. Sattler, C.A. Farlow, and L.J. Lawrence, ISSTech2003, vol. Electric Furnace, Steelmaking (Warrendale, PA: ISS, 2003), pp. 31–40.

P.D. King, L.J. Heaslip, D. Xu, J.D. Dorricott, and Q.K. Robinson, ISSTech2003 Conference Proceedings, vol. Electric Furnace and Steelmaking (Warrendale, PA: ISS, 2003), pp. 265–282.

S. Inoue and M. Ogata, Proceedings of AISTech 2005 Iron & Steel Technology Conference and Exposition, vol. II (Warrendale, PA: AIST, 2005), pp. 193–200.

L. Zhang (Paper presented at AISTech 2010 Proceedings, vol. II, 2010), pp. 147–159.

Y. Chen, L. Zhang, L. Sun, A. Dong, B. Yu, S. Yang, J. Li, and S. Li (Paper presented at AISTech 2011 Proceedings, vol. II, 2011).

L. Zhang, Chinese patent (No. ZL 201020501151.2): Self-braking Nozzle for Slab Continuous Casting, 2011.

L. Zhang, Y. Wang, D. Zhou, X. Hu, and K. Qian (Paper presented at Proceedings of the Third International Conference on Continuous Casting of Steel in Developing Countries [CCC’04], CSM, Beijing, China, 2004), pp. 641–646.

L. Zhang, S. Yang, K. Cai, J. Li, X. Wan, and B.G. Thomas, Metall. Mater. Trans. B 38B, 63 (2007).

L. Zhang, S. Yang, X. Wang, K. Cai, J. Li, X. Wan, and B.G. Thomas, AISTech2004 (Warrendale, PA: ISS, 2004), pp. 879–894.

M.R. Amin and A. Mahajan, Numer. Heat Trans. Part A Appl. 46, 221 (2004).

M.P. Arruda and N. Lawson (Paper presented at Proceedings of ASME/JSME Joint Fluids Engineering Conference, vol. 2, 2003), pp. 2761–2768.

S.K. Dash, S.S. Mondal, and S.K. Ajmani, Int J. Numer. Methods Heat Fluid Flow 14, 606 (2004).

X. Wei Tian and G. Carlsson, Scand. J. Metall. 12, 121 (1983).

N.J. Lawson and M.R. Davidson, J. Fluids Eng. Trans. ASME 124, 535 (2002).

D. Gupta and A.K. Lahiri, Metall. Mater. Trans. B 25, 227 (1994).

A. Matsushita, K. Isogami, and K. Tsutsumi, Trans. ISIJ 28, 531 (1988).

T. Kato, M. Hara, A. Muto, S. Hiraki, and M. Kawamoto, ISIJ Int. 47, 840 (2007).

M. Kamal and Y. Sahai, Steel Research Int. 76, 44 (2005).

Acknowledgements

This research is supported by the High Quality Steel Consortium (HQSC) and the Laboratory of Green Process Metallurgy and Modeling (GPMM) at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Y., Zhang, L., Yang, S. et al. Water Modeling of Self-Braking Submerged Entry Nozzle Used for Steel Continuous Casting Mold. JOM 64, 1080–1086 (2012). https://doi.org/10.1007/s11837-012-0416-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0416-z